Why Medical Tool Die-Casting Parts Are Essential for Precision and Efficiency in Healthcare Manufacturing

Die-casting is a manufacturing process that has gained significant traction in producing precision components used in various industries, including the medical field. Chinese medical tool die-casting parts are integral to creating high-quality medical devices and instruments. The die-casting process allows for the production of complex shapes and designs with high dimensional accuracy, making it ideal for medical applications where precision is paramount.

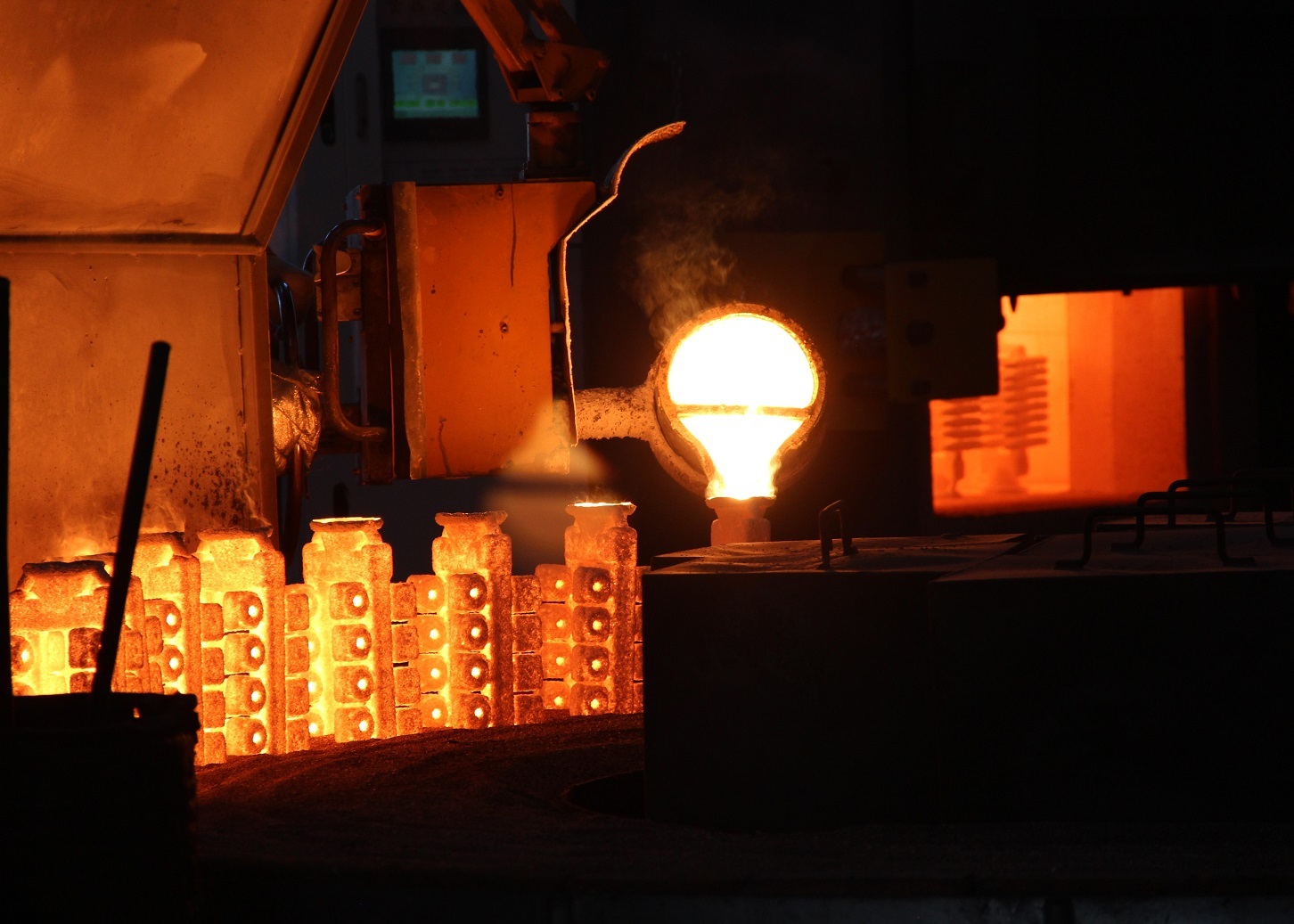

The die-casting method involves injecting molten metal into a mold, where it cools and solidifies to form the final part. This process is particularly beneficial for producing components that require intricate details and robust mechanical properties. In the medical industry, these die-casting parts are commonly used in surgical instruments, diagnostic devices, and various other medical tools that demand high reliability and durability.

One of the key advantages of using die-casting in the production of medical tool parts is the ability to achieve a smooth surface finish and consistent wall thickness, which is crucial for ensuring the sterility and effectiveness of medical devices. Moreover, the materials used in die-casting, such as aluminum and zinc alloys, offer excellent strength-to-weight ratios and corrosion resistance, essential attributes for medical tools that must withstand repeated use and sterilization processes.

Another significant aspect of Chinese medical tool die-casting parts is their cost-efficiency. The high production rates achievable through die-casting can lower overall manufacturing costs while maintaining the quality of the components. This efficiency is particularly important in the fast-paced medical industry, where timely production can directly impact patient care and outcomes.

Furthermore, as the demand for advanced medical technologies continues to grow, the importance of precision-engineered components will only increase. Manufacturers of medical tools are increasingly relying on die-casting techniques to meet the stringent regulatory standards and performance expectations set by healthcare providers and regulatory bodies.

In summary, Chinese medical tool die-casting parts play a vital role in the manufacturing of medical devices and instruments. Their unique properties, such as high precision, excellent surface finish, and cost-effectiveness, make them indispensable in the medical field. As technology continues to evolve, the role of die-casting in producing high-quality medical components will undoubtedly expand, further enhancing the capabilities of medical professionals to deliver effective patient care. Understanding these components is crucial for anyone involved in the medical manufacturing sector, as they are foundational to the future of healthcare technology.

Development prospects of investment casting

The products obtained by investment casting are precise and complex, close to the final shape of the parts, and can be directly used without or with little machining. It is an advanced technology for near net formation and an excellent process technology in the casting industry, with a wide range of applications. It is suitable for casting various types of alloys, and the produced castings have higher dimensional accuracy and surface quality than other casting methods. Even complex, high-temperature resistant, and difficult to process castings can be cast using investment casting precision casting.

2024/10/08