Heat Treatment Tool Material Tray Frame Design: Best Practices for Efficiency

Introduction to Heat Treatment Tool Material Tray Frames

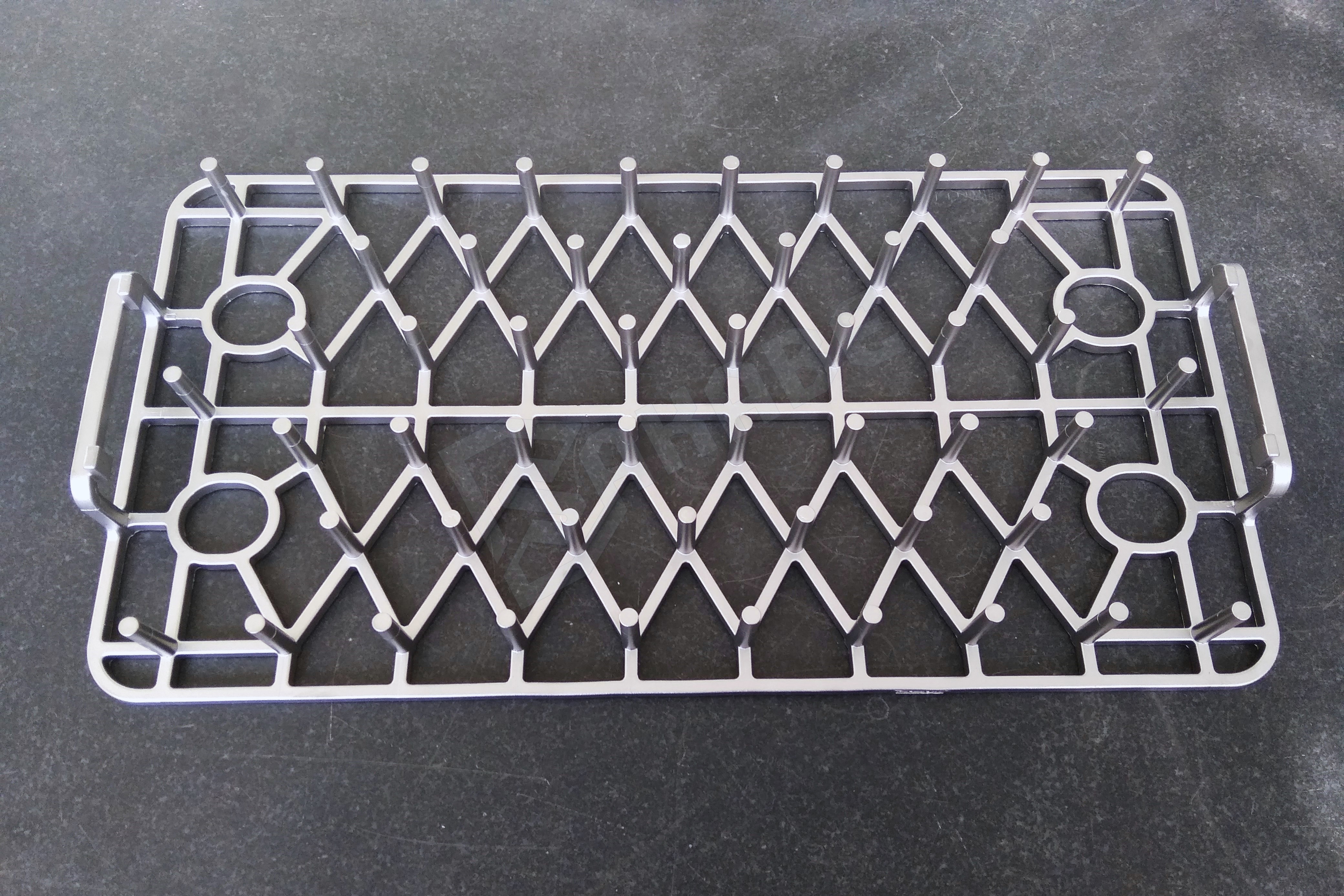

Heat treatment is a pivotal process in the manufacturing industry, affecting the mechanical properties of materials by altering their microstructure. Among the various components involved in this process, **heat treatment tool material tray frames** play a crucial role in ensuring the efficient and safe handling of components during treatment. This article aims to explore the best practices for designing these frames, focusing on enhancing efficiency, durability, and functionality.

Importance of Effective Tray Frame Design

Effective tray frame design is essential for several reasons:

1. **Maximizing Space Utilization**: Properly designed trays can lead to more efficient use of furnace space, allowing for larger batches and reduced energy costs.

2. **Preventing Damage**: A well-thought-out design minimizes the risk of damaging components during transportation or heat treatment.

