Understanding the Critical Role of Heat Treatment in Tool Casting for Enhanced Performance

Introduction: Heat Treatment and Tool Casting

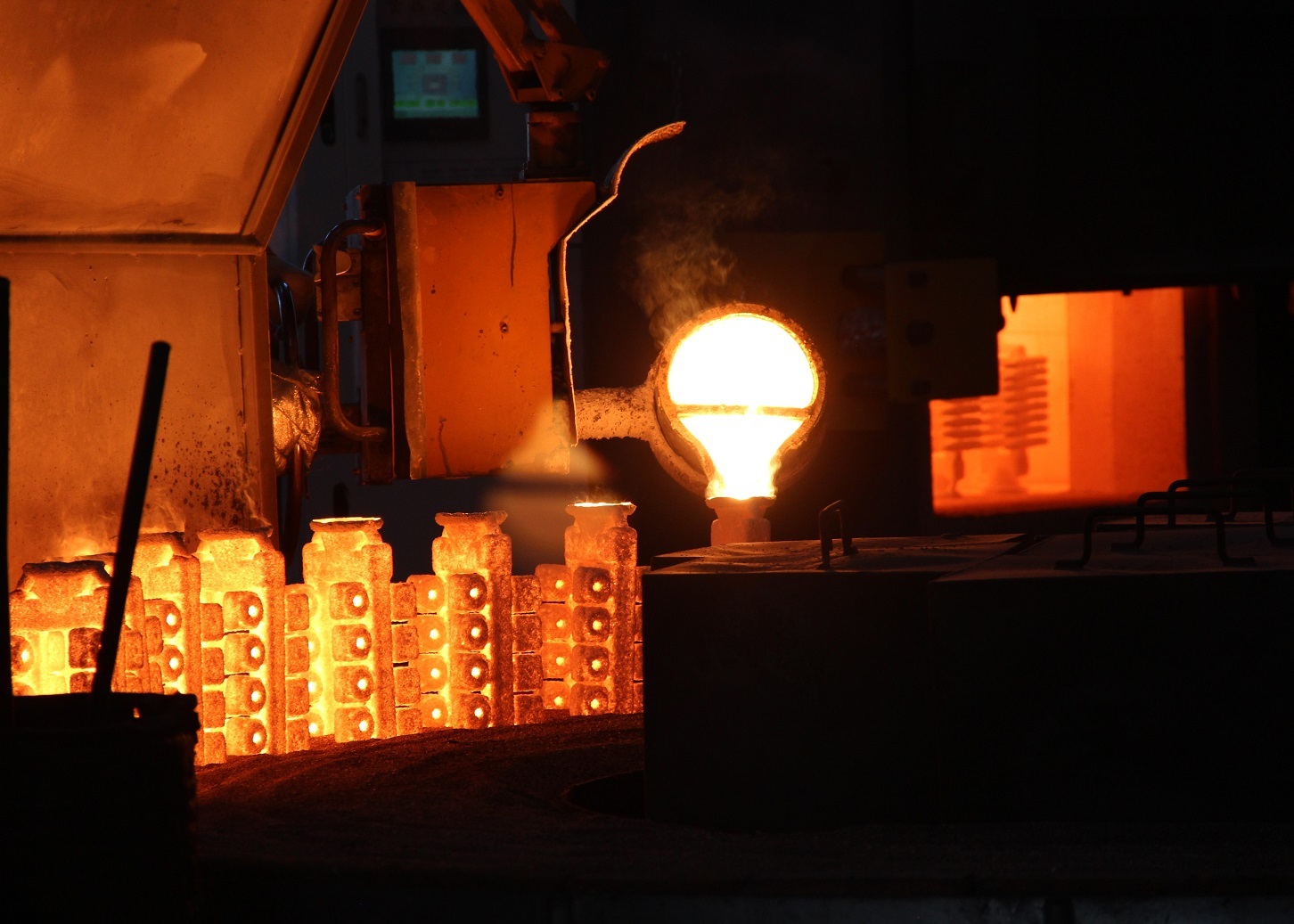

In the manufacturing realm, particularly in the production of metallic components, heat treatment tool casting plays a pivotal role in ensuring the quality and longevity of tools. Tool casting, which involves shaping molten metal into specific forms, can benefit immensely from the right heat treatment processes. This article aims to provide a comprehensive understanding of how heat treatment enhances tool casting, emphasizing its importance, methods, and advantages.

What is Heat Treatment?

Heat treatment is a controlled process that alters the physical and sometimes chemical properties of materials, particularly metals. This process involves heating and cooling the material in a specific environment to achieve desired characteristics. The primary objectives of heat treatment include:

- Enhancing strength and hardness: Heat treatment can significantly increase a material's resistance to deformation and wear.

- Improving ductility: By adjusting the microstructure, heat treatment can enhance the material's ability to deform without breaking.

- Refining grain structure: This process promotes uniformity in the material, leading to better performance.

Heat treatment encompasses various processes, including annealing, hardening, tempering, and normalizing, each serving unique purposes in the tool casting domain.

