Why Quality Beverage Machinery Parts Casting is Essential for Optimal Production Efficiency

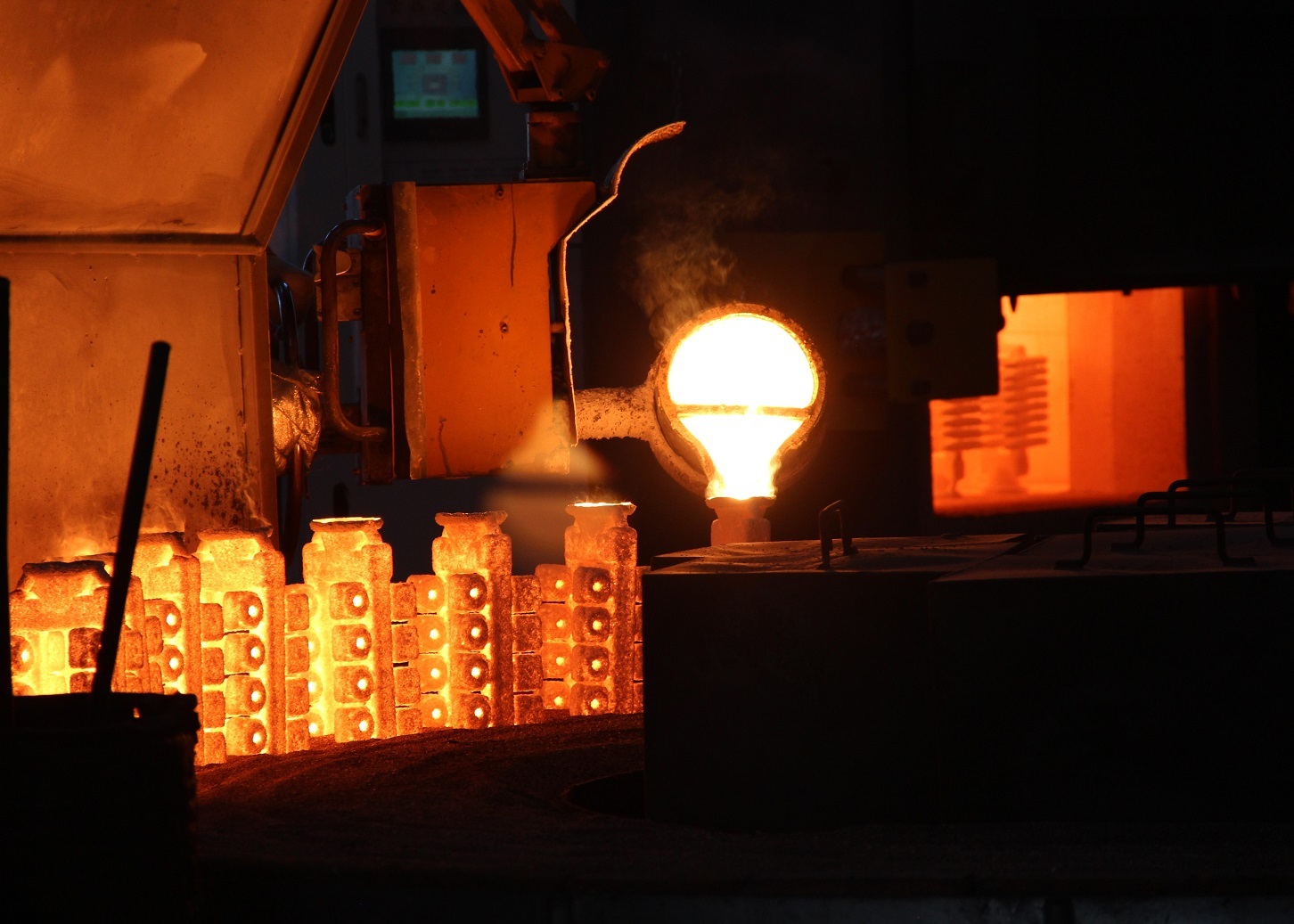

In the beverage manufacturing sector, the performance and durability of machinery are paramount factors that can significantly influence production efficiency and product quality. One of the key elements that underpin these attributes is the use of quality beverage machinery parts casting. Casting, a process where liquid material is poured into a mold to solidify, plays a vital role in creating components that are both robust and precise.

The casting process for beverage machinery parts typically involves various materials, including aluminum, iron, and steel. Each material possesses unique properties that can be advantageous depending on the specific application. For instance, aluminum castings are often favored for their lightweight nature and resistance to corrosion, making them suitable for components exposed to various liquids. On the other hand, iron and steel castings provide exceptional strength and durability, essential for parts that undergo significant wear and tear during operation.

Quality beverage machinery parts casting not only ensures that the machinery functions smoothly but also contributes to the overall safety of the production environment. Well-cast components reduce the risk of mechanical failures, which can lead to costly downtime and safety hazards for workers. Therefore, investing time and resources into high-quality casting processes is beneficial for manufacturers looking to maintain operational efficiency and uphold safety standards.

Moreover, the precision achieved through quality casting can directly impact the performance of beverage machinery. Components that are manufactured with accuracy reduce the likelihood of misalignments and mechanical inefficiencies, which can lead to subpar product quality. This is particularly crucial in the beverage industry, where consistency is key to maintaining brand reputation and meeting regulatory standards.

Sourcing quality beverage machinery parts casting also involves considering the expertise of the foundry and the technology they employ. Advanced casting techniques, such as investment casting or sand casting, can enhance the quality of the final product. Additionally, collaborating with experienced suppliers who understand the specific needs of the beverage machinery sector can ensure that the components produced meet both industry standards and customer expectations.

In conclusion, the importance of quality beverage machinery parts casting cannot be overstated in the manufacturing process. By focusing on high-quality casting practices, manufacturers can improve equipment performance, enhance product quality, and foster a safer working environment. Investing in the right materials and processes ultimately leads to a more efficient production line, benefiting both manufacturers and consumers alike.

Development prospects of investment casting

The products obtained by investment casting are precise and complex, close to the final shape of the parts, and can be directly used without or with little machining. It is an advanced technology for near net formation and an excellent process technology in the casting industry, with a wide range of applications. It is suitable for casting various types of alloys, and the produced castings have higher dimensional accuracy and surface quality than other casting methods. Even complex, high-temperature resistant, and difficult to process castings can be cast using investment casting precision casting.

2024/10/08