Enhancing Industrial Efficiency with Heat Treatment Fixtures

Heat treatment fixtures are integral components used in the process of heat treatment, which is a crucial procedure utilized in metalworking and manufacturing. These fixtures serve multiple purposes, including the proper positioning of parts, ensuring uniform heating or cooling, and maintaining the mechanical integrity of the components throughout the treatment process. By understanding heat treatment fixtures, professionals in the industrial equipment and components sector can enhance the performance of their tools and fixtures.

The primary function of heat treatment fixtures is to support and secure the workpieces during the heating and cooling phases. A well-designed fixture ensures that the parts remain stable, preventing warping or distortion that could occur due to uneven heating. This is particularly important when treating materials that are sensitive to temperature changes, such as steel or aluminum alloys. Properly implemented, these fixtures help achieve consistent results, which is essential for industries relying on precision engineering.

Moreover, heat treatment fixtures can be tailored to accommodate various shapes and sizes of components. Customization is key in ensuring that the fixtures align with the specific requirements of the heat treatment process, whether it involves hardening, annealing, or tempering. The design of these fixtures must also consider factors such as heat transfer rates, airflow, and the specific techniques employed in the heat treatment process.

Another essential aspect of heat treatment fixtures is their durability. Given that they are subjected to extreme temperatures and varying environmental conditions, these components must be constructed from high-quality materials that can withstand such stresses. Selecting the right materials not only prolongs the lifespan of the fixtures but also guarantees that they perform effectively under challenging conditions.

In addition to physical design and material considerations, manufacturers must also ensure that heat treatment fixtures comply with industry standards and regulations. Adhering to best practices in design and construction reflects a commitment to quality and safety, which can significantly impact overall operational efficiency. Organizations that prioritize these factors often see improved outcomes in their heat treatment processes, leading to higher quality finished products.

Heat treatment fixtures play a pivotal role in enhancing the efficiency and effectiveness of the heat treatment process in the industrial sector. By securing and stabilizing components during treatment, ensuring uniform heat distribution, and accommodating various sizes and shapes, these fixtures allow for precision and consistency. Understanding the importance and functionality of heat treatment fixtures is essential for professionals in the tools and fixtures industry, as it directly correlates with the performance and reliability of the equipment they produce.

Introduction to investment casting manufacturing technique

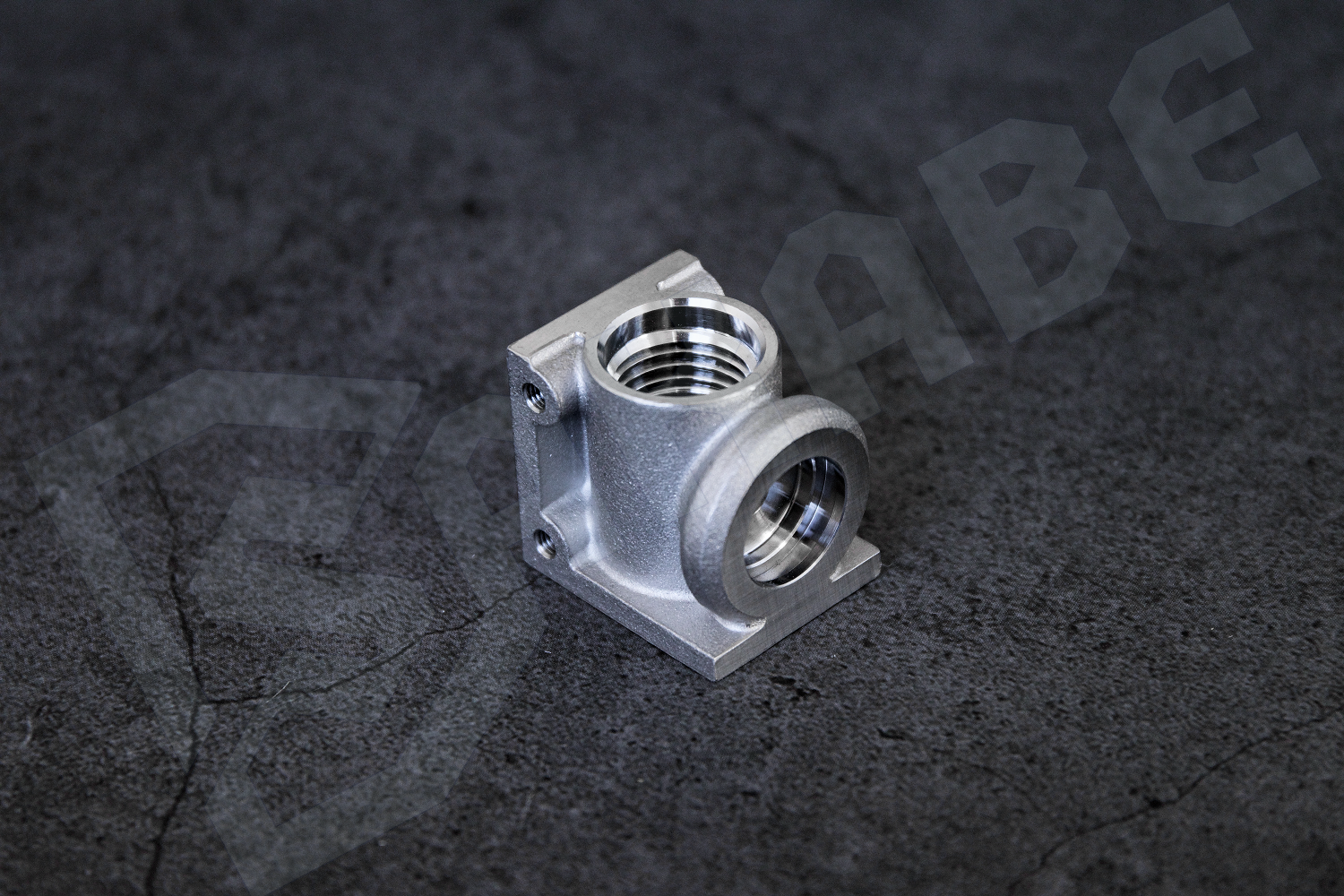

Investment casting, also known as wax loss casting, is a long-standing metal forming process. The copper ban during the Spring and Autumn period in China was the earliest known lost wax casting method. The first step is to make a mold, using the mold to inject liquid wax into the mold to form a wax mold. Then, the wax mold is pasted into a pouring system according to the casting process, and the entire pouring system is made into a silica sol shell. After dewaxing, the entire shell becomes a cavity, and the cavity shell can be poured with molten steel after calcination. After cooling, the steel material product is formed. Subsequently, through processes such as cutting and grinding, sandblasting, heat treatment, correction, welding repair, electroplating, and machining, the cast products required by the customer are formed.

2024/10/08

Dalian is a beautiful coastal city in Northeast China, with beautiful scenery and pleasant climate. It is an important industrial production base, an international shipping center in Northeast Asia.

2024/07/11

Dalian Sakabe has own foundry factory and focus on providing high-quality precision casting products to domestic and foreign customers since its establishment in 2005.

2024/10/08

The Crucial Role of Casting Material Trays in Advanced Manufacturing

In the ever-evolving landscape of manufacturing, optimizing heat treatment processes through the strategic use of casting material trays is paramount

2025/09/19