Flowmeters are essential instruments used to measure the flow rate of liquids or gases in various industrial applications. The durability of flowmeter components is crucial, as they often operate in challenging environments subject to high pressure, temperature fluctuations, and corrosive substances. Therefore, the casting of flowmeter parts must prioritize strength and resilience to maintain optimal performance over time.

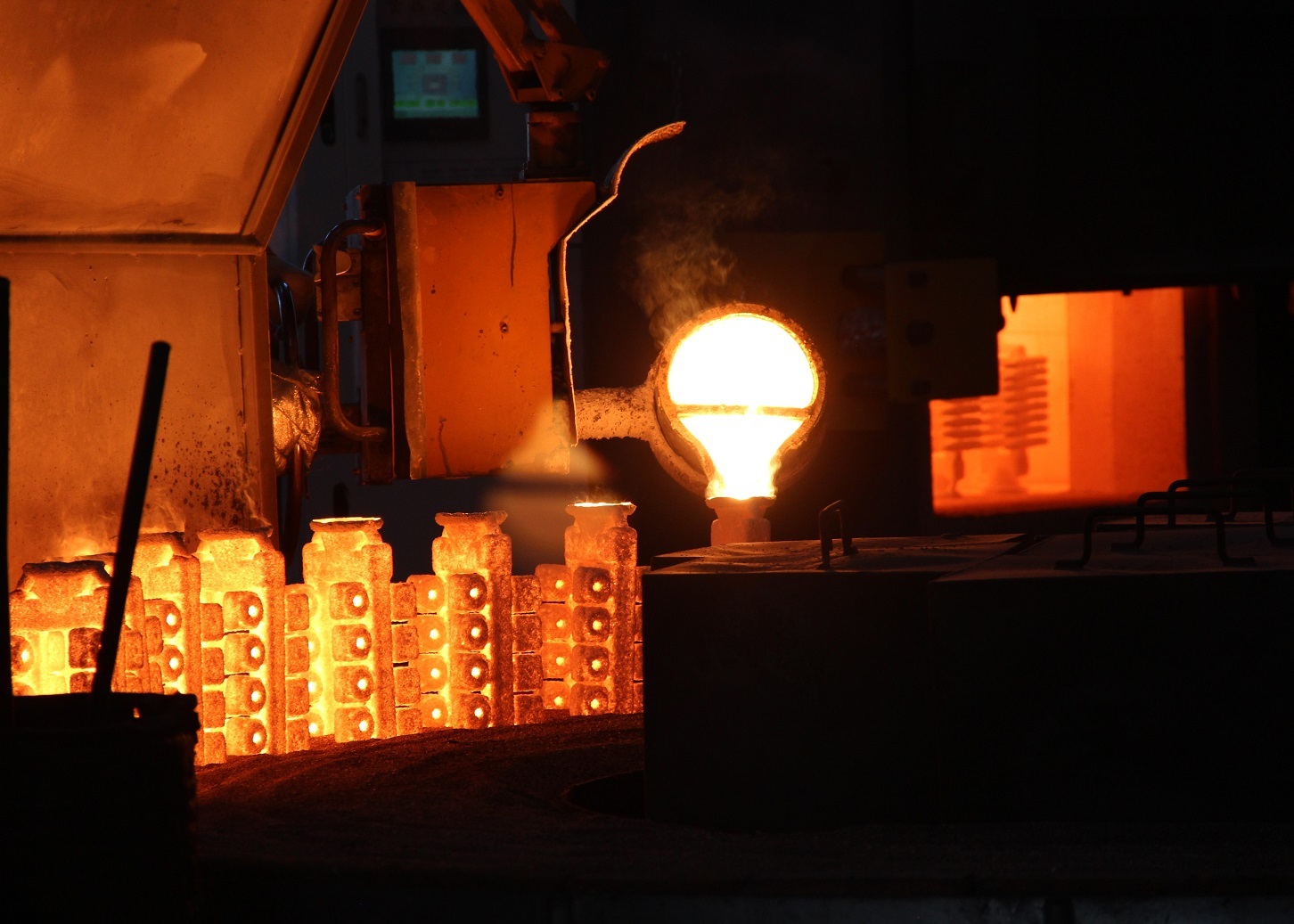

The casting process involves pouring molten material into a mold, where it solidifies into the desired shape. For flowmeter parts, common materials include metals like stainless steel and aluminum, as well as specialized alloys designed for specific applications. These materials are chosen for their strength, corrosion resistance, and ability to withstand thermal stress. The selection of the right material is paramount in ensuring that the flowmeter parts can endure the rigors of their operating conditions.

