How Die-Casting Parts Enhance the Durability of Sewing Machines

Table of Contents

- Introduction to Die-Casting in Sewing Machines

- Understanding Die-Casting: An Overview

- Advantages of Die-Casting for Sewing Machine Parts

- Durability Features of Die-Cast Parts

- Applications of Die-Casting in Sewing Machines

- Die-Casting vs. Other Manufacturing Methods

- The Future of Die-Casting in Sewing Machine Technology

- Conclusion: The Lasting Impact of Die-Casting on Sewing Machines

- Frequently Asked Questions

Introduction to Die-Casting in Sewing Machines

The sewing machine industry has continually evolved to meet growing demands for efficiency and durability. One of the critical advancements lies in the use of **die-casting parts**. These components not only enhance the performance of sewing machines but also significantly improve their longevity. In this article, we delve into the intricacies of how die-casting contributes to the overall durability of sewing machines, exploring the processes involved, advantages, and future prospects.

Understanding Die-Casting: An Overview

Die-casting is a manufacturing process used to produce parts by forcing molten metal into a mold cavity. This method is characterized by high efficiency and precision, allowing for the production of complex shapes with high dimensional accuracy. **Aluminum**, **zinc**, and **magnesium** alloys are commonly used materials in die-casting, each offering unique strengths and properties.

The die-casting process can be broken down into several key stages:

1. **Mold Preparation:** The mold is crafted from durable materials, typically steel, to withstand high pressure and temperature.

2. **Metal Injection:** Molten metal is injected into the mold at high speed, ensuring that the cavity fills completely.

3. **Cooling and Solidification:** The metal cools and solidifies within the mold, taking on its final shape.

4. **Ejection:** Once cooled, the finished part is ejected from the mold and undergoes any necessary finishing processes.

This method results in parts that have a smooth surface finish and require little to no machining, making die-casting an ideal choice for sewing machine components.

Advantages of Die-Casting for Sewing Machine Parts

The die-casting method presents a myriad of advantages that make it a preferred choice for manufacturing sewing machine parts. Some of the most notable benefits include:

1. Enhanced Strength and Durability

Die-casting produces parts that are significantly stronger than those made from other processes. The high pressure at which molten metal is injected contributes to a denser, more robust final product. This strength translates into improved durability for sewing machines, allowing them to withstand the rigors of continuous use.

2. Precision Engineering

With die-casting, manufacturers can achieve a high level of precision in the dimensions of sewing machine parts. This ensures that components fit together seamlessly, reducing the likelihood of mechanical failures that stem from imprecise fitting.

3. Cost-Effectiveness in Mass Production

Die-casting is highly efficient for mass production. Because the process allows for rapid production cycles and a reduction in waste material, it can lead to lower costs per unit when producing large quantities of parts. This is particularly advantageous for sewing machine manufacturers, who often require numerous identical components.

4. Versatility in Design

Die-casting accommodates a wide range of designs and configurations. Manufacturers can produce intricate shapes and hollow designs that would be challenging or impossible to achieve with traditional machining. This flexibility allows for continuous innovation in sewing machine design.

5. Smooth Surface Finish

The die-casting process results in parts with a smooth surface finish, reducing the need for additional surface treatments. A smooth finish enhances the aesthetic appeal of sewing machines while also contributing to their functional performance.

Durability Features of Die-Cast Parts

Die-cast parts exhibit several durability features that significantly benefit sewing machines:

1. Wear Resistance

Sewing machines are subject to frequent motion and friction. Components made from die-cast metals, particularly aluminum and zinc alloys, showcase excellent wear resistance, ensuring that parts remain effective over prolonged periods.

2. Corrosion Resistance

Many die-cast alloys possess inherent corrosion resistance, making them suitable for environments where exposure to moisture or chemicals is a concern. This quality extends the lifespan of sewing machines, reducing maintenance needs.

3. Thermal Stability

Die-cast parts can endure high temperatures without warping or degrading in performance. This thermal stability is crucial in sewing machines, where motors and other components generate considerable heat during operation.

4. Dimensional Stability

Die-casting offers superior dimensional stability compared to other manufacturing methods. This means that parts will maintain their shape and fit even under stress, contributing to the overall functionality of the sewing machine.

Applications of Die-Casting in Sewing Machines

Die-casting plays a vital role in the production of numerous sewing machine components. Some common applications include:

1. Body Components

The main body of sewing machines often utilizes die-cast aluminum or zinc parts, providing a lightweight yet strong structure that enhances portability without sacrificing durability.

