In the manufacturing and processing industry, particularly within the realm of beverage production, the quality and durability of machinery play a crucial role in efficiency and output. One of the essential components contributing to this durability is the casting parts used in beverage machinery. Durable beverage machinery casting parts are designed to withstand the rigorous demands of processing and handling various beverages, ensuring long-lasting performance and reliability.

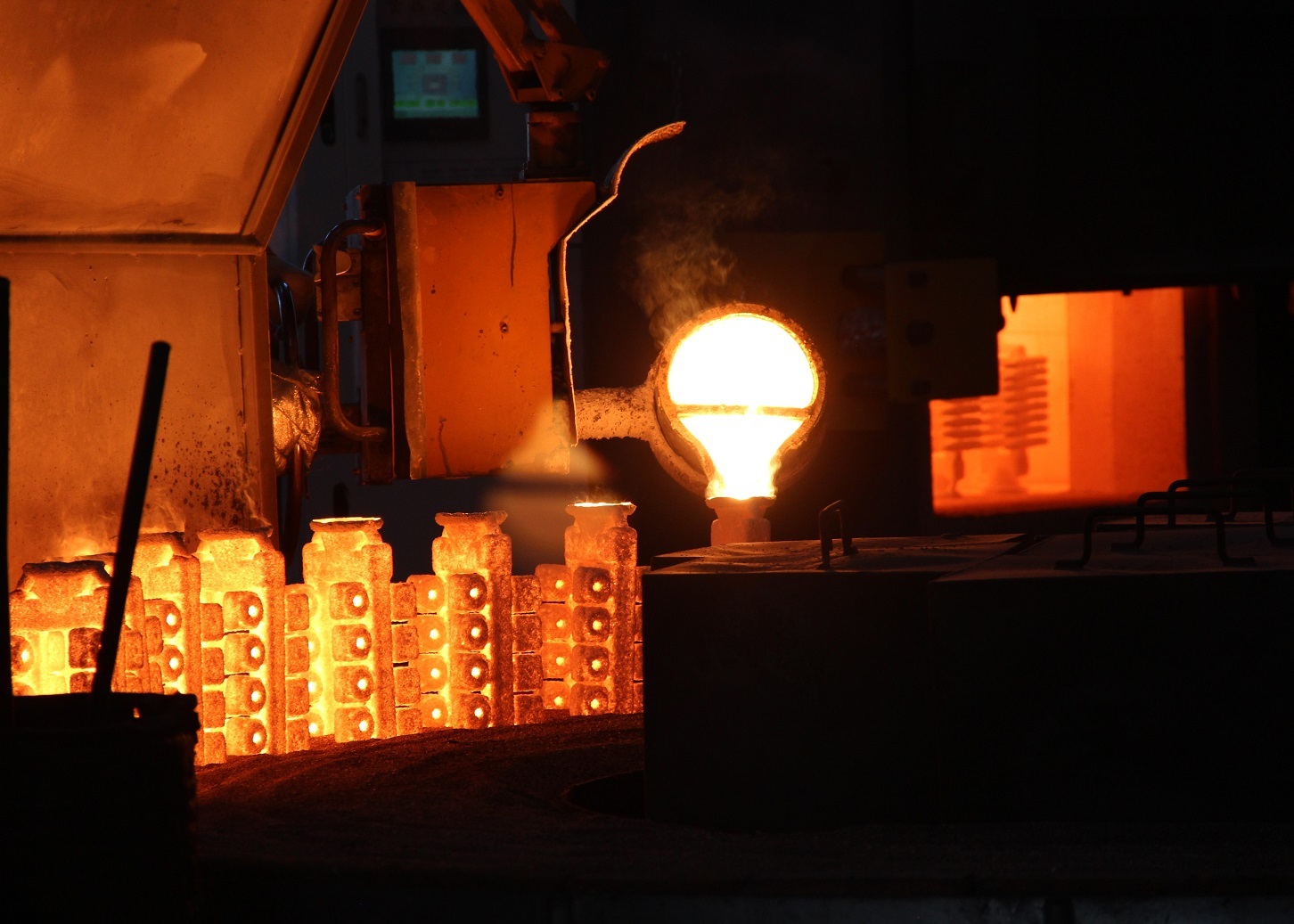

Casting is a method employed to create parts from molten material, usually metal, which is poured into molds to solidify. This technique allows for intricate designs and shapes that are essential for the complex machinery involved in beverage production. The durability of casting parts is paramount, as these components are often exposed to high pressures, temperatures, and corrosive substances. Therefore, selecting the appropriate materials for these casting parts is critical.

