How Do Medical Equipment Casting Parts Ensure Precision and Reliability in Healthcare Manufacturing

In the realm of manufacturing, particularly within the sector of mechanical hardware processing, the significance of casting parts for medical equipment cannot be overstated. These components play a crucial role in ensuring the durability, functionality, and safety of various medical devices and apparatus. Understanding the intricacies involved in the production of medical equipment casting parts is essential for professionals aiming to maintain high standards in their manufacturing processes.

One of the primary advantages of using casting techniques for medical equipment components is the versatility they offer. Casting allows for the creation of complex shapes and designs that might be challenging to achieve through other manufacturing methods. This is particularly important in the medical field, where equipment often requires precision and intricate details to function effectively. Whether it’s housing for diagnostic machines or structural supports for surgical instruments, casting provides the flexibility needed to meet specific design requirements.

Additionally, the choice of materials used in casting parts for medical equipment is paramount. Common materials include aluminum, stainless steel, and various alloys, each offering distinct benefits. For example, aluminum is favored for its lightweight properties, while stainless steel is prized for its corrosion resistance and strength. When selecting materials, manufacturers must consider factors such as biocompatibility, mechanical properties, and the specific demands of the medical applications involved.

Quality control is another critical aspect of producing medical equipment casting parts. Given the stringent regulations in the medical industry, it is vital to implement rigorous testing and inspection protocols throughout the manufacturing process. This includes evaluating the integrity of the cast parts, ensuring they meet dimensional specifications, and verifying that they can withstand the operational stresses they will encounter during use.

In addition to quality and material considerations, manufacturers must also stay abreast of technological advancements in the casting industry. Innovations such as 3D printing and advanced alloy compositions are reshaping how casting parts are produced. Embracing these technologies can lead to increased efficiency, reduced waste, and improved overall product quality, which are essential factors in the competitive landscape of medical equipment manufacturing.

The production of medical equipment casting parts is a multifaceted process that requires careful consideration of design, materials, and quality assurance. For industry professionals, understanding these elements is crucial in delivering high-quality, reliable medical devices that can significantly impact patient care and outcomes. By focusing on innovative casting techniques and maintaining stringent standards, manufacturers can enhance their contributions to the medical field and ensure the continued advancement of healthcare technology.

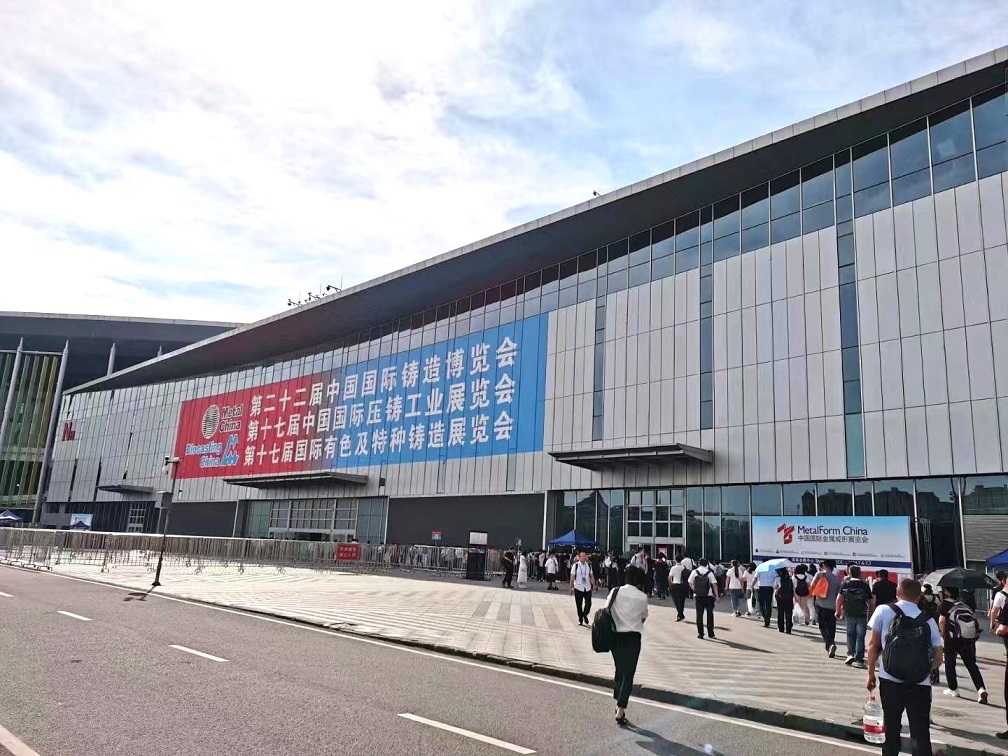

2024 Shanghai International Foundry Expo

In December 2024, Dalian Sakabe met new friends at the Shanghai International Foundry Expo

2024/12/30

Sakabe production exchange meeting between Chinese and Japanese teams

A stable international cooperation relationships are particularly precious in the increasingly severe international environment. Sakabe production teams from China and Japan held a production exchange meeting recently.

2024/10/08

2024/10/08