In the manufacturing and machining industry, the casting of heat treatment material trays and frames is a critical aspect of producing high-quality products. These trays and frames are essential for the safe and efficient handling of materials during heat treatment processes. Understanding the casting methods and materials can significantly impact production efficiency and product performance.

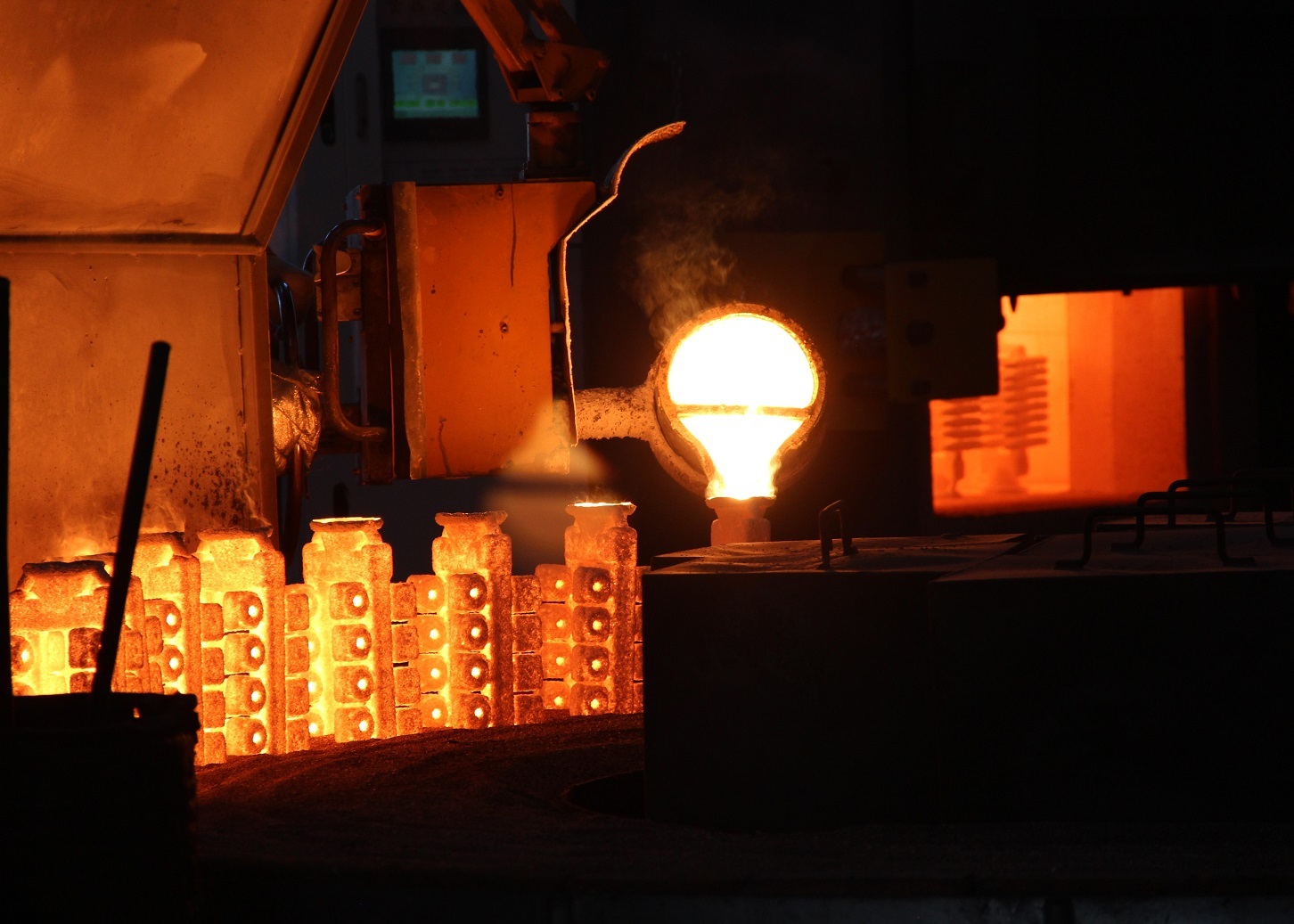

Casting is a technique that involves pouring molten metal into a mold, allowing it to solidify and form a specific shape. When it comes to heat treatment material trays and frames, the choice of casting material is crucial. Common materials used include aluminum, steel, and various alloys, each with their own properties that may influence thermal conductivity, strength, and weight. For instance, aluminum is lightweight and has excellent thermal conductivity, making it suitable for applications requiring rapid heating and cooling. Conversely, steel offers greater strength and durability, which may be necessary for more demanding environments.

The design of trays and frames also plays a vital role in their effectiveness during heat treatment. Proper design must account for factors such as load distribution, thermal expansion, and ease of handling. An optimized design can prevent warping or failure during high-temperature operations, which is crucial for maintaining the integrity of the heat treatment process.

Additionally, the casting process itself can further enhance the quality of these components. Techniques such as sand casting, investment casting, and die casting each have unique advantages and limitations. Sand casting, for example, is highly versatile and cost-effective for producing large quantities, while investment casting offers superior surface finish and precision for complex designs. Understanding these processes allows manufacturers to choose the most suitable method for their specific needs.

Quality control during the casting process is another essential consideration. Implementing rigorous inspection and testing protocols ensures that the trays and frames meet industry standards and specifications. This not only enhances the reliability of the products but also minimizes the risk of failures during heat treatment operations, which can lead to costly downtime and material loss.

In conclusion, casting for heat treatment material trays and frames is a multifaceted process that requires careful consideration of materials, design, and production methods. Manufacturers in the machining and hardware processing sectors can leverage this understanding to optimize their products, ultimately leading to improved performance and customer satisfaction. By focusing on these key areas, businesses can ensure they remain competitive in the evolving landscape of manufacturing.