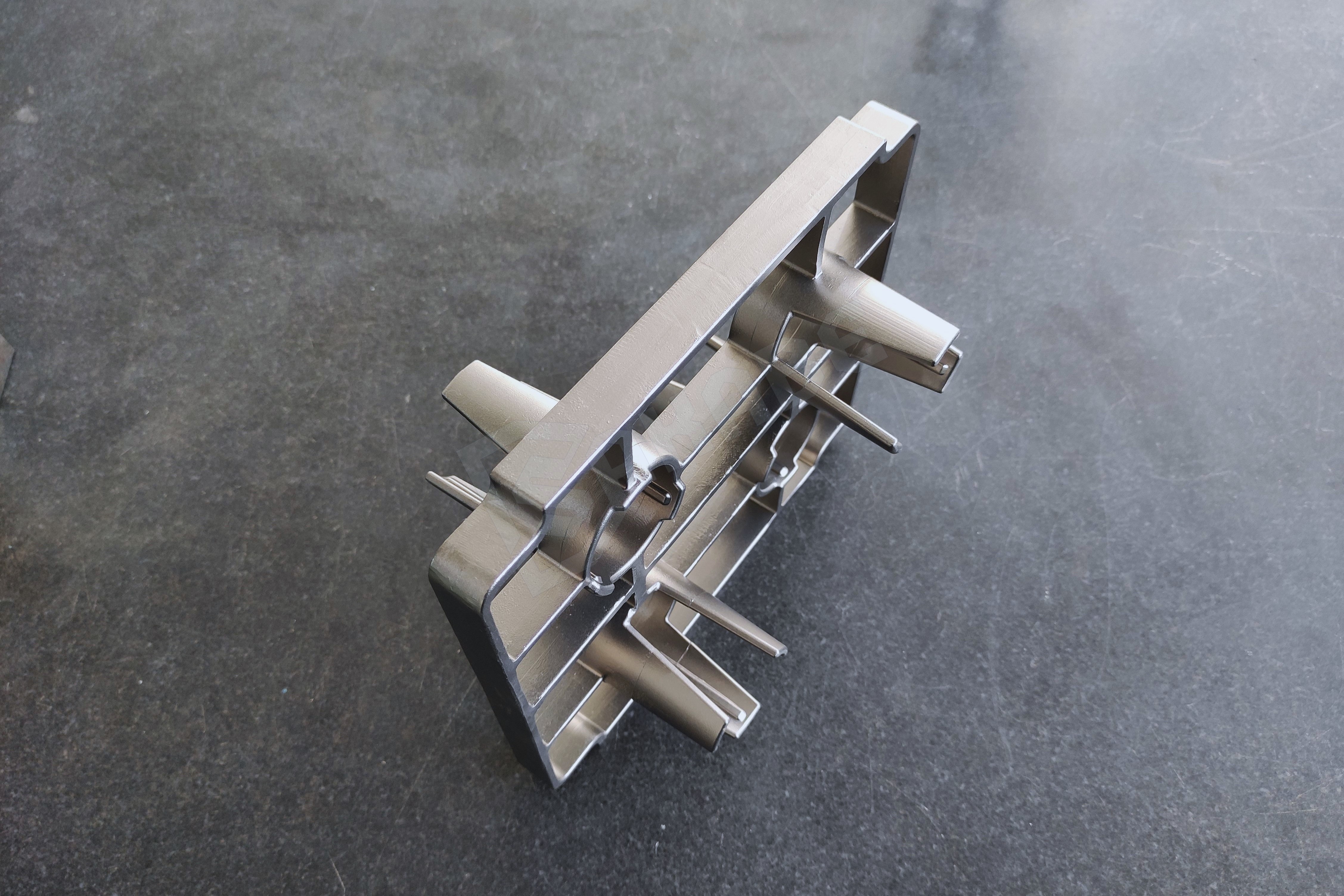

2. Gear and Drive Assemblies

Die-cast gears and drive components ensure smooth operation and longevity. The precision achieved in die-casting minimizes the risk of mechanical failures that can disrupt sewing tasks.

