Unlocking Precision: The Role of Casting in Medical Tool Parts

1. Introduction to Casting in Medical Tool Manufacturing

Casting is a fundamental manufacturing process that is essential in producing medical tool parts. This technique involves pouring molten material into a mold to create a desired shape, offering unparalleled precision and complexity. In healthcare, where accuracy can mean the difference between life and death, the significance of medical tool parts casting cannot be overstated. This article delves into the various aspects of casting, its methodologies, and its critical role in enhancing the quality of medical tools.

2. Importance of Precision in Medical Tools

Precision in medical tools is paramount. These tools are often used in sensitive environments where errors can lead to severe consequences, including improper diagnoses or surgical complications. High precision ensures effective performance, safety, and reliability of medical devices. This section discusses:

- The critical role of precision in surgical instruments, diagnostic tools, and implants.

- Case studies demonstrating the impact of precision on patient outcomes.

- Regulatory standards governing the precision of medical tools.

3. Common Casting Methods Used in Medical Tool Production

Casting methods vary in complexity and applicability, each with its unique advantages. Understanding these methods is vital for manufacturers aiming to produce high-quality medical tools.

3.1 Sand Casting

Sand casting is one of the oldest and most widely used methods. This process involves creating a mold from sand and then pouring molten metal into it. The advantages of sand casting include:

- Cost-Effectiveness: Lower tooling costs make it ideal for low-volume production.

- Flexibility: Suitable for a wide range of materials.

- Size Capability: Can produce large and complex parts.

However, it may not offer the precision needed for all medical applications.

3.2 Investment Casting

Investment casting, also known as lost wax casting, is renowned for its ability to create highly detailed components with excellent surface finish. The process involves creating a wax pattern, covering it with a ceramic shell, and then melting the wax away. Key benefits include:

- High Precision: Ideal for intricate designs.

- Reduced Material Wastage: Optimizes the use of raw materials.

- Consistency: Produces parts with tight tolerances.

This method is particularly advantageous in creating surgical instruments and implants.

