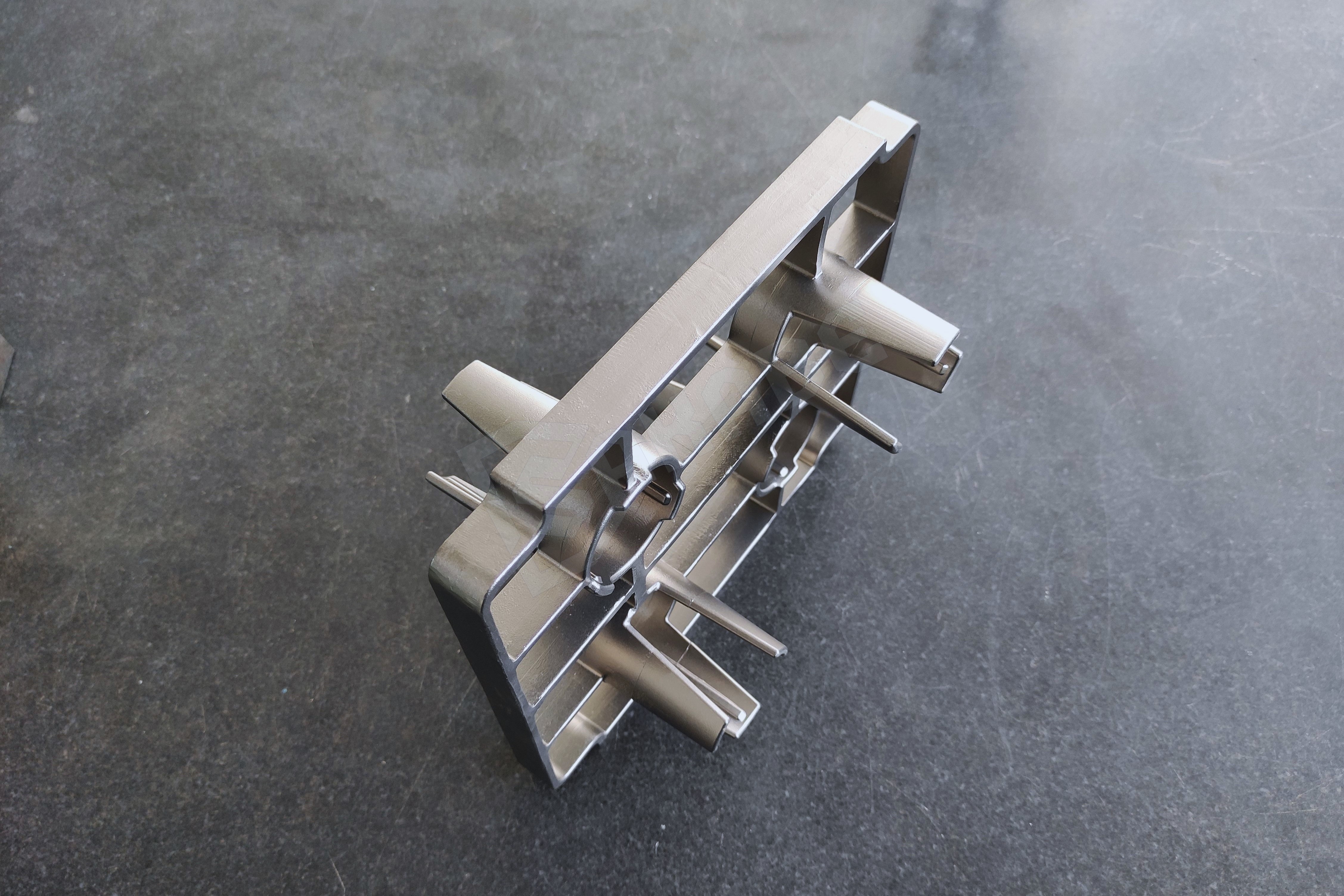

Investment casting, often referred to as lost-wax casting, is a manufacturing process used to create complex and precise metal components. This technique is particularly advantageous in producing flowmeter housings, as it allows for intricate designs and high dimensional accuracy. The process begins with the creation of a wax pattern that represents the final product. This pattern is then coated with a ceramic shell, which hardens and forms a mold. Once the shell is complete, the wax is melted away, leaving behind a hollow ceramic mold ready for metal casting.