The Importance of Heat Treatment in Tool Casting

The significance of heat treatment in tool casting cannot be overstated. Here's why it is essential:

- Durability: Tools that undergo appropriate heat treatment exhibit increased resistance to wear and fatigue. This enhanced durability is essential for tools used in demanding environments.

- Precision: Heat treatment processes help in achieving precise dimensions and tolerances, which is critical in industrial applications.

- Stress Relief: Tool casting can introduce internal stresses in materials. Heat treatment helps relieve these stresses, preventing distortion during subsequent processes.

The integration of heat treatment in the tool casting process not only improves the performance of the tools but also extends their operational life, making it a critical step in manufacturing.

Key Methods of Heat Treatment

Several methods can be used in the heat treatment tool casting of tools. Each of these methods caters to specific requirements and material types:

1. Annealing

Annealing involves heating the material to a specific temperature and then allowing it to cool slowly. This method is primarily used to soften metals, relieve internal stresses, and improve ductility.

2. Hardening

Hardening is a process where the material is heated to a high temperature and then rapidly cooled (quenched), usually in water or oil. This method increases the hardness of the tool, making it more resistant to wear.

3. Tempering

Tempering follows hardening, where the hardened metal is reheated to a lower temperature. This process helps reduce brittleness while maintaining hardness.

4. Normalizing

Normalizing involves heating the material above its critical temperature and then allowing it to cool in air. This process helps refine the grain structure and improve mechanical properties.

5. Quenching

Quenching is a rapid cooling method that is essential in achieving high hardness levels in certain tool materials. The cooling medium (water, oil, etc.) plays a crucial role in the final properties of the tool.

Impact of Heat Treatment on Material Properties

Heat treatment significantly influences various material properties essential for tool performance:

1. Hardness

The hardness of a tool directly affects its wear resistance and performance. Proper heat treatment can enhance the hardness levels, allowing the tool to withstand greater stress during operation.

2. Toughness

Toughness refers to a material's ability to absorb energy and deform without fracturing. Heat treatment processes can improve toughness by balancing hardness and ductility.

3. Fatigue Resistance

Tools are often subjected to cyclic loading, which can lead to fatigue failure. Heat treatment improves fatigue resistance, making tools more reliable in demanding applications.

4. Wear Resistance

Wear resistance is critical for tools used in machining and cutting operations. Heat treatment enhances this property, ensuring longer tool life and lower operational costs.

Advantages of Heat Treatment for Tool Casting

The benefits of incorporating heat treatment into the tool casting process are manifold:

- Extended Tool Life: Proper heat-treated tools tend to have a longer life span, reducing the frequency of replacements and maintenance.

- Cost-Effectiveness: While heat treatment involves an additional step in manufacturing, the cost savings from extended tool life and reduced downtime can far outweigh the initial investment.

- Enhanced Performance: Tools that have undergone heat treatment offer superior performance characteristics, making them more efficient in their applications.

- Customization: By adjusting heat treatment parameters, manufacturers can tailor the properties of tools to meet specific requirements, providing significant flexibility in production.

Common Applications of Heat-Treated Components

Heat-treated tools and components find applications across various industries:

- Metalworking: Cutting tools, drills, and dies benefit significantly from heat treatment to enhance their performance.

- Construction: Tools used in construction, such as chisels and hammers, require durability and strength that heat treatment provides.

- Automotive: Components such as gears and shafts undergo heat treatment to improve their wear resistance and strength.

- Aerospace: The stringent requirements in the aerospace industry necessitate the use of heat-treated components for reliability and safety.

Challenges and Solutions in Heat Treatment

Despite its benefits, heat treatment comes with challenges:

1. Distortion

During heat treatment, components can warp or distort. To mitigate this, precise control of heating and cooling rates is essential.

2. Cracking

Improper heat treatment can lead to cracking. Utilizing the correct quenching medium and techniques can minimize this risk.

3. Cost of Equipment

The investment in heat treatment facilities can be significant. However, partnering with specialized service providers can be a cost-effective solution for many manufacturers.

Future Trends in Heat Treatment for Tool Casting

As technology advances, the field of heat treatment is evolving. Some future trends include:

- Automation and Industry 4.0: Integrating smart technology for monitoring and controlling heat treatment processes to enhance precision and reduce errors.

- Advanced Materials: Research into new alloys and materials that respond better to heat treatment, improving tool performance even further.

- Sustainable Practices: Developing eco-friendly heat treatment methods that reduce energy consumption and environmental impact.

Conclusion

The role of heat treatment tool casting in tool casting is indispensable for manufacturers seeking to enhance the performance and longevity of their tools. By understanding and implementing effective heat treatment methods, businesses can significantly improve the durability, strength, and efficiency of their products. As we move forward, embracing technological advancements and sustainable practices in heat treatment will further revolutionize the metalworking industry, ensuring that manufacturers meet the evolving demands of modern applications.

Development prospects of investment casting

The products obtained by investment casting are precise and complex, close to the final shape of the parts, and can be directly used without or with little machining. It is an advanced technology for near net formation and an excellent process technology in the casting industry, with a wide range of applications. It is suitable for casting various types of alloys, and the produced castings have higher dimensional accuracy and surface quality than other casting methods. Even complex, high-temperature resistant, and difficult to process castings can be cast using investment casting precision casting.

2024/10/08