Heat treatment is a vital process in the field of manufacturing, particularly within the realm of tool casting. This controlled process involves heating and cooling metal to alter its physical and sometimes chemical properties, with the primary goal of enhancing performance and durability. For professionals in the manufacturing and metalworking industries, understanding heat treatment is essential for optimizing tool performance and longevity.

In tool casting, heat treatment can significantly influence the hardness, tensile strength, and wear resistance of the final product. The process typically involves several stages, including heating the material to a specific temperature, holding it at that temperature for a designated period, and then cooling it down at a controlled rate. Each stage must be carefully monitored to achieve the desired properties.

One of the most common heat treatment techniques used in tool casting is quenching, where the heated metal is rapidly cooled, often in water or oil. This process transforms the microstructure of the metal, resulting in increased hardness and strength. However, rapid cooling can also introduce stresses within the material, leading to potential warping or cracking, which is why tempering is often performed afterward. Tempering involves reheating the metal to a lower temperature and then cooling it again, allowing for stress relief while maintaining essential hardness.

Another important method is annealing, which involves heating the metal to a high temperature and then allowing it to cool slowly. This process softens the metal, making it more ductile and easier to work with. For tool casting, this can be particularly advantageous when intricate shapes are involved, as the material's improved ductility can lead to fewer defects during machining or finishing processes.

Heat treatment also plays a pivotal role in ensuring the tool's resistance to wear and corrosion, especially in high-stress applications. The correct heat treatment can enhance the surface properties of the tool, thereby extending its usable life and reducing the frequency of replacements.

In summary, heat treatment in tool casting is a complex but essential process that significantly influences the performance characteristics of cast tools. By carefully selecting the appropriate heat treatment techniques, manufacturers can produce tools that not only meet but exceed the demands of various industrial applications. Understanding the science behind heat treatment enables professionals to make informed decisions and ultimately improves the quality and efficiency of the manufacturing process.

In tool casting, heat treatment can significantly influence the hardness, tensile strength, and wear resistance of the final product. The process typically involves several stages, including heating the material to a specific temperature, holding it at that temperature for a designated period, and then cooling it down at a controlled rate. Each stage must be carefully monitored to achieve the desired properties.

One of the most common heat treatment techniques used in tool casting is quenching, where the heated metal is rapidly cooled, often in water or oil. This process transforms the microstructure of the metal, resulting in increased hardness and strength. However, rapid cooling can also introduce stresses within the material, leading to potential warping or cracking, which is why tempering is often performed afterward. Tempering involves reheating the metal to a lower temperature and then cooling it again, allowing for stress relief while maintaining essential hardness.

Another important method is annealing, which involves heating the metal to a high temperature and then allowing it to cool slowly. This process softens the metal, making it more ductile and easier to work with. For tool casting, this can be particularly advantageous when intricate shapes are involved, as the material's improved ductility can lead to fewer defects during machining or finishing processes.

Heat treatment also plays a pivotal role in ensuring the tool's resistance to wear and corrosion, especially in high-stress applications. The correct heat treatment can enhance the surface properties of the tool, thereby extending its usable life and reducing the frequency of replacements.

In summary, heat treatment in tool casting is a complex but essential process that significantly influences the performance characteristics of cast tools. By carefully selecting the appropriate heat treatment techniques, manufacturers can produce tools that not only meet but exceed the demands of various industrial applications. Understanding the science behind heat treatment enables professionals to make informed decisions and ultimately improves the quality and efficiency of the manufacturing process.

