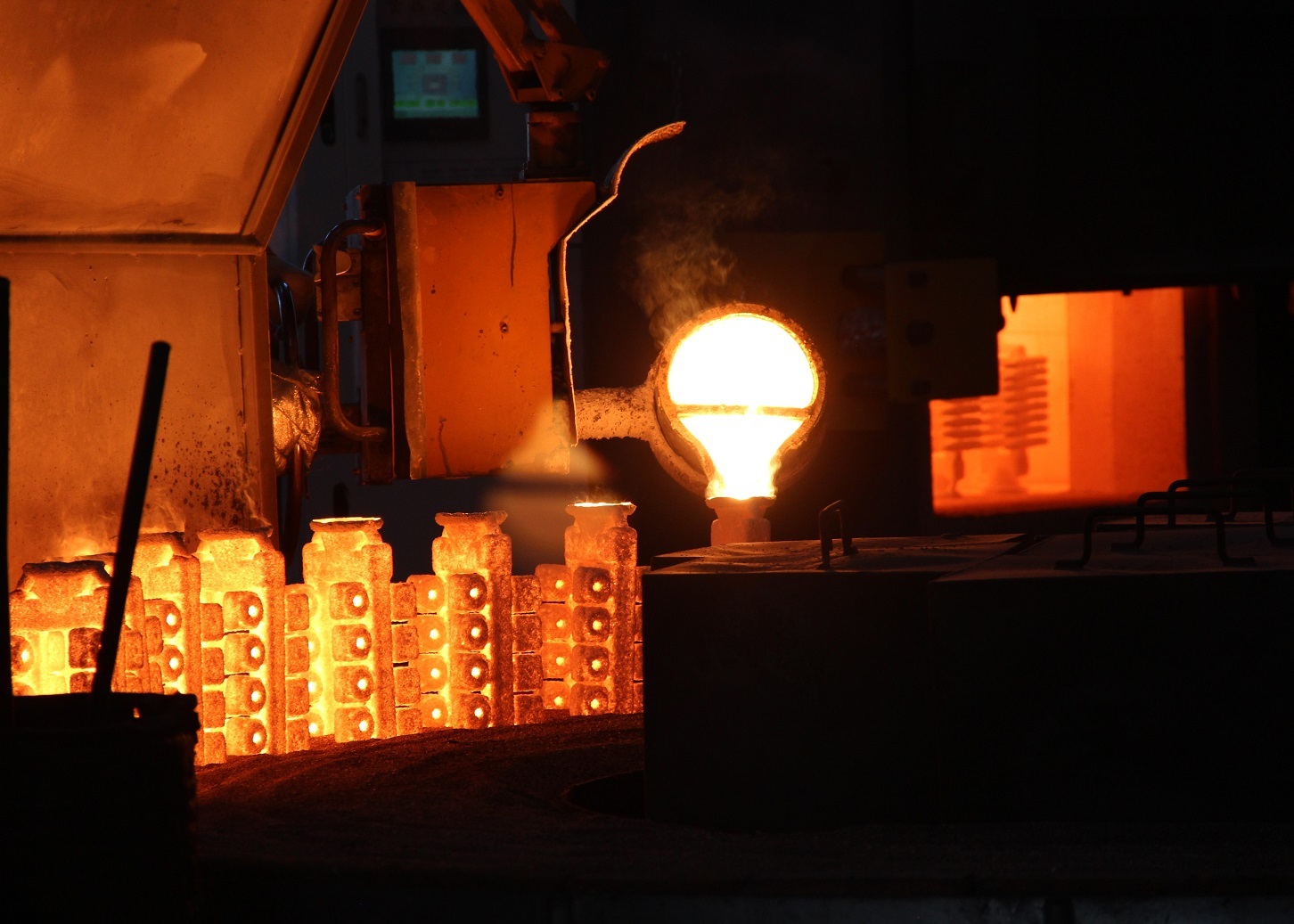

Dewax casting, also known as lost wax casting, is a sophisticated method widely used in the manufacturing of intricate and precise parts, including those required in food machinery. This technique involves creating a wax model of the desired part, which is then encased in a ceramic shell. Once the shell is formed, the wax is melted and drained away, leaving a cavity that is filled with molten metal. This process allows for the production of complex shapes and fine details that are often challenging to achieve with traditional casting methods.

