---

In the manufacturing industry, particularly in the realm of mechanical hardware processing, the use of wholesale die-casting parts for sewing machines plays a crucial role. Die casting is a manufacturing process that involves forcing molten metal into a mold. This method is particularly advantageous for producing complex shapes with high precision, making it ideal for parts used in sewing machines.

Wholesale die-casting parts typically consist of aluminum, zinc, and magnesium alloys. These materials are favored for their lightweight properties and resistance to corrosion, which enhances the longevity of the parts. In sewing machines, these components can include everything from structural frames to intricate mechanism parts that enable smooth operation and functionality. The durability of die-cast parts ensures that sewing machines can operate at optimal performance levels for extended periods, minimizing downtime for repairs and enhancing overall productivity.

The die-casting process begins with the preparation of the mold, which is designed to the exact specifications of the part being produced. Once the mold is ready, molten metal is injected at high pressure, filling the cavity and taking the shape of the mold. After cooling, the mold is opened, and the newly formed part is ejected. This method not only speeds up production but also allows for consistent quality across large batches—ideal for businesses looking to purchase wholesale.

Moreover, the use of wholesale die-casting parts can lead to significant cost savings. By purchasing in bulk, manufacturers can reduce per-unit costs, allowing for more competitive pricing in the market. Additionally, process efficiency means that less material waste is generated, promoting a more sustainable approach to manufacturing.

When considering wholesale die-casting parts for sewing machines, it is essential to focus on the quality and specifications of the parts. High-quality die-casting can result in tighter tolerances, better surface finishes, and improved overall performance. Therefore, sourcing from reputable suppliers who adhere to stringent quality control processes is vital.

In summary, wholesale die-casting parts are a cornerstone of the sewing machine manufacturing process. Their ability to provide high precision, durability, and cost-effectiveness makes them an excellent choice for businesses in the mechanical hardware industry. By understanding the benefits of these components, manufacturers can improve their production capabilities and maintain a competitive edge in the market.

In the manufacturing industry, particularly in the realm of mechanical hardware processing, the use of wholesale die-casting parts for sewing machines plays a crucial role. Die casting is a manufacturing process that involves forcing molten metal into a mold. This method is particularly advantageous for producing complex shapes with high precision, making it ideal for parts used in sewing machines.

Wholesale die-casting parts typically consist of aluminum, zinc, and magnesium alloys. These materials are favored for their lightweight properties and resistance to corrosion, which enhances the longevity of the parts. In sewing machines, these components can include everything from structural frames to intricate mechanism parts that enable smooth operation and functionality. The durability of die-cast parts ensures that sewing machines can operate at optimal performance levels for extended periods, minimizing downtime for repairs and enhancing overall productivity.

The die-casting process begins with the preparation of the mold, which is designed to the exact specifications of the part being produced. Once the mold is ready, molten metal is injected at high pressure, filling the cavity and taking the shape of the mold. After cooling, the mold is opened, and the newly formed part is ejected. This method not only speeds up production but also allows for consistent quality across large batches—ideal for businesses looking to purchase wholesale.

Moreover, the use of wholesale die-casting parts can lead to significant cost savings. By purchasing in bulk, manufacturers can reduce per-unit costs, allowing for more competitive pricing in the market. Additionally, process efficiency means that less material waste is generated, promoting a more sustainable approach to manufacturing.

When considering wholesale die-casting parts for sewing machines, it is essential to focus on the quality and specifications of the parts. High-quality die-casting can result in tighter tolerances, better surface finishes, and improved overall performance. Therefore, sourcing from reputable suppliers who adhere to stringent quality control processes is vital.

In summary, wholesale die-casting parts are a cornerstone of the sewing machine manufacturing process. Their ability to provide high precision, durability, and cost-effectiveness makes them an excellent choice for businesses in the mechanical hardware industry. By understanding the benefits of these components, manufacturers can improve their production capabilities and maintain a competitive edge in the market.

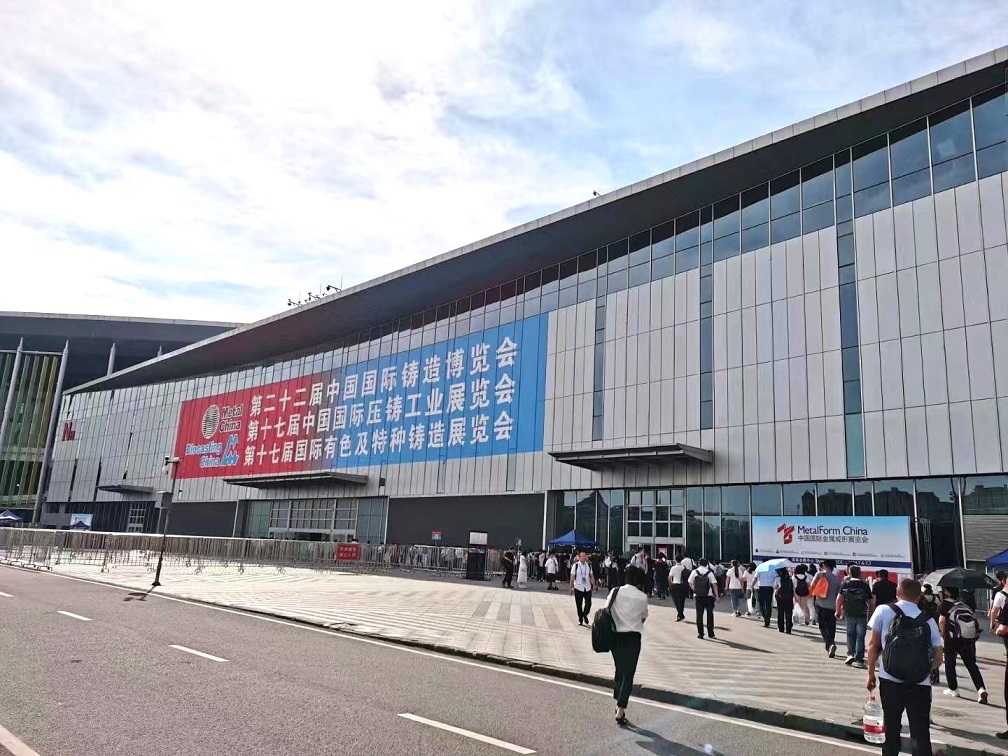

2024 Shanghai International Foundry Expo

In December 2024, Dalian Sakabe met new friends at the Shanghai International Foundry Expo

2024/12/30

Sakabe production exchange meeting between Chinese and Japanese teams

A stable international cooperation relationships are particularly precious in the increasingly severe international environment. Sakabe production teams from China and Japan held a production exchange meeting recently.

2024/10/08

2024/10/08