Unveiling the Secrets of the Best Textile Machinery Parts Casting

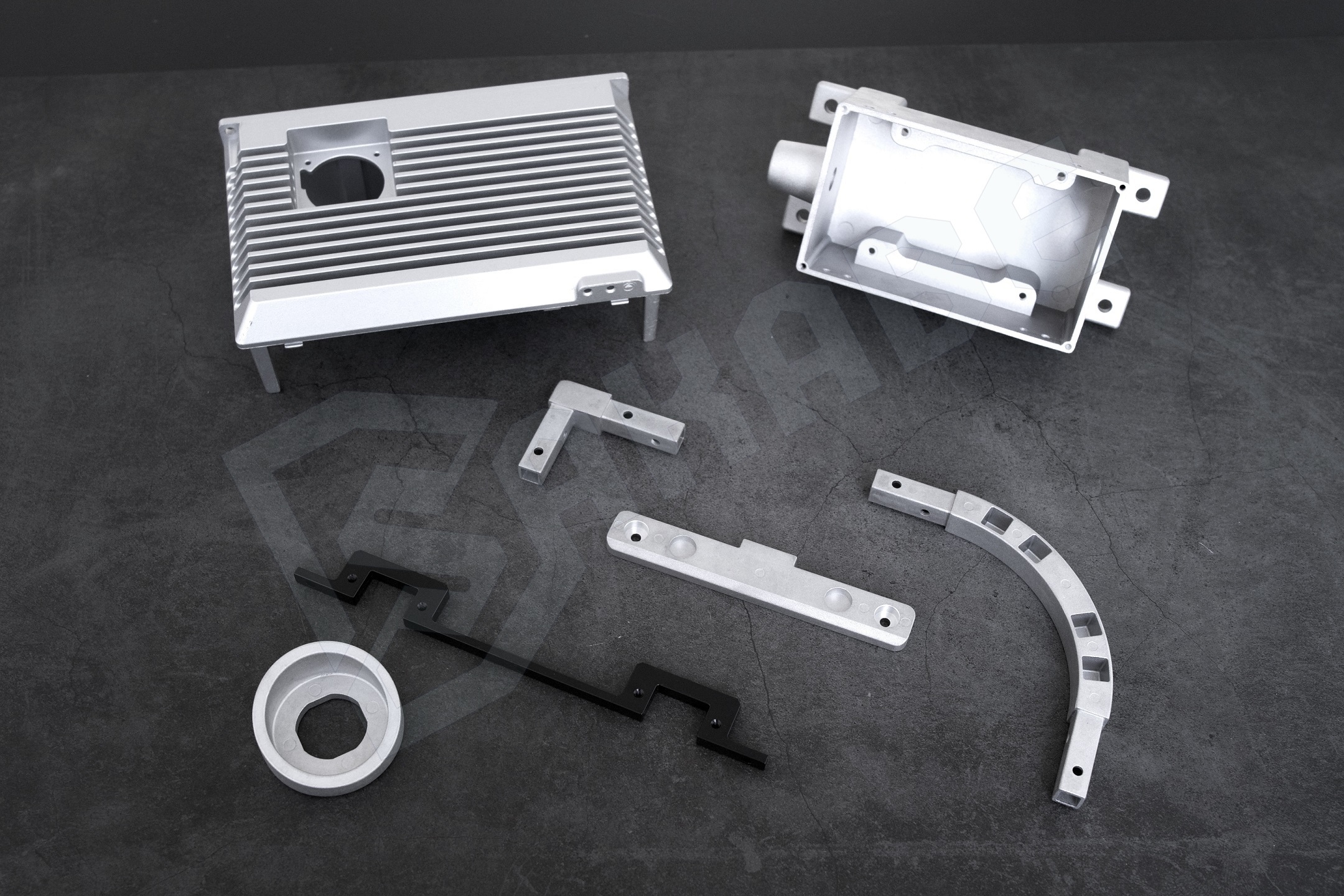

1. Understanding Textile Machinery Parts Casting

Casting is a fundamental process in manufacturing textile machinery parts. It involves pouring molten material into a mold to create solid components, which are essential for various functions in textile production. Understanding the nuances of casting can lead to the production of superior-quality machinery parts that enhance efficiency and longevity.

