The Role of Advanced Fluid Chemical Equipment Parts in Modern Manufacturing

The Role of Advanced Fluid Chemical Equipment Parts in Modern Manufacturing

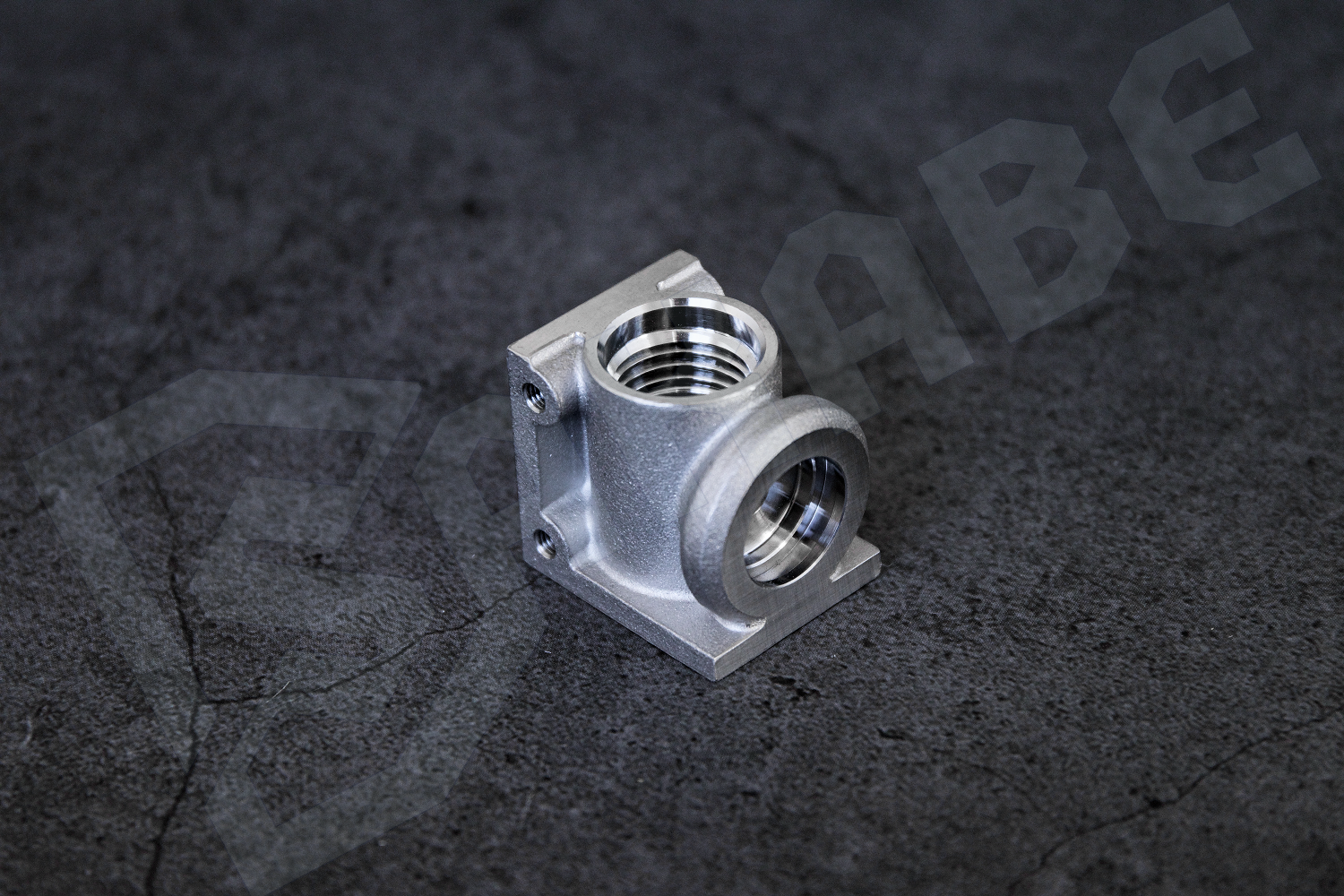

Manufacturing processes have continuously evolved, driven by technological advancements and the need for greater efficiency. In this context, **advanced fluid chemical equipment parts casting** plays a pivotal role in optimizing production workflows, maintaining high quality, and ensuring safety. This article delves into the various facets of these components, their importance, and how they elevate the manufacturing industry.

1. Understanding Advanced Fluid Chemical Equipment Parts

Advanced fluid chemical equipment parts refer to specialized components used in various manufacturing industries to manage, control, and optimize the flow of chemicals in production processes. These parts are critical in ensuring that chemical reactions occur under optimal conditions, thus enhancing the overall efficiency of manufacturing systems. They include essential components such as pumps, valves, and reactors, each designed to perform specific functions that contribute to the fluid handling process.

2. The Importance of Efficiency in Manufacturing

In the competitive landscape of manufacturing, efficiency is crucial. It not only affects the **bottom line** but also influences product quality and operational sustainability. Efficient manufacturing processes result in decreased waste, reduced energy consumption, and improved product turnaround times. As industries strive to deliver products faster and with better quality, the role of fluid chemical equipment parts has become increasingly significant, enabling manufacturers to meet the growing demands of their customers.