In the food machinery industry, the reliability and cleanliness of components are paramount. Dewax casting can produce parts made from materials that meet stringent hygiene standards, which is essential for equipment used in food processing and handling. The ability to create seamless and smooth surfaces in dewax casting means that there are fewer crevices where bacteria can accumulate, making it easier to maintain sanitary conditions.

Another significant advantage of dewax casting is its ability to work with a variety of metals. Commonly used materials in this process include stainless steel and aluminum, both of which offer excellent corrosion resistance and durability. These properties are particularly important in food machinery, where equipment is frequently exposed to moisture, chemicals, and other harsh environments.

One of the key benefits of dewax casting is its efficiency in producing small to medium-sized batches of parts. The initial investment in creating the wax models and ceramic shells can be offset by the high-quality output and the reduced need for extensive machining. This efficiency not only saves time but also minimizes material waste, making it an environmentally friendly option for manufacturers.

Moreover, the dewax casting process allows for a high degree of design flexibility. Engineers and designers can easily modify the wax models to optimize the performance and functionality of the parts. This adaptability is crucial in the food machinery sector, where technological advancements and changing regulations require constant innovation.

In conclusion, dewax casting offers numerous advantages for producing food machinery parts, including precision, material versatility, and compliance with hygiene standards. As the manufacturing industry continues to evolve, understanding the intricacies of processes like dewax casting will be essential for professionals looking to stay competitive and meet the demands of modern food production. Embracing this technique can lead to improved product quality, enhanced efficiency, and a commitment to sustainability in manufacturing practices.

In the food machinery industry, the reliability and cleanliness of components are paramount. Dewax casting can produce parts made from materials that meet stringent hygiene standards, which is essential for equipment used in food processing and handling. The ability to create seamless and smooth surfaces in dewax casting means that there are fewer crevices where bacteria can accumulate, making it easier to maintain sanitary conditions.

Another significant advantage of dewax casting is its ability to work with a variety of metals. Commonly used materials in this process include stainless steel and aluminum, both of which offer excellent corrosion resistance and durability. These properties are particularly important in food machinery, where equipment is frequently exposed to moisture, chemicals, and other harsh environments.

One of the key benefits of dewax casting is its efficiency in producing small to medium-sized batches of parts. The initial investment in creating the wax models and ceramic shells can be offset by the high-quality output and the reduced need for extensive machining. This efficiency not only saves time but also minimizes material waste, making it an environmentally friendly option for manufacturers.

Moreover, the dewax casting process allows for a high degree of design flexibility. Engineers and designers can easily modify the wax models to optimize the performance and functionality of the parts. This adaptability is crucial in the food machinery sector, where technological advancements and changing regulations require constant innovation.

In conclusion, dewax casting offers numerous advantages for producing food machinery parts, including precision, material versatility, and compliance with hygiene standards. As the manufacturing industry continues to evolve, understanding the intricacies of processes like dewax casting will be essential for professionals looking to stay competitive and meet the demands of modern food production. Embracing this technique can lead to improved product quality, enhanced efficiency, and a commitment to sustainability in manufacturing practices.

Development prospects of investment casting

The products obtained by investment casting are precise and complex, close to the final shape of the parts, and can be directly used without or with little machining. It is an advanced technology for near net formation and an excellent process technology in the casting industry, with a wide range of applications. It is suitable for casting various types of alloys, and the produced castings have higher dimensional accuracy and surface quality than other casting methods. Even complex, high-temperature resistant, and difficult to process castings can be cast using investment casting precision casting.

2024/10/08