2. Importance of Quality Casting in Textile Machinery

Quality casting is critical in textile machinery due to the high-stress environments in which these machines operate. Durable and reliable components minimize downtime and maintenance costs. High-quality casting ensures that parts can withstand the rigors of textile manufacturing, leading to increased productivity and reduced operational costs.

3. Materials Used in Textile Machinery Parts Casting

The choice of materials is crucial in the casting process. Different materials offer varying benefits in terms of strength, durability, and cost.

3.1. Types of Metals for Casting

Common metals used in the casting of textile machinery parts include iron, aluminum, and steel. Each of these materials has unique properties that make them suitable for different applications. For instance, cast iron is known for its excellent wear resistance, while aluminum is favored for its lightweight characteristics.

3.2. Alloys and Their Applications

Alloys play a significant role in casting, as they are often tailored to meet specific requirements. Bronze and brass, for example, are alloys that provide excellent corrosion resistance, making them ideal for parts that come into contact with chemicals in textiles.

4. The Casting Process Explained

The casting process comprises several steps, each critical to ensuring the quality of the final product.

4.1. Sand Casting vs. Die Casting

Sand casting is one of the most traditional methods, allowing for intricate designs and larger parts. In contrast, die casting is suitable for producing high volumes of smaller parts with great precision. The choice between these methods depends on production requirements and design specifications.

4.2. Investment Casting Techniques

Investment casting, also known as lost-wax casting, allows for the creation of highly detailed parts. This technique is particularly useful for complex geometries and tight tolerances required in textile machinery components.

5. Best Practices for Textile Machinery Parts Casting

Implementing best practices in the casting process is vital for achieving optimal results.

5.1. Inspection and Quality Control

Regular inspection and adherence to quality control standards ensure that each component meets the required specifications. Non-destructive testing methods can be employed to assess the integrity of cast parts without causing damage.

5.2. Choosing the Right Foundry

Selecting a reputable foundry can significantly impact the quality of the casting. Look for foundries with experience in textile machinery parts and a proven track record of quality.

6. Innovations in Textile Machinery Parts Casting

The casting industry is evolving with technological advancements that enhance production efficiency and quality.

6.1. 3D Printing in Casting

3D printing has emerged as a revolutionary technique in casting. It allows for rapid prototyping and the production of complex parts that traditional methods cannot achieve. This innovation has the potential to significantly reduce lead times and costs.

6.2. Automation and Robotics

The integration of automation and robotics in the casting process increases precision and efficiency. Automated systems can handle repetitive tasks such as pouring and molding, reducing human error and improving productivity.

7. Challenges in Parts Casting for Textile Machinery

Despite advancements, challenges persist in the casting of textile machinery parts. These include maintaining dimensional accuracy, managing costs, and ensuring the integrity of materials.

Understanding the intricacies of textile machinery parts casting is essential for achieving high-quality components that enhance productivity and durability in textile manufacturing. By focusing on material selection, embracing innovative casting techniques, and adhering to best practices, manufacturers can unlock the full potential of their machinery. As the industry continues to evolve, staying informed about new technologies and methods will ensure a competitive edge in the market.

Introduction to investment casting manufacturing technique

Investment casting, also known as wax loss casting, is a long-standing metal forming process. The copper ban during the Spring and Autumn period in China was the earliest known lost wax casting method. The first step is to make a mold, using the mold to inject liquid wax into the mold to form a wax mold. Then, the wax mold is pasted into a pouring system according to the casting process, and the entire pouring system is made into a silica sol shell. After dewaxing, the entire shell becomes a cavity, and the cavity shell can be poured with molten steel after calcination. After cooling, the steel material product is formed. Subsequently, through processes such as cutting and grinding, sandblasting, heat treatment, correction, welding repair, electroplating, and machining, the cast products required by the customer are formed.

2024/10/08

Dalian is a beautiful coastal city in Northeast China, with beautiful scenery and pleasant climate. It is an important industrial production base, an international shipping center in Northeast Asia.

2024/07/11

Dalian Sakabe has own foundry factory and focus on providing high-quality precision casting products to domestic and foreign customers since its establishment in 2005.

2024/10/08

The Crucial Role of Casting Material Trays in Advanced Manufacturing

In the ever-evolving landscape of manufacturing, optimizing heat treatment processes through the strategic use of casting material trays is paramount

2025/09/19