Unlocking the Benefits of Chinese Precision Casting for Heat Treatment

Chinese precision casting has emerged as a pivotal technique in the manufacturing and mechanical engineering sectors, particularly for components subjected to heat treatment processes. This method, known for its ability to produce complex shapes with high dimensional accuracy, is particularly beneficial for industries that rely on durable and efficient components.

At its core, precision casting involves the creation of a mold into which molten metal is poured. The precision aspect comes from the meticulous control over the entire casting process, including temperature, material composition, and mold design. This level of control results in castings that not only meet stringent specifications but also maintain a high degree of consistency and reliability.

One of the primary benefits of using Chinese precision casting in heat treatment is the improved mechanical properties of the final product. Heat treatment processes, such as quenching and tempering, are crucial for enhancing the strength, toughness, and wear resistance of metals. When precision cast components undergo these processes, they exhibit significantly better performance in demanding applications compared to traditional casting methods. The uniformity in the microstructure achieved through precision casting facilitates optimal heat treatment outcomes, leading to longer-lasting components.

Moreover, the intricate designs achievable through precision casting allow for the production of lightweight yet robust parts, which is essential in industries like aerospace and automotive manufacturing. By minimizing excess material while maintaining structural integrity, manufacturers can reduce overall production costs and improve energy efficiency in the final product.

The flexibility of precision casting also plays a key role in its effectiveness for heat treatment purposes. Manufacturers can tailor the material properties to meet specific requirements, such as corrosion resistance or thermal stability, depending on the application. This customization capability not only enhances the performance of the components but also opens up new possibilities for innovation in product design.

In addition to these benefits, Chinese precision casting contributes to significant time savings in the production cycle. The reduced need for machining after casting means that components can be produced more quickly and with less waste, fostering a more sustainable manufacturing process. This efficiency is particularly crucial in today’s fast-paced industrial landscape, where time-to-market is often a critical factor in maintaining competitiveness.

In summary, Chinese precision casting for heat treatment presents numerous advantages, including improved mechanical properties, design flexibility, and production efficiency. As industries continue to demand higher quality and more innovative components, embracing precision casting techniques will be essential for staying ahead in the competitive landscape of manufacturing and mechanical engineering.

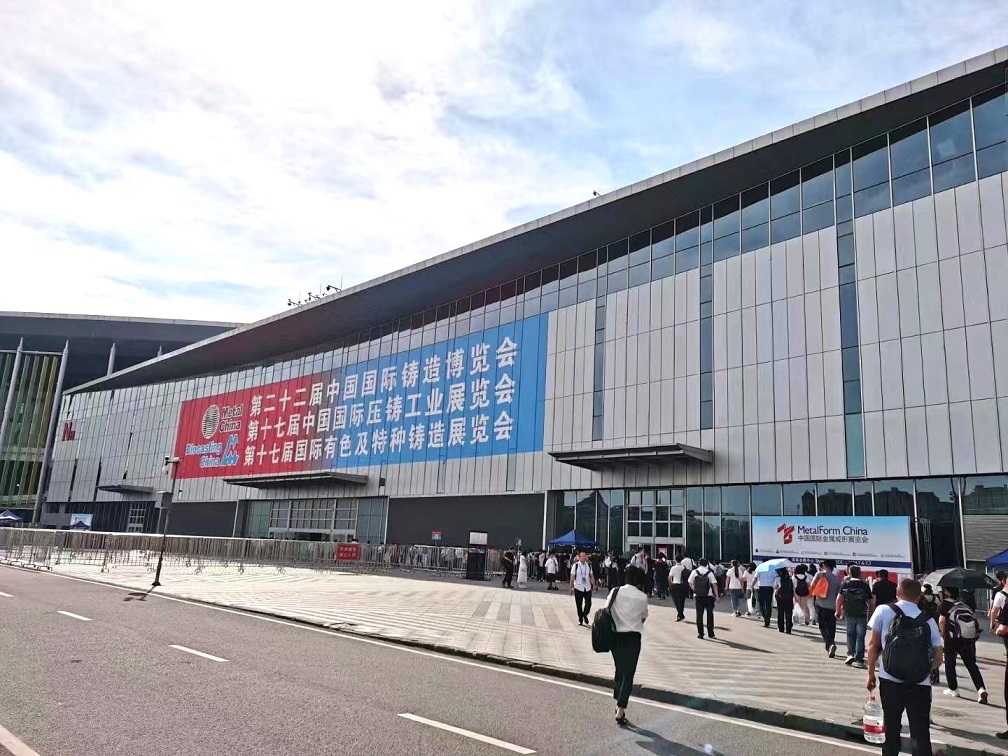

2024 Shanghai International Foundry Expo

In December 2024, Dalian Sakabe met new friends at the Shanghai International Foundry Expo

2024/12/30

Sakabe production exchange meeting between Chinese and Japanese teams

A stable international cooperation relationships are particularly precious in the increasingly severe international environment. Sakabe production teams from China and Japan held a production exchange meeting recently.

2024/10/08

2024/10/08