Several casting techniques are utilized in the manufacturing of durable flowmeter parts. Sand casting, investment casting, and die casting are some of the most widely used methods. Each technique has its unique advantages. For instance, sand casting is cost-effective and versatile, making it suitable for producing large or complex parts. Investment casting, on the other hand, allows for high precision and excellent surface finish, which is critical for components that require accurate flow measurement. Die casting can produce parts with thin walls and intricate details, making it ideal for mass production of flowmeter components.

In addition to the casting process, post-casting treatments such as heat treatment and surface finishing can significantly enhance the durability of flowmeter parts. Heat treatment can improve the material properties, such as hardness and toughness, while surface finishing techniques, like coating or polishing, can provide additional protection against wear and corrosion.

Investing in quality durable flowmeter parts is essential for manufacturers looking to optimize their operations. By ensuring that these components are crafted through reliable casting processes, businesses can minimize downtime, reduce maintenance costs, and enhance overall productivity. Moreover, the longevity of flowmeter parts directly impacts the accuracy of measurements, thus contributing to better resource management and operational efficiency.

In conclusion, the casting of durable flowmeter parts is a critical aspect of mechanical hardware manufacturing. Understanding the materials, methods, and treatments involved in this process can help manufacturers select the right components that ensure reliability and longevity in their operations. By focusing on quality and durability, businesses can achieve significant improvements in performance and efficiency.

The casting process involves pouring molten material into a mold, where it solidifies into the desired shape. For flowmeter parts, common materials include metals like stainless steel and aluminum, as well as specialized alloys designed for specific applications. These materials are chosen for their strength, corrosion resistance, and ability to withstand thermal stress. The selection of the right material is paramount in ensuring that the flowmeter parts can endure the rigors of their operating conditions.

Several casting techniques are utilized in the manufacturing of durable flowmeter parts. Sand casting, investment casting, and die casting are some of the most widely used methods. Each technique has its unique advantages. For instance, sand casting is cost-effective and versatile, making it suitable for producing large or complex parts. Investment casting, on the other hand, allows for high precision and excellent surface finish, which is critical for components that require accurate flow measurement. Die casting can produce parts with thin walls and intricate details, making it ideal for mass production of flowmeter components.

In addition to the casting process, post-casting treatments such as heat treatment and surface finishing can significantly enhance the durability of flowmeter parts. Heat treatment can improve the material properties, such as hardness and toughness, while surface finishing techniques, like coating or polishing, can provide additional protection against wear and corrosion.

Investing in quality durable flowmeter parts is essential for manufacturers looking to optimize their operations. By ensuring that these components are crafted through reliable casting processes, businesses can minimize downtime, reduce maintenance costs, and enhance overall productivity. Moreover, the longevity of flowmeter parts directly impacts the accuracy of measurements, thus contributing to better resource management and operational efficiency.

In conclusion, the casting of durable flowmeter parts is a critical aspect of mechanical hardware manufacturing. Understanding the materials, methods, and treatments involved in this process can help manufacturers select the right components that ensure reliability and longevity in their operations. By focusing on quality and durability, businesses can achieve significant improvements in performance and efficiency.

Development prospects of investment casting

The products obtained by investment casting are precise and complex, close to the final shape of the parts, and can be directly used without or with little machining. It is an advanced technology for near net formation and an excellent process technology in the casting industry, with a wide range of applications. It is suitable for casting various types of alloys, and the produced castings have higher dimensional accuracy and surface quality than other casting methods. Even complex, high-temperature resistant, and difficult to process castings can be cast using investment casting precision casting.

2024/10/08