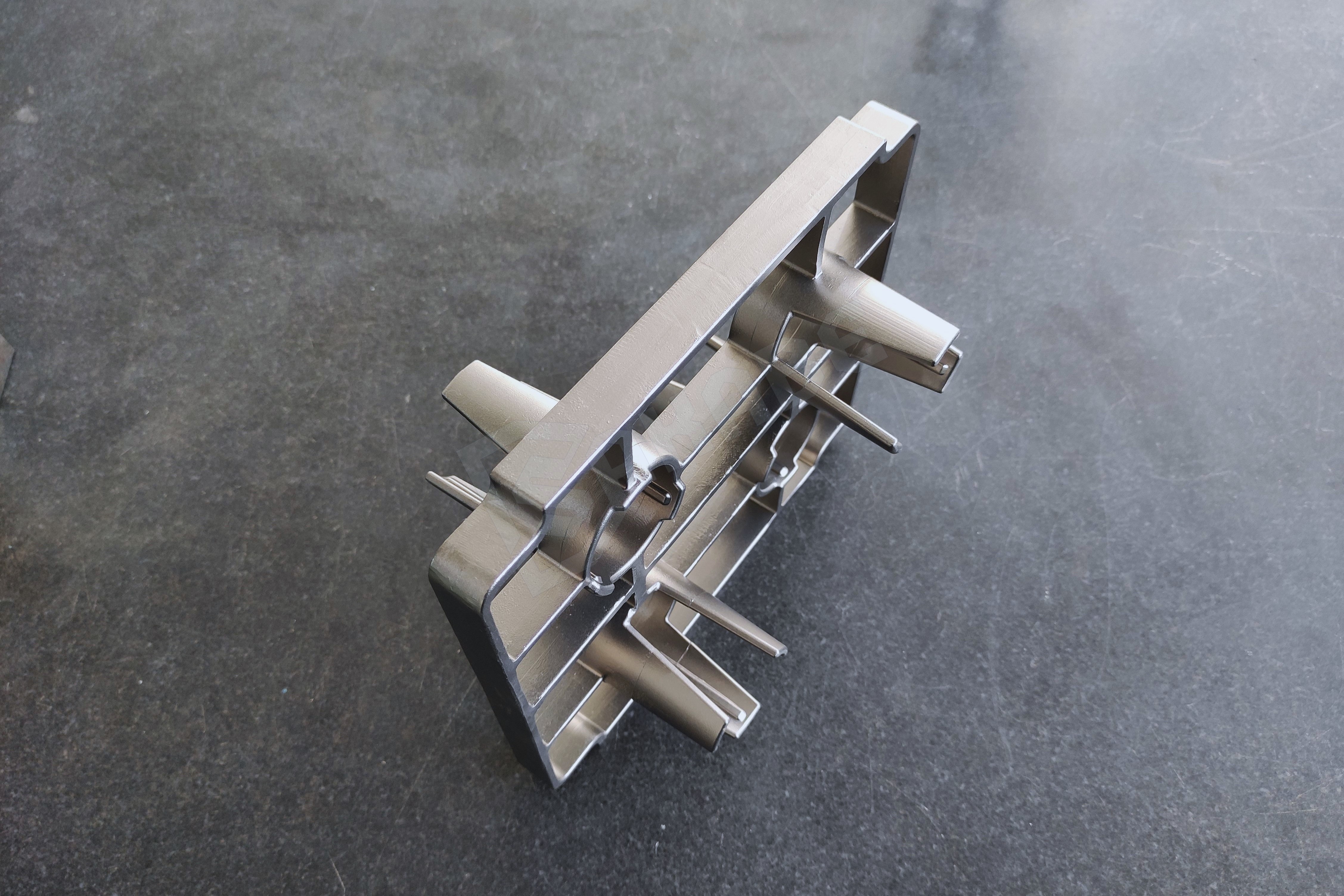

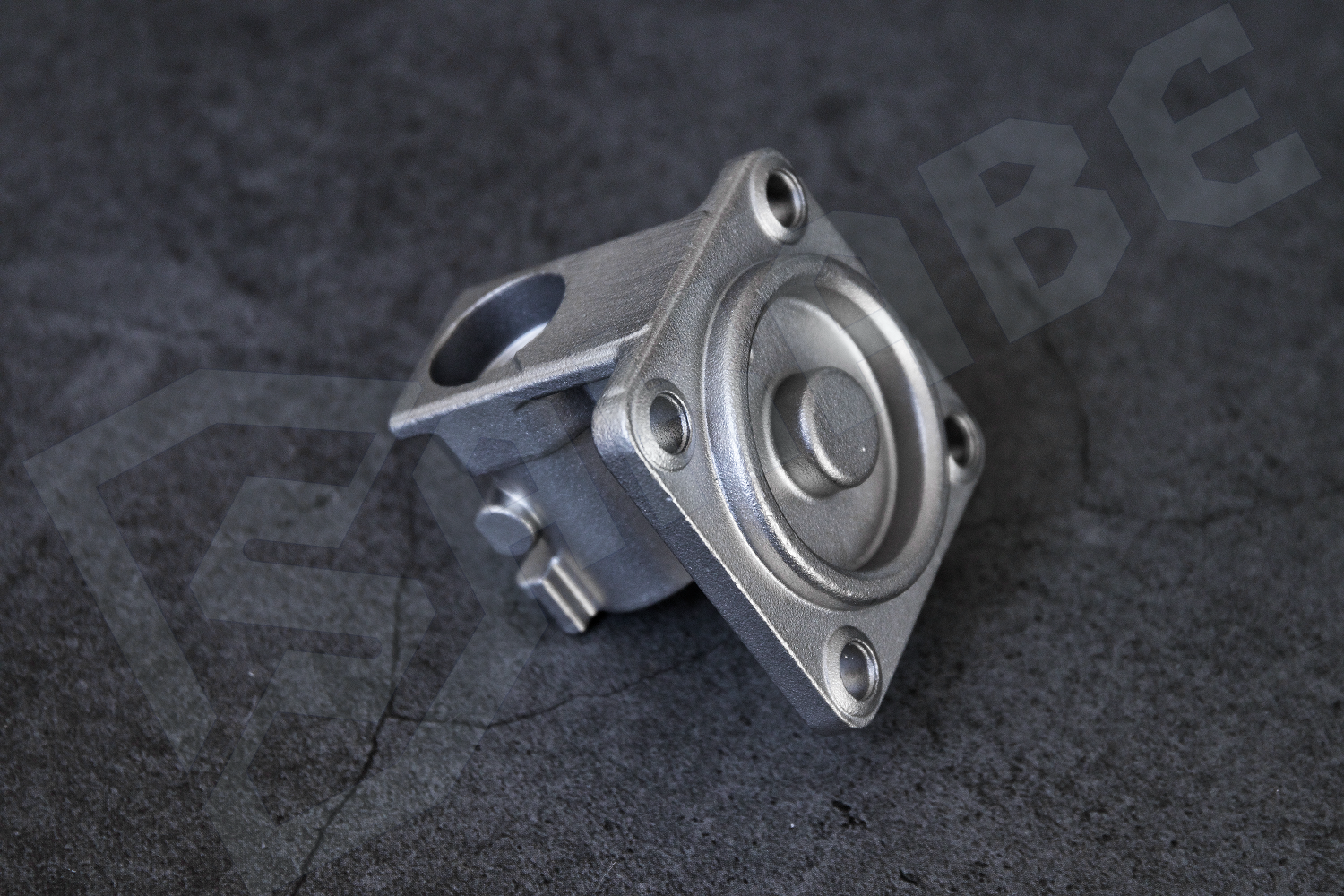

Fluid chemical equipment casting parts are integral components in the manufacturing and processing of various fluids, particularly in industries that require efficient handling of chemical substances. These parts are typically crafted from materials such as metal alloys, which are then molded into specific shapes to meet the operational requirements of different applications. The casting process involves pouring molten metal into a mold, allowing it to cool and solidify, thus creating a precise part that can withstand the rigors of chemical environments.

The importance of fluid chemical equipment casting parts cannot be overstated. They are designed to operate under high pressure and temperature conditions, making them essential for maintaining the integrity of systems used in chemical processing, pharmaceuticals, and even food and beverage industries. Their durability ensures that they can effectively manage the movement of fluids without the risk of leaks or failures, which could lead to costly Downtime and safety hazards.

In the casting process, several factors come into play that influence the quality and performance of the final product. These include the selection of the right materials, the design of the mold, and the precision involved in the casting technique. Advanced technologies such as computer-aided design (CAD) are often employed to create intricate molds that can accommodate complex shapes and specifications. This level of precision is critical in ensuring that the casting parts fit perfectly into their designated applications.

Moreover, the manufacturing of fluid chemical equipment casting parts is subject to stringent quality control measures. This ensures that each component meets the required industry standards and regulatory compliance, guaranteeing safety and reliability. Techniques such as non-destructive testing (NDT) are frequently used to examine the integrity of the cast parts, detecting any potential flaws that could compromise their functionality.

Another key aspect to consider is the role of surface treatment in enhancing the performance of casting parts. Surface treatments, such as coatings and finishes, can significantly improve corrosion resistance and reduce wear and tear, extending the lifespan of these components in harsh chemical environments.