Casting is a technique that involves pouring molten metal into a mold, allowing it to solidify and form a specific shape. When it comes to heat treatment material trays and frames, the choice of casting material is crucial. Common materials used include aluminum, steel, and various alloys, each with their own properties that may influence thermal conductivity, strength, and weight. For instance, aluminum is lightweight and has excellent thermal conductivity, making it suitable for applications requiring rapid heating and cooling. Conversely, steel offers greater strength and durability, which may be necessary for more demanding environments.

The design of trays and frames also plays a vital role in their effectiveness during heat treatment. Proper design must account for factors such as load distribution, thermal expansion, and ease of handling. An optimized design can prevent warping or failure during high-temperature operations, which is crucial for maintaining the integrity of the heat treatment process.

Additionally, the casting process itself can further enhance the quality of these components. Techniques such as sand casting, investment casting, and die casting each have unique advantages and limitations. Sand casting, for example, is highly versatile and cost-effective for producing large quantities, while investment casting offers superior surface finish and precision for complex designs. Understanding these processes allows manufacturers to choose the most suitable method for their specific needs.

Quality control during the casting process is another essential consideration. Implementing rigorous inspection and testing protocols ensures that the trays and frames meet industry standards and specifications. This not only enhances the reliability of the products but also minimizes the risk of failures during heat treatment operations, which can lead to costly downtime and material loss.

In conclusion, casting for heat treatment material trays and frames is a multifaceted process that requires careful consideration of materials, design, and production methods. Manufacturers in the machining and hardware processing sectors can leverage this understanding to optimize their products, ultimately leading to improved performance and customer satisfaction. By focusing on these key areas, businesses can ensure they remain competitive in the evolving landscape of manufacturing.

Development prospects of investment casting

The products obtained by investment casting are precise and complex, close to the final shape of the parts, and can be directly used without or with little machining. It is an advanced technology for near net formation and an excellent process technology in the casting industry, with a wide range of applications. It is suitable for casting various types of alloys, and the produced castings have higher dimensional accuracy and surface quality than other casting methods. Even complex, high-temperature resistant, and difficult to process castings can be cast using investment casting precision casting.

2024/10/08