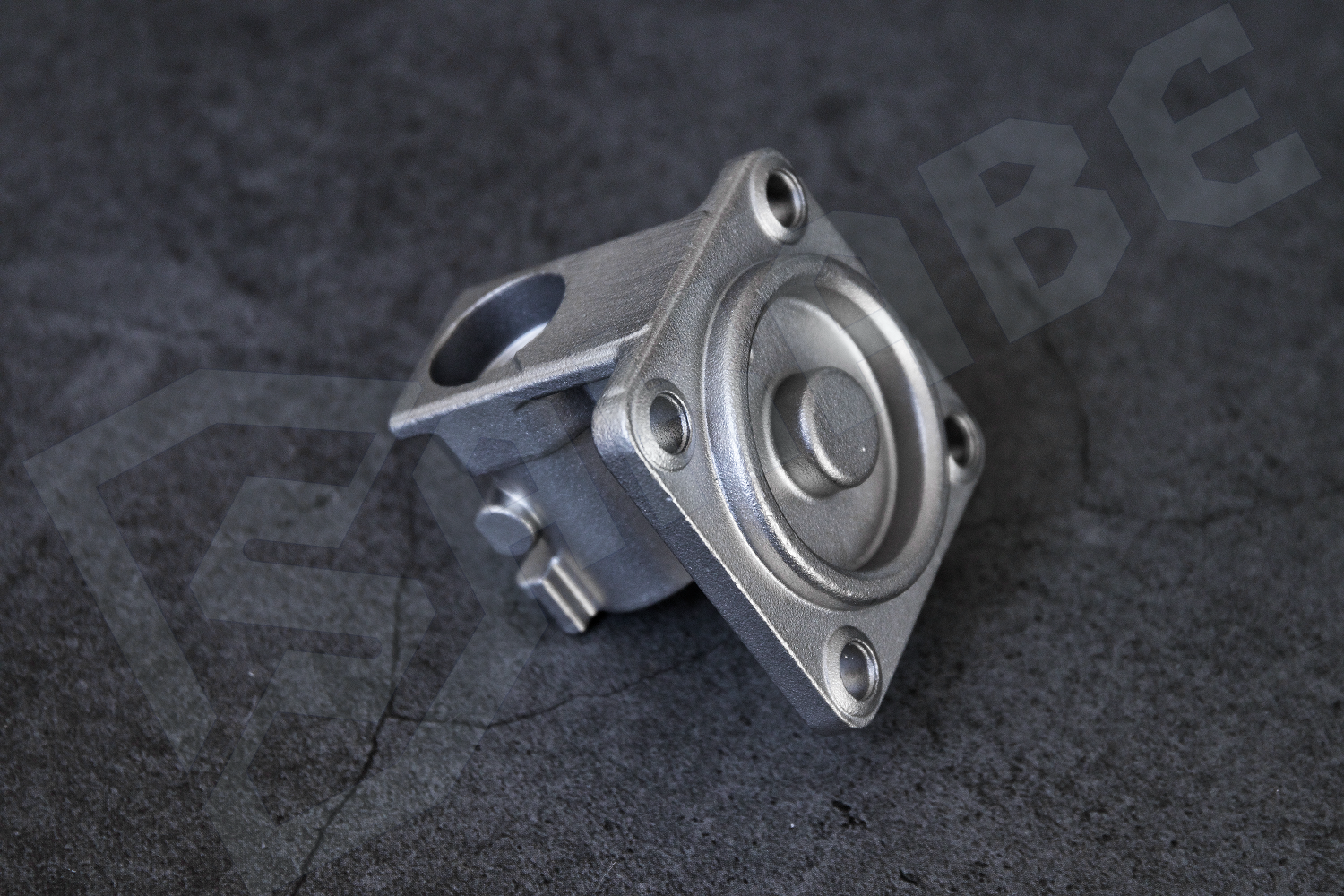

3. Motor Housings

The durability and thermal resistance of die-cast parts make them ideal for motor housings, which require protection from heat and wear while maintaining a snug fit for efficient operation.

4. Decorative Elements

In addition to functional components, die-casting allows manufacturers to produce decorative elements that enhance the visual appeal of sewing machines, appealing to a broader market.

Die-Casting vs. Other Manufacturing Methods

When examining the manufacturing of sewing machine parts, die-casting stands out compared to other methods, such as machining, forging, or injection molding.

1. Machining

While machining offers precision, it often results in higher material waste and longer production times. Die-casting, on the other hand, combines accuracy with efficiency, making it more suitable for high-volume production.

2. Forging

Forging produces strong components but is generally limited to simpler shapes. Die-casting allows for more complex designs without compromising strength, making it more versatile.

3. Injection Molding

Injection molding is primarily used for plastics. While it offers excellent detail and surface finish, die-casting provides superior metal properties, including strength and thermal resistance, crucial for sewing machine durability.

The Future of Die-Casting in Sewing Machine Technology

As technology advances, the die-casting industry continues to evolve. Innovations in materials, processes, and design techniques are likely to enhance the quality and performance of die-cast parts further. With the rise of smart sewing machines and automation, die-casting will play an essential role in meeting the needs of tomorrow's sewing technology.

Conclusion: The Lasting Impact of Die-Casting on Sewing Machines

Die-casting significantly contributes to the durability and efficiency of sewing machines, offering advantages that are difficult to replicate through other manufacturing methods. From enhanced strength and precision to versatile applications and cost-effectiveness, the benefits of die-casting are clear. As the industry advances and new technologies emerge, the role of die-casting in sewing machine production will only become more critical, ensuring that these essential tools remain reliable and efficient for users around the world.

Frequently Asked Questions

1. What is die-casting?

Die-casting is a manufacturing process where molten metal is injected under high pressure into a mold to create parts with high dimensional accuracy.

2. What materials are commonly used in die-casting?

The most common materials used in die-casting include aluminum, zinc, and magnesium alloys.

3. How does die-casting improve sewing machine durability?

Die-casting produces strong, wear-resistant parts that can withstand the demands of continuous use, thereby enhancing the overall durability of sewing machines.

4. What are the advantages of die-casting over machining?

Die-casting is generally faster, produces less waste, and allows for more complex shapes compared to traditional machining methods.

5. Are die-cast parts suitable for high-temperature applications?

Yes, many die-cast alloys have excellent thermal stability, making them suitable for applications where heat resistance is important, such as motor housings in sewing machines.