In summary, fluid chemical equipment casting parts play a crucial role in various industries, providing essential support for the safe and efficient movement of fluids. Their production involves a meticulous process that prioritizes quality, precision, and compliance with industry standards. Understanding the significance of these components can help professionals make informed decisions regarding their applications, leading to improved operational efficiency and safety in their respective fields.

The importance of fluid chemical equipment casting parts cannot be overstated. They are designed to operate under high pressure and temperature conditions, making them essential for maintaining the integrity of systems used in chemical processing, pharmaceuticals, and even food and beverage industries. Their durability ensures that they can effectively manage the movement of fluids without the risk of leaks or failures, which could lead to costly Downtime and safety hazards.

In the casting process, several factors come into play that influence the quality and performance of the final product. These include the selection of the right materials, the design of the mold, and the precision involved in the casting technique. Advanced technologies such as computer-aided design (CAD) are often employed to create intricate molds that can accommodate complex shapes and specifications. This level of precision is critical in ensuring that the casting parts fit perfectly into their designated applications.

Moreover, the manufacturing of fluid chemical equipment casting parts is subject to stringent quality control measures. This ensures that each component meets the required industry standards and regulatory compliance, guaranteeing safety and reliability. Techniques such as non-destructive testing (NDT) are frequently used to examine the integrity of the cast parts, detecting any potential flaws that could compromise their functionality.

Another key aspect to consider is the role of surface treatment in enhancing the performance of casting parts. Surface treatments, such as coatings and finishes, can significantly improve corrosion resistance and reduce wear and tear, extending the lifespan of these components in harsh chemical environments.

In summary, fluid chemical equipment casting parts play a crucial role in various industries, providing essential support for the safe and efficient movement of fluids. Their production involves a meticulous process that prioritizes quality, precision, and compliance with industry standards. Understanding the significance of these components can help professionals make informed decisions regarding their applications, leading to improved operational efficiency and safety in their respective fields.