3. Key Components of Fluid Chemical Equipment

Understanding the key components of advanced fluid chemical equipment is essential to grasp their impact on manufacturing efficiency.

3.1 Pumps

Pumps are integral in transporting chemicals from one point to another in a manufacturing process. They come in various types, including centrifugal and positive displacement pumps, each suited for specific applications. The selection of the right pump can significantly enhance the efficiency of chemical transfer, minimizing downtime and ensuring a continuous flow.

3.2 Valves

Valves regulate the flow and pressure of fluids within production systems. They can be manual or automated and are essential for controlling the liquid's passage through pipes, ensuring that chemicals are delivered accurately and safely. The use of advanced valve technology allows for better precision in chemical handling, thus improving overall operational efficiency.

3.3 Heat Exchangers

Heat exchangers play a vital role in managing temperature during chemical reactions. They transfer heat between two or more fluids, allowing for efficient temperature control. This component is critical in industries where specific temperature ranges are necessary for optimal chemical reactions, ensuring consistent product quality.

3.4 Reactors

Reactors are vessels where chemical reactions occur. Their design and efficiency directly impact the quality and yield of the final product. Advanced reactor technology enables manufacturers to optimize reaction conditions, thus unlocking higher efficiencies in production.

4. Benefits of Advanced Fluid Chemical Equipment Parts

Implementing advanced fluid chemical equipment parts in manufacturing processes offers numerous benefits.

4.1 Increased Productivity

Automation and advanced design of fluid chemical equipment parts lead to higher productivity. With reduced manual intervention and enhanced operational capabilities, manufacturers can scale production without compromising quality.

4.2 Enhanced Quality Control

Precision is key in manufacturing, especially when handling chemicals. Advanced equipment parts ensure accurate measurements and control, resulting in higher product quality and reduced chances of defects.

4.3 Improved Safety Standards

Safety is paramount in any manufacturing process. Advanced fluid chemical equipment parts are designed with safety features that minimize risks associated with chemical handling. This includes leak detection systems and automated controls that reduce human error, thus creating a safer working environment.

5. Innovations in Fluid Chemical Equipment

The field of fluid chemical equipment is constantly evolving, driven by technological advancements.

5.1 Smart Technology Integration

The integration of smart technology, such as IoT sensors and data analytics, is revolutionizing fluid chemical equipment. These innovations allow for real-time monitoring of processes, predictive maintenance, and optimized performance, leading to significant cost savings and efficiency improvements.

5.2 Sustainable Manufacturing Practices

Sustainability is becoming increasingly important in manufacturing. Advanced fluid chemical equipment parts contribute to sustainability efforts by reducing waste, minimizing resource consumption, and enabling closed-loop processes that recycle materials.

6. Application Areas of Advanced Fluid Chemical Equipment Parts

Advanced fluid chemical equipment parts find applications across various industries, each benefitting from their unique capabilities.

6.1 Chemical Manufacturing

In chemical manufacturing, these parts are essential for ensuring that processes run smoothly, chemicals are handled safely, and environmental regulations are adhered to.

6.2 Pharmaceutical Industry

The pharmaceutical industry relies heavily on precise fluid handling. Advanced equipment ensures that active ingredients are mixed accurately, and that products are manufactured under stringent quality control measures.

6.3 Food and Beverage Sector

In food and beverage manufacturing, maintaining hygiene and safety is crucial. Advanced fluid chemical equipment helps achieve these objectives while optimizing production efficiency.

7. Best Practices for Implementing Advanced Equipment

To maximize the benefits of advanced fluid chemical equipment parts, manufacturers should consider the following best practices:

- **Conduct Thorough Research**: Understanding the specific needs of the manufacturing process will guide the selection of the right equipment.

- **Invest in Training**: Ensuring that staff are trained to operate and maintain advanced equipment is essential for maximizing efficiency and safety.

- **Regular Maintenance**: Implementing a routine maintenance schedule helps prevent breakdowns and ensures optimal performance of equipment.

Advanced fluid chemical equipment parts are essential to unlocking efficiency in modern manufacturing. By enhancing productivity, quality control, and safety, these components play a crucial role in the overall success of manufacturing processes. As industries continue to evolve, embracing innovations and best practices related to fluid handling will be vital for maintaining competitiveness and meeting the demands of a rapidly changing market. Investing in these advanced technologies is no longer optional but a necessity for manufacturers aiming to thrive in today's landscape.

Dalian Sakabe was invited to participate in the Dalian investment promotion project ceremony

On March 27, 2025, Dalian Sakabe, as an advanced foreign-funded enterprise in Dalian, was invited to participate in the investment promotion project ceremony of Dalian China.

2025/04/01

It is pleased that partner NME come to visit us Sakabe foundry

It is pleased that partner NME come to visit us Sakabe foundry. We share the same philosophy about quality standards, product positioning, environmental protection, and sustainable development. It's lucky to meet like-minded partners!

2025/02/19

Great meeting with partner in Shanghai

Dalian Sakabe paying visit to our partner TST in Shanghai. Had discussions and plans for long term co-operation. Great thanks for your support!

2025/01/02