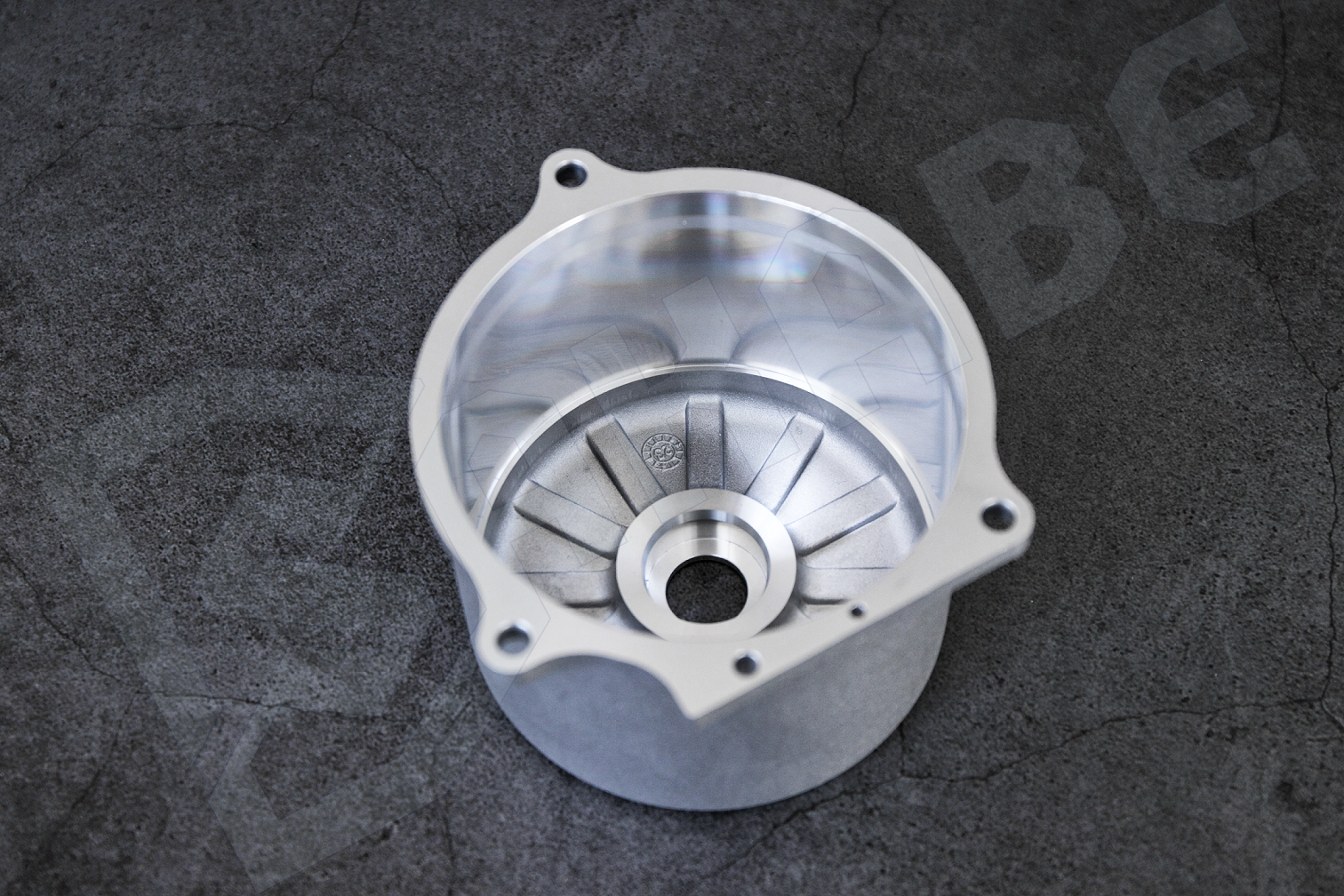

3.3 Die Casting

Die casting is a high-pressure casting method that produces parts with exceptional accuracy and smooth finishes. It involves forcing molten metal into a mold cavity. Advantages include:

- High-Speed Production: Suitable for mass production.

- Dimensional Accuracy: Ensures uniformity across large batches.

- Complex Geometries: Capable of creating highly intricate shapes.

Die casting is commonly utilized for components requiring precision, such as housings and fittings for medical devices.

4. Advantages of Using Casting for Medical Tools

Casting offers numerous advantages that make it an attractive option for producing medical tools. These benefits include:

- Design Freedom: Casting can accommodate complex shapes that are difficult to achieve with other manufacturing methods.

- Material Versatility: A wide range of materials, including high-strength alloys and biocompatible metals, can be used.

- Cost Efficiency: Particularly for large-scale production runs, casting can be more economical than machining.

Moreover, casting allows for the manufacture of bespoke tools tailored to specific medical applications, enhancing functionality.

5. Material Selection for Casting in Medical Applications

Selecting the appropriate material is crucial in the casting process. The choice of material impacts the performance, durability, and safety of medical tools. Common materials used in casting medical parts include:

- Stainless Steel: Known for its corrosion resistance and strength, ideal for surgical instruments.

- Titanium Alloys: Highly biocompatible, making them suitable for implants.

- Nickel-Based Alloys: Excellent for high-temperature applications and resistance to wear.

This section also discusses compliance with regulatory standards and material certifications necessary for medical applications.

6. Ensuring Quality and Precision in Casted Medical Parts

Quality control is essential in the casting process for medical tools. Rigorous testing and inspection methods ensure that the final products meet all necessary standards. This section highlights:

- Non-Destructive Testing (NDT): Techniques such as X-ray and ultrasonic testing to detect internal flaws.

- Dimensional Inspection: Using tools like coordinate measuring machines (CMM) to verify sizes and tolerances.

- Regulatory Compliance: Adhering to standards set by organizations like the FDA and ISO.

Implementing these quality control measures guarantees that medical tools not only meet specifications but also ensure patient safety.

7. Future Trends in Casting for Medical Tool Manufacturing

The future of casting in medical tool manufacturing is poised for significant advancements. Key trends include:

- Additive Manufacturing Integration: Combining casting with 3D printing technologies for enhanced design capabilities.

- Smart Materials: Research into materials that respond to environmental changes, improving tool functionality.

- Sustainable Practices: Emphasis on eco-friendly materials and processes to reduce waste and energy consumption.

Staying abreast of these trends allows manufacturers to remain competitive and innovate within the medical sector.

8. Conclusion

In the ever-evolving landscape of medical tool manufacturing, medical tool parts casting stands out as a critical process that ensures precision, reliability, and innovation. As we have explored, the various casting methods each bring unique advantages, enabling manufacturers to create high-quality medical tools essential for patient care. By understanding the intricacies of casting and embracing advancements in materials and technology, we can continue to improve the safety and effectiveness of medical devices. The future of casting in this industry appears bright, promising continued enhancements in both practice and patient outcomes.

Introduction to investment casting manufacturing technique

Investment casting, also known as wax loss casting, is a long-standing metal forming process. The copper ban during the Spring and Autumn period in China was the earliest known lost wax casting method. The first step is to make a mold, using the mold to inject liquid wax into the mold to form a wax mold. Then, the wax mold is pasted into a pouring system according to the casting process, and the entire pouring system is made into a silica sol shell. After dewaxing, the entire shell becomes a cavity, and the cavity shell can be poured with molten steel after calcination. After cooling, the steel material product is formed. Subsequently, through processes such as cutting and grinding, sandblasting, heat treatment, correction, welding repair, electroplating, and machining, the cast products required by the customer are formed.

2024/10/08

Dalian is a beautiful coastal city in Northeast China, with beautiful scenery and pleasant climate. It is an important industrial production base, an international shipping center in Northeast Asia.

2024/07/11

Dalian Sakabe has own foundry factory and focus on providing high-quality precision casting products to domestic and foreign customers since its establishment in 2005.

2024/10/08

The Crucial Role of Casting Material Trays in Advanced Manufacturing

In the ever-evolving landscape of manufacturing, optimizing heat treatment processes through the strategic use of casting material trays is paramount

2025/09/19