In the realm of manufacturing, particularly within the mechanical hardware processing industry, die-casting plays a pivotal role, especially for food machinery. Die-casting parts are essential for creating robust, precise, and complex shapes that meet the stringent standards required in food processing applications. This article delves into the importance of die-casting parts in food machinery and how they can optimize production processes.

Die-casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique is particularly beneficial for producing intricate parts that require high dimensional accuracy and a smooth finish. In the food machinery sector, where hygiene and performance are paramount, die-casting parts offer a reliable solution. These components can be made from various materials, including aluminum, zinc, and magnesium, each selected for its specific properties suited to food processing environments.

One of the key advantages of using die-casting parts in food machinery is their durability. The high strength-to-weight ratio of die-cast components ensures that machines can withstand the rigors of continual operation without significant wear or degradation. This is particularly relevant in food processing, where equipment must frequently endure harsh cleaning regimes and high operational demands.

Furthermore, die-casting parts promote efficiency in manufacturing due to their ability to be produced in high volumes with minimal waste. The precision of the die-casting process allows for tight tolerances, reducing the need for extensive machining and secondary operations. This not only streamlines production but also lowers costs associated with material waste and labor.

The versatility of die-casting also allows manufacturers to innovate continuously. With the capability to create complex geometries, food machinery can be designed to enhance functionality while maintaining compliance with health and safety standards. This adaptability is crucial in an ever-evolving industry where consumer demands and regulatory requirements are continually changing.

Moreover, die-casting parts can be easily integrated into automated systems, which are becoming increasingly prevalent in food processing. Automation not only improves production rates but also ensures consistent quality, which is vital in maintaining food safety and consumer trust.

In conclusion, the integration of food machinery die-casting parts into manufacturing processes offers numerous benefits, including enhanced durability, efficiency, and adaptability. As the food processing industry continues to grow and evolve, leveraging the advantages of die-casting will be essential for manufacturers aiming to stay competitive and meet the high standards expected in today’s market. Understanding these benefits is crucial for businesses looking to optimize their operations and meet the demands of an increasingly sophisticated consumer base.

Die-casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique is particularly beneficial for producing intricate parts that require high dimensional accuracy and a smooth finish. In the food machinery sector, where hygiene and performance are paramount, die-casting parts offer a reliable solution. These components can be made from various materials, including aluminum, zinc, and magnesium, each selected for its specific properties suited to food processing environments.

One of the key advantages of using die-casting parts in food machinery is their durability. The high strength-to-weight ratio of die-cast components ensures that machines can withstand the rigors of continual operation without significant wear or degradation. This is particularly relevant in food processing, where equipment must frequently endure harsh cleaning regimes and high operational demands.

Furthermore, die-casting parts promote efficiency in manufacturing due to their ability to be produced in high volumes with minimal waste. The precision of the die-casting process allows for tight tolerances, reducing the need for extensive machining and secondary operations. This not only streamlines production but also lowers costs associated with material waste and labor.

The versatility of die-casting also allows manufacturers to innovate continuously. With the capability to create complex geometries, food machinery can be designed to enhance functionality while maintaining compliance with health and safety standards. This adaptability is crucial in an ever-evolving industry where consumer demands and regulatory requirements are continually changing.

Moreover, die-casting parts can be easily integrated into automated systems, which are becoming increasingly prevalent in food processing. Automation not only improves production rates but also ensures consistent quality, which is vital in maintaining food safety and consumer trust.

In conclusion, the integration of food machinery die-casting parts into manufacturing processes offers numerous benefits, including enhanced durability, efficiency, and adaptability. As the food processing industry continues to grow and evolve, leveraging the advantages of die-casting will be essential for manufacturers aiming to stay competitive and meet the high standards expected in today’s market. Understanding these benefits is crucial for businesses looking to optimize their operations and meet the demands of an increasingly sophisticated consumer base.

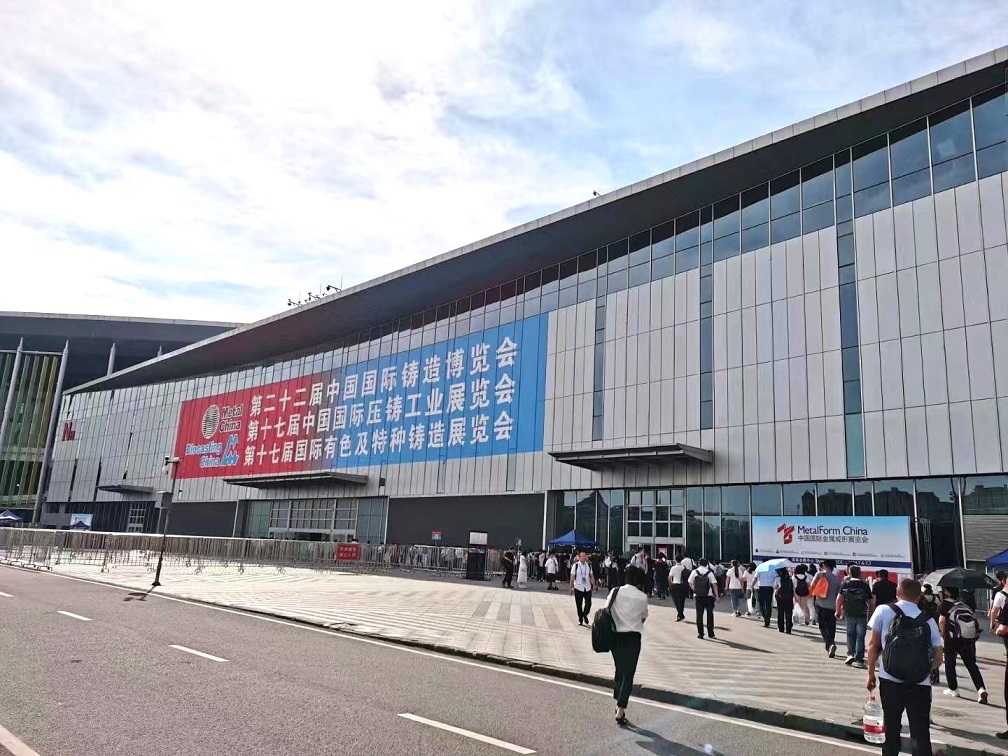

2024 Shanghai International Foundry Expo

In December 2024, Dalian Sakabe met new friends at the Shanghai International Foundry Expo

2024/12/30

Sakabe production exchange meeting between Chinese and Japanese teams

A stable international cooperation relationships are particularly precious in the increasingly severe international environment. Sakabe production teams from China and Japan held a production exchange meeting recently.

2024/10/08

2024/10/08