Textile machinery casting parts play a pivotal role in the garment manufacturing industry, serving as essential components that enhance the performance and longevity of various textile machines. These casting parts are typically made from metals such as iron or aluminum and are designed to withstand the rigors of the manufacturing process, which often involves high levels of stress and wear.

The manufacturing of textile machinery involves a variety of processes, including weaving, knitting, dyeing, and finishing. Each of these processes relies on specific types of machinery, all of which require high-quality casting parts to function effectively. For instance, casting parts may include frames, gears, and housings, all of which need to be robust and precisely engineered. The durability and accuracy of these casting components directly influence the overall efficiency and quality of the textile machinery, making them vital to the production line.

There are several types of casting processes used in the creation of textile machinery parts. Common methods include sand casting, investment casting, and die casting. Sand casting, for instance, is often favored for its cost-effectiveness and versatility, allowing for the production of large and complex parts. Investment casting, on the other hand, is known for its precision and ability to create intricate shapes, making it suitable for parts that require tight tolerances.

The selection of appropriate casting methods and materials is crucial because it impacts not only the performance of the textile machinery but also maintenance and repair costs. High-quality casting parts are designed to reduce the frequency of breakdowns, which can significantly enhance production efficiency. When machinery operates seamlessly, manufacturers can meet demands promptly while maintaining product quality.

Moreover, advancements in technology have led to the development of new materials and techniques that improve the casting process. Innovations such as computer-aided design (CAD) and simulation software enable manufacturers to create more complex designs with improved accuracy. These advancements ensure that casting parts not only meet the required specifications but also adapt to the evolving needs of the textile industry.

In conclusion, textile machinery casting parts are a fundamental component in garment manufacturing, influencing the performance and reliability of production equipment. Their design, material selection, and manufacturing processes demand careful consideration to ensure that textile machinery operates efficiently and effectively. As the industry continues to evolve, staying informed about advancements in casting technologies will be key for manufacturers aiming to improve their production capabilities and maintain competitiveness in the market.

The manufacturing of textile machinery involves a variety of processes, including weaving, knitting, dyeing, and finishing. Each of these processes relies on specific types of machinery, all of which require high-quality casting parts to function effectively. For instance, casting parts may include frames, gears, and housings, all of which need to be robust and precisely engineered. The durability and accuracy of these casting components directly influence the overall efficiency and quality of the textile machinery, making them vital to the production line.

There are several types of casting processes used in the creation of textile machinery parts. Common methods include sand casting, investment casting, and die casting. Sand casting, for instance, is often favored for its cost-effectiveness and versatility, allowing for the production of large and complex parts. Investment casting, on the other hand, is known for its precision and ability to create intricate shapes, making it suitable for parts that require tight tolerances.

The selection of appropriate casting methods and materials is crucial because it impacts not only the performance of the textile machinery but also maintenance and repair costs. High-quality casting parts are designed to reduce the frequency of breakdowns, which can significantly enhance production efficiency. When machinery operates seamlessly, manufacturers can meet demands promptly while maintaining product quality.

Moreover, advancements in technology have led to the development of new materials and techniques that improve the casting process. Innovations such as computer-aided design (CAD) and simulation software enable manufacturers to create more complex designs with improved accuracy. These advancements ensure that casting parts not only meet the required specifications but also adapt to the evolving needs of the textile industry.

In conclusion, textile machinery casting parts are a fundamental component in garment manufacturing, influencing the performance and reliability of production equipment. Their design, material selection, and manufacturing processes demand careful consideration to ensure that textile machinery operates efficiently and effectively. As the industry continues to evolve, staying informed about advancements in casting technologies will be key for manufacturers aiming to improve their production capabilities and maintain competitiveness in the market.

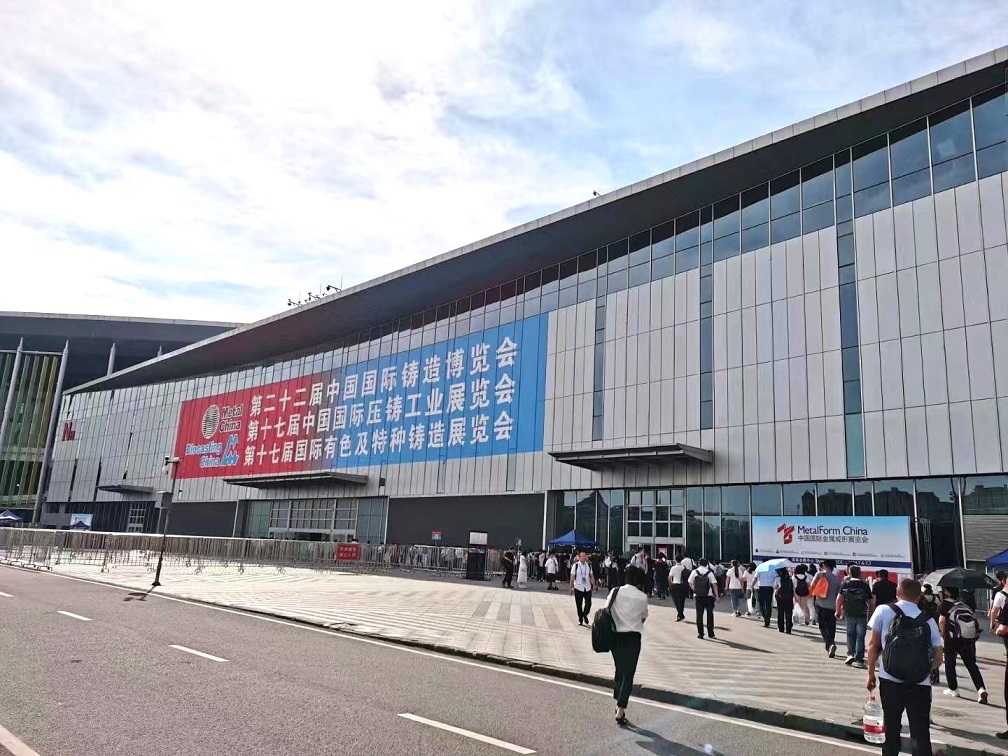

2024 Shanghai International Foundry Expo

In December 2024, Dalian Sakabe met new friends at the Shanghai International Foundry Expo

2024/12/30

Sakabe production exchange meeting between Chinese and Japanese teams

A stable international cooperation relationships are particularly precious in the increasingly severe international environment. Sakabe production teams from China and Japan held a production exchange meeting recently.

2024/10/08

2024/10/08