3. **Improving Heat Distribution**: The design of the tray frame affects how heat circulates around the components, impacting the overall quality of the heat treatment process.

By understanding the importance of these factors, manufacturers can optimize their processes and achieve superior results.

Key Elements of an Efficient Tray Frame Design

When designing a heat treatment tool material tray frame, several key elements should be considered:

Material Selection

The material used for the frame must withstand high temperatures and corrosive environments without deforming or degrading. Common materials include stainless steel, Inconel, and other high-temperature alloys.

Load Capacity

The frame must support the weight of the components being treated. Proper calculations should ensure that the tray can handle maximum load without bending or breaking.

Size and Dimensions

Frames should be designed to fit perfectly within the heat treatment equipment while allowing for sufficient airflow around components to facilitate even heating.

Modularity

Incorporating a modular design allows for easy customization and adaptability to different sizes and shapes of components, enhancing usability.

Ease of Handling

Frames should include features such as handles or attachment points for lifting equipment to facilitate safe handling and transportation.

Choosing the Right Materials for Tray Frames

Selecting the appropriate materials for heat treatment tool material tray frames is critical for performance and longevity. Here are some common materials and their advantages:

Stainless Steel

Stainless steel is resistant to corrosion and oxidation, making it a popular choice for heat treatment trays. It can withstand high temperatures and is easy to clean, ensuring hygiene.

High-Temperature Alloys

Alloys like Inconel or nickel-based materials offer excellent heat resistance and mechanical strength. They are ideal for extreme temperature applications.

Refractory Materials

For trays used in more specialized processes, refractory materials can be employed to withstand very high temperatures and thermal shock.

Fundamental Design Principles for Tray Frames

To achieve an efficient tray frame design, several fundamental principles should be followed:

Thermal Conductivity

The design should ensure optimal thermal conductivity to facilitate even heating. This can be achieved through proper spacing and material selection.

Structural Integrity

The frame must be designed to maintain its shape and strength under varying loads and temperatures. Reinforcements should be strategically placed to enhance durability.

Minimizing Contamination

Design features should prevent contamination of components during processing, such as avoiding crevices where debris can accumulate.

Accessibility

Designing trays for easy access simplifies loading and unloading, improving operational efficiency.

Optimizing Heat Treatment Processes with Tray Design

An efficient tray frame design directly impacts the heat treatment process. Here are ways to optimize performance:

Improved Airflow

Frames should be designed to enhance airflow around components, promoting uniform heating and improving treatment outcomes.

Batch Processing

Designing trays for batch processing allows for simultaneous treatment of multiple components, saving time and energy.

Integrated Sensors

Incorporating sensors into tray designs can monitor temperatures and conditions, providing data for optimizing treatment cycles.

Common Challenges in Tray Frame Design and Solutions

Designing heat treatment tool material tray frames can present several challenges:

Heat Deformation

**Solution**: Choose materials with high thermal stability and incorporate design features that minimize stress concentrations.

Weight Limitations

**Solution**: Use advanced materials and innovative designs that reduce weight while maintaining strength.

Complex Component Shapes

**Solution**: Implement a modular design that allows for adjustments and adaptations for varying component shapes and sizes.

Case Studies: Successful Tray Frame Implementations

Examining real-world applications can provide insights into effective tray frame designs:

Case Study 1: Automotive Parts Manufacturer

An automotive parts manufacturer redesigned their tray frames to optimize space and airflow, resulting in a 20% reduction in cycle times and improved product quality.

Case Study 2: Aerospace Component Supplier

By utilizing high-temperature alloys and modular design, an aerospace supplier improved its heat treatment process, achieving higher consistency and a 30% increase in output.

Conclusion

Designing efficient heat treatment tool material tray frames is essential for enhancing productivity and ensuring the quality of the heat treatment process. By implementing best practices in material selection, design principles, and optimization techniques, manufacturers can achieve significant improvements in efficiency, durability, and safety. Adopting these best practices will not only streamline operations but also provide a competitive advantage in the ever-evolving industrial landscape.

Dalian Sakabe was invited to participate in the Dalian investment promotion project ceremony

On March 27, 2025, Dalian Sakabe, as an advanced foreign-funded enterprise in Dalian, was invited to participate in the investment promotion project ceremony of Dalian China.

2025/04/01

It is pleased that partner NME come to visit us Sakabe foundry

It is pleased that partner NME come to visit us Sakabe foundry. We share the same philosophy about quality standards, product positioning, environmental protection, and sustainable development. It's lucky to meet like-minded partners!

2025/02/19

Great meeting with partner in Shanghai

Dalian Sakabe paying visit to our partner TST in Shanghai. Had discussions and plans for long term co-operation. Great thanks for your support!

2025/01/02