In the ever-evolving landscape of manufacturing and mechanical processing, new dewax casting emerges as a significant innovation, particularly in the realm of medical equipment parts. This advanced technique involves a meticulous process of creating high-quality metal components that are crucial for medical devices, ensuring they meet stringent standards for safety and reliability.

Dewax casting, also known as lost-wax casting, is a traditional method that has been refined over time. The process begins with the creation of a wax model, which is then coated in a ceramic shell. Once the shell is formed, the wax is melted and removed, leaving a cavity that is filled with molten metal. This results in highly accurate and intricate components that are essential in medical applications.

One of the primary advantages of new dewax casting is its ability to produce complex geometries that would be challenging or impossible to achieve through conventional methods. In medical equipment, where precision is paramount, this capability allows for the design of components that enhance the functionality and performance of devices. For instance, intricate designs can lead to weight reductions and improve the overall ergonomics of surgical instruments and implants.

Moreover, the new dewax casting process boasts improved material properties, ensuring that the parts produced are not only lightweight but also durable and resistant to corrosion. This is particularly important for medical equipment, which must withstand harsh sterilization processes and operate efficiently over extended periods. The enhanced mechanical properties often translate to longer service life, reducing the need for frequent replacements.

Another notable benefit is the efficiency of production. With new dewax casting, manufacturers can achieve faster turnaround times without compromising quality. This efficiency is crucial in the medical field, where the demand for reliable medical equipment is ever-increasing. The ability to quickly produce high-quality parts helps in meeting tight deadlines and responding to urgent healthcare needs.

Furthermore, as the healthcare industry continues to embrace advancements in technology, the integration of new dewax casting processes aligns with the push for more sustainable manufacturing practices. This method typically generates less waste compared to traditional casting processes, making it a more environmentally friendly option.

In conclusion, the development of new dewax casting techniques for medical equipment parts represents a significant leap forward in manufacturing technology. By providing solutions that prioritize precision, durability, and efficiency, this innovative approach is poised to play a critical role in shaping the future of medical devices, ultimately benefiting patients and healthcare providers alike. Understanding these advancements will position stakeholders to better navigate the complexities of the medical manufacturing landscape.

Dewax casting, also known as lost-wax casting, is a traditional method that has been refined over time. The process begins with the creation of a wax model, which is then coated in a ceramic shell. Once the shell is formed, the wax is melted and removed, leaving a cavity that is filled with molten metal. This results in highly accurate and intricate components that are essential in medical applications.

One of the primary advantages of new dewax casting is its ability to produce complex geometries that would be challenging or impossible to achieve through conventional methods. In medical equipment, where precision is paramount, this capability allows for the design of components that enhance the functionality and performance of devices. For instance, intricate designs can lead to weight reductions and improve the overall ergonomics of surgical instruments and implants.

Moreover, the new dewax casting process boasts improved material properties, ensuring that the parts produced are not only lightweight but also durable and resistant to corrosion. This is particularly important for medical equipment, which must withstand harsh sterilization processes and operate efficiently over extended periods. The enhanced mechanical properties often translate to longer service life, reducing the need for frequent replacements.

Another notable benefit is the efficiency of production. With new dewax casting, manufacturers can achieve faster turnaround times without compromising quality. This efficiency is crucial in the medical field, where the demand for reliable medical equipment is ever-increasing. The ability to quickly produce high-quality parts helps in meeting tight deadlines and responding to urgent healthcare needs.

Furthermore, as the healthcare industry continues to embrace advancements in technology, the integration of new dewax casting processes aligns with the push for more sustainable manufacturing practices. This method typically generates less waste compared to traditional casting processes, making it a more environmentally friendly option.

In conclusion, the development of new dewax casting techniques for medical equipment parts represents a significant leap forward in manufacturing technology. By providing solutions that prioritize precision, durability, and efficiency, this innovative approach is poised to play a critical role in shaping the future of medical devices, ultimately benefiting patients and healthcare providers alike. Understanding these advancements will position stakeholders to better navigate the complexities of the medical manufacturing landscape.

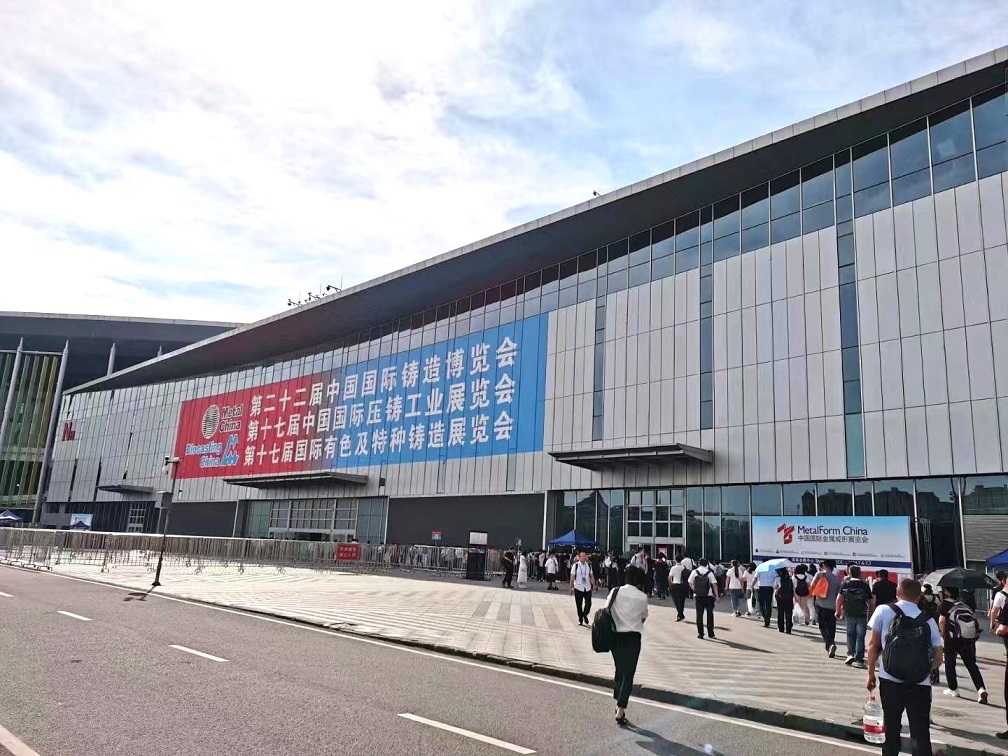

2024 Shanghai International Foundry Expo

In December 2024, Dalian Sakabe met new friends at the Shanghai International Foundry Expo

2024/12/30

Sakabe production exchange meeting between Chinese and Japanese teams

A stable international cooperation relationships are particularly precious in the increasingly severe international environment. Sakabe production teams from China and Japan held a production exchange meeting recently.

2024/10/08

2024/10/08