Development prospects of investment casting

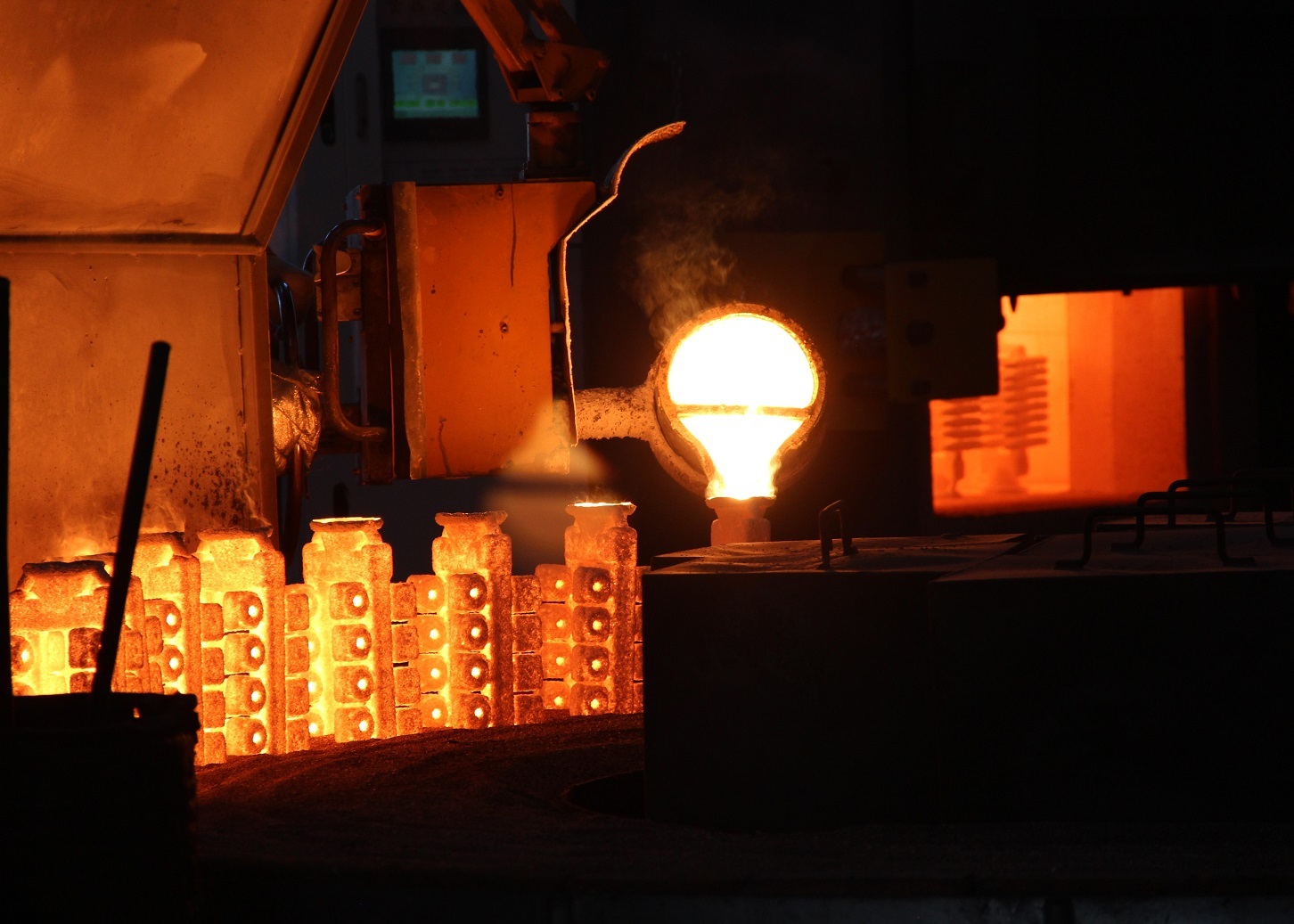

The products obtained by investment casting are precise and complex, close to the final shape of the parts, and can be directly used without or with little machining. It is an advanced technology for near net formation and an excellent process technology in the casting industry, with a wide range of applications. It is suitable for casting various types of alloys, and the produced castings have higher dimensional accuracy and surface quality than other casting methods. Even complex, high-temperature resistant, and difficult to process castings can be cast using investment casting precision casting.

2024/10/08