In the manufacturing and machining industry, especially within the realms of metal casting and forging, the importance of customized tooling casting for heat treatment furnaces cannot be overstated. Heat treatment processes are crucial for enhancing the mechanical properties of various materials, and the efficiency of these processes often hinges on the quality and adaptability of the tooling used.

Customized tooling casting involves creating tooling that is tailored specifically to the requirements of a particular heat treatment process. This can include molds, dies, and other components that are designed to withstand high temperatures and harsh environmental conditions encountered during heat treatment. The advantage of such tailored solutions is that they can significantly improve the efficiency and effectiveness of the heat treatment process, leading to better material performance and increased production rates.

One of the key benefits of customized tooling casting for heat treatment furnaces is the ability to optimize thermal conductivity and heat retention. The right tooling can enhance the heat distribution within the furnace, ensuring that materials are treated evenly. This uniformity is essential in achieving consistent mechanical properties in the final product, reducing the occurrence of defects and failures.

Moreover, customized tooling can also contribute to cost-effectiveness. By designing tooling that is specifically suited for the intended application, manufacturers can minimize waste and maximize resource utilization. This not only reduces production costs but also lowers the environmental impact associated with excess material use and energy consumption.

Another aspect to consider is the adaptability of customized tooling. As manufacturing processes evolve, so too do the demands placed on heat treatment furnaces. Custom tooling can be designed to accommodate various materials and treatment processes, allowing manufacturers to remain agile and responsive to changing market requirements.

Additionally, collaboration with experienced foundries that specialize in customized tooling casting can lead to the development of innovative solutions. These experts understand the intricacies of heat treatment processes and can offer insights into the best materials and designs for tooling that will meet specific operational challenges.

In conclusion, customized tooling casting plays a vital role in the performance and efficiency of heat treatment furnaces. By investing in tailored tooling solutions, manufacturers can enhance their operational capabilities, improve product quality, and achieve greater overall efficiency in their heat treatment processes. Whether through improved thermal management or increased adaptability, the benefits of customized tooling are significant and can lead to substantial advancements in manufacturing outcomes.

Customized tooling casting involves creating tooling that is tailored specifically to the requirements of a particular heat treatment process. This can include molds, dies, and other components that are designed to withstand high temperatures and harsh environmental conditions encountered during heat treatment. The advantage of such tailored solutions is that they can significantly improve the efficiency and effectiveness of the heat treatment process, leading to better material performance and increased production rates.

One of the key benefits of customized tooling casting for heat treatment furnaces is the ability to optimize thermal conductivity and heat retention. The right tooling can enhance the heat distribution within the furnace, ensuring that materials are treated evenly. This uniformity is essential in achieving consistent mechanical properties in the final product, reducing the occurrence of defects and failures.

Moreover, customized tooling can also contribute to cost-effectiveness. By designing tooling that is specifically suited for the intended application, manufacturers can minimize waste and maximize resource utilization. This not only reduces production costs but also lowers the environmental impact associated with excess material use and energy consumption.

Another aspect to consider is the adaptability of customized tooling. As manufacturing processes evolve, so too do the demands placed on heat treatment furnaces. Custom tooling can be designed to accommodate various materials and treatment processes, allowing manufacturers to remain agile and responsive to changing market requirements.

Additionally, collaboration with experienced foundries that specialize in customized tooling casting can lead to the development of innovative solutions. These experts understand the intricacies of heat treatment processes and can offer insights into the best materials and designs for tooling that will meet specific operational challenges.

In conclusion, customized tooling casting plays a vital role in the performance and efficiency of heat treatment furnaces. By investing in tailored tooling solutions, manufacturers can enhance their operational capabilities, improve product quality, and achieve greater overall efficiency in their heat treatment processes. Whether through improved thermal management or increased adaptability, the benefits of customized tooling are significant and can lead to substantial advancements in manufacturing outcomes.

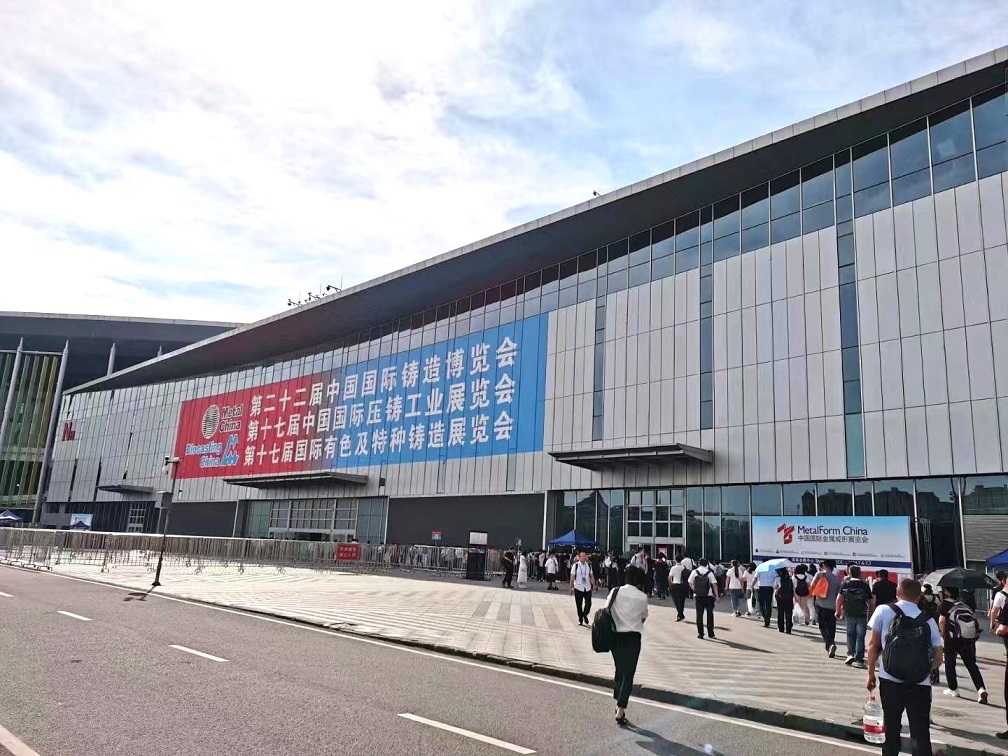

2024 Shanghai International Foundry Expo

In December 2024, Dalian Sakabe met new friends at the Shanghai International Foundry Expo

2024/12/30

Sakabe production exchange meeting between Chinese and Japanese teams

A stable international cooperation relationships are particularly precious in the increasingly severe international environment. Sakabe production teams from China and Japan held a production exchange meeting recently.

2024/10/08

2024/10/08