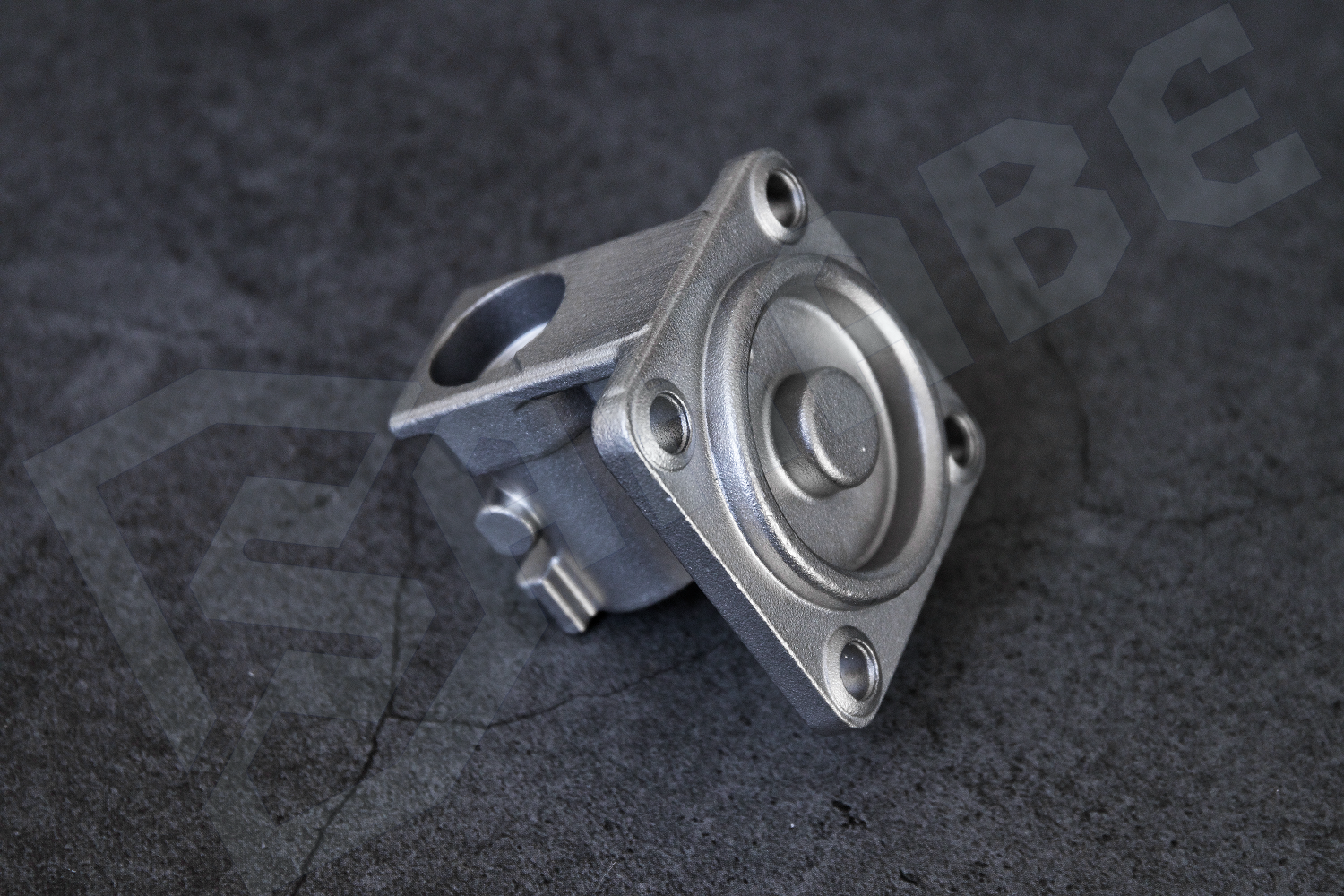

One of the key benefits of using investment casting for flowmeter housing is its ability to produce components with exceptional surface finishes. The precision of the mold allows manufacturers to minimize machining requirements, reducing production time and costs. This is especially important in the flowmeter industry, where accuracy and reliability are crucial for measuring fluid dynamics.

Another advantage of investment casting lies in its versatility. Various metals and alloys can be utilized in this process, including stainless steel, aluminum, and bronze, allowing manufacturers to choose materials that best suit their specific applications. This flexibility is essential in flowmeter production, where different environments may require different materials to withstand pressure, temperature, or corrosive substances.

Moreover, investment casting is capable of producing large quantities of parts with uniform quality. Once the initial mold is created, multiple components can be cast simultaneously, leading to higher productivity. This mass production capability is crucial for industries that demand a consistent supply of flowmeter housings without compromising on quality.

In addition to its practical benefits, investment casting also supports sustainable practices in manufacturing. The process generates minimal waste since the wax can be recycled and reused for future patterns. This not only conserves resources but also aligns with the growing emphasis on environmentally friendly manufacturing methods.

Overall, investment casting for flowmeter housing is a sophisticated and efficient method that delivers high-quality results. By combining precision, versatility, and sustainability, this casting technique meets the complex demands of modern manufacturing. Understanding the intricacies of investment casting can help professionals make informed decisions and optimize their production processes, ensuring that they produce reliable and accurate flowmeter housings tailored to their customers' needs.

One of the key benefits of using investment casting for flowmeter housing is its ability to produce components with exceptional surface finishes. The precision of the mold allows manufacturers to minimize machining requirements, reducing production time and costs. This is especially important in the flowmeter industry, where accuracy and reliability are crucial for measuring fluid dynamics.

Another advantage of investment casting lies in its versatility. Various metals and alloys can be utilized in this process, including stainless steel, aluminum, and bronze, allowing manufacturers to choose materials that best suit their specific applications. This flexibility is essential in flowmeter production, where different environments may require different materials to withstand pressure, temperature, or corrosive substances.

Moreover, investment casting is capable of producing large quantities of parts with uniform quality. Once the initial mold is created, multiple components can be cast simultaneously, leading to higher productivity. This mass production capability is crucial for industries that demand a consistent supply of flowmeter housings without compromising on quality.

In addition to its practical benefits, investment casting also supports sustainable practices in manufacturing. The process generates minimal waste since the wax can be recycled and reused for future patterns. This not only conserves resources but also aligns with the growing emphasis on environmentally friendly manufacturing methods.

Overall, investment casting for flowmeter housing is a sophisticated and efficient method that delivers high-quality results. By combining precision, versatility, and sustainability, this casting technique meets the complex demands of modern manufacturing. Understanding the intricacies of investment casting can help professionals make informed decisions and optimize their production processes, ensuring that they produce reliable and accurate flowmeter housings tailored to their customers' needs.