Common materials used for durable beverage machinery casting parts include stainless steel, aluminum, and ductile iron. Stainless steel is favored for its corrosion resistance and strength, making it ideal for machinery that handles acidic or carbonated beverages. Aluminum castings are lightweight and have excellent thermal conductivity, which is beneficial in applications where heat dissipation is necessary. Ductile iron, known for its toughness and ability to absorb shock, is often utilized in heavy-duty machinery components that require both strength and flexibility.

In addition to material selection, the manufacturing process of casting parts significantly impacts their durability. Processes such as sand casting, investment casting, and die casting each have unique advantages that can enhance the quality of the final product. For instance, investment casting is ideal for intricate designs and provides a smooth finish, whereas sand casting is more versatile and cost-effective for larger parts.

The application of durable beverage machinery casting parts extends beyond just creating machines. It also encompasses the maintenance and operational efficiency of these machines. Well-made casting parts reduce the likelihood of breakdowns, minimize the need for frequent replacements, and ultimately lead to lower operational costs. For businesses in the beverage industry, investing in high-quality casting parts can translate into increased productivity and enhanced product quality.

In conclusion, durable beverage machinery casting parts are vital for ensuring the longevity and efficiency of machinery involved in beverage production. By understanding the materials, processes, and applications associated with these casting parts, manufacturers can make informed decisions that lead to better performance and greater success in the competitive beverage market. Investing in durable components not only improves machinery resilience but also contributes to the overall effectiveness of production operations, ensuring that businesses can meet consumer demands with reliability and confidence.

Casting is a method employed to create parts from molten material, usually metal, which is poured into molds to solidify. This technique allows for intricate designs and shapes that are essential for the complex machinery involved in beverage production. The durability of casting parts is paramount, as these components are often exposed to high pressures, temperatures, and corrosive substances. Therefore, selecting the appropriate materials for these casting parts is critical.

Common materials used for durable beverage machinery casting parts include stainless steel, aluminum, and ductile iron. Stainless steel is favored for its corrosion resistance and strength, making it ideal for machinery that handles acidic or carbonated beverages. Aluminum castings are lightweight and have excellent thermal conductivity, which is beneficial in applications where heat dissipation is necessary. Ductile iron, known for its toughness and ability to absorb shock, is often utilized in heavy-duty machinery components that require both strength and flexibility.

In addition to material selection, the manufacturing process of casting parts significantly impacts their durability. Processes such as sand casting, investment casting, and die casting each have unique advantages that can enhance the quality of the final product. For instance, investment casting is ideal for intricate designs and provides a smooth finish, whereas sand casting is more versatile and cost-effective for larger parts.

The application of durable beverage machinery casting parts extends beyond just creating machines. It also encompasses the maintenance and operational efficiency of these machines. Well-made casting parts reduce the likelihood of breakdowns, minimize the need for frequent replacements, and ultimately lead to lower operational costs. For businesses in the beverage industry, investing in high-quality casting parts can translate into increased productivity and enhanced product quality.

In conclusion, durable beverage machinery casting parts are vital for ensuring the longevity and efficiency of machinery involved in beverage production. By understanding the materials, processes, and applications associated with these casting parts, manufacturers can make informed decisions that lead to better performance and greater success in the competitive beverage market. Investing in durable components not only improves machinery resilience but also contributes to the overall effectiveness of production operations, ensuring that businesses can meet consumer demands with reliability and confidence.

Development prospects of investment casting

The products obtained by investment casting are precise and complex, close to the final shape of the parts, and can be directly used without or with little machining. It is an advanced technology for near net formation and an excellent process technology in the casting industry, with a wide range of applications. It is suitable for casting various types of alloys, and the produced castings have higher dimensional accuracy and surface quality than other casting methods. Even complex, high-temperature resistant, and difficult to process castings can be cast using investment casting precision casting.

2024/10/08