The Comprehensive Guide to Dewax Casting in Equipment Manufacturing

Table of Contents

1. Introduction to Dewax Casting in Equipment Manufacturing

2. Understanding the Dewax Casting Process

3. Advantages of Dewax Casting in Manufacturing

3.1 Enhanced Precision and Detail

3.2 Cost-Effectiveness and Efficiency

4. Applications of Dewax Casting in Mechanical Manufacturing

4.1 Aerospace Components

4.2 Automotive Parts

4.3 Industrial Machinery

5. Common Materials Used in Dewax Casting

6. Challenges in the Dewax Casting Process

6.1 Wax Residue Issues

6.2 Shrinkage and Distortion

7. Best Practices for Successful Dewax Casting

8. Future Trends in Dewax Casting Technology

9. Frequently Asked Questions (FAQs)

10. Conclusion

1. Introduction to Dewax Casting in Equipment Manufacturing

Dewax casting, also known as investment casting or lost wax casting, is a highly sophisticated method used in the manufacturing of mechanical components and machinery. This process leverages wax patterns to create intricate molds, allowing for precise and intricate designs that are essential in modern equipment manufacturing. The dewax casting technique is particularly valued for its ability to produce high-quality parts with excellent surface finishes and dimensional accuracy.

2. Understanding the Dewax Casting Process

The dewax casting process involves several critical stages. Initially, a wax pattern is produced, which is a precise replica of the final component. This wax pattern is then coated with a ceramic shell, and the assembly is heated to eliminate the wax, leaving behind a mold cavity. Liquid metal is subsequently poured into this mold to create the desired part.

The entire process can be broken down into the following steps:

1. **Wax Pattern Creation**: High-quality wax is molded to form the patterns of the components to be produced.

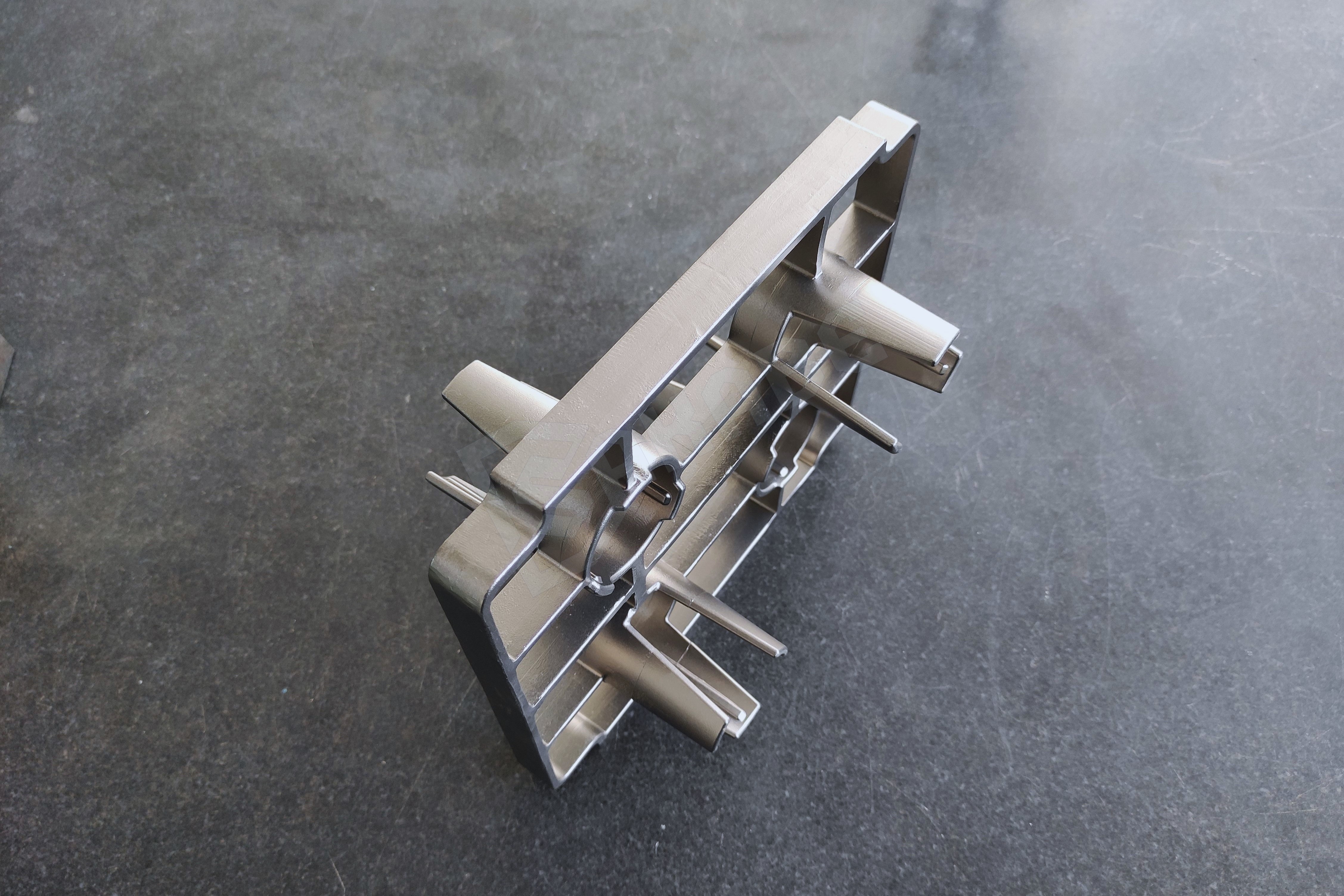

2. **Assembly**: Multiple wax patterns can be attached to form a "tree," allowing for the simultaneous creation of several parts.

3. **Shell Building**: The assembled wax patterns are coated with a ceramic material, typically through a dipping and sand application process.

4. **Dewaxing**: The assembly is heated, usually in an autoclave, to melt and drain the wax, leaving a hollow ceramic shell.

5. **Metal Pouring**: Molten metal is poured into the ceramic mold to create the final part.

6. **Shell Removal**: Once the metal has cooled, the ceramic shell is broken away to reveal the casting.

7. **Finishing**: The final part undergoes finishing operations, including grinding, polishing, and any necessary machining.

3. Advantages of Dewax Casting in Manufacturing

Dewax casting offers numerous advantages that make it a preferred choice in equipment manufacturing.

3.1 Enhanced Precision and Detail

One of the most significant benefits of dewax casting is its ability to produce highly complex geometries with excellent surface finishes. The process allows for intricate designs that are often impossible to achieve with traditional machining methods. This precision is critical in industries such as aerospace and medicine, where component reliability is paramount.

3.2 Cost-Effectiveness and Efficiency

Dewax casting can be more cost-effective than other manufacturing methods, especially for small to medium production runs. The ability to cast multiple parts simultaneously reduces material waste and labor costs, thus optimizing overall production efficiency.

4. Applications of Dewax Casting in Mechanical Manufacturing

Dewax casting is utilized across a wide range of sectors within mechanical manufacturing. Here are some key applications:

4.1 Aerospace Components

In the aerospace industry, precision and reliability are non-negotiable. Dewax casting is often employed to create components such as turbine blades and housing casings, where even the slightest imperfection can lead to costly failures.

4.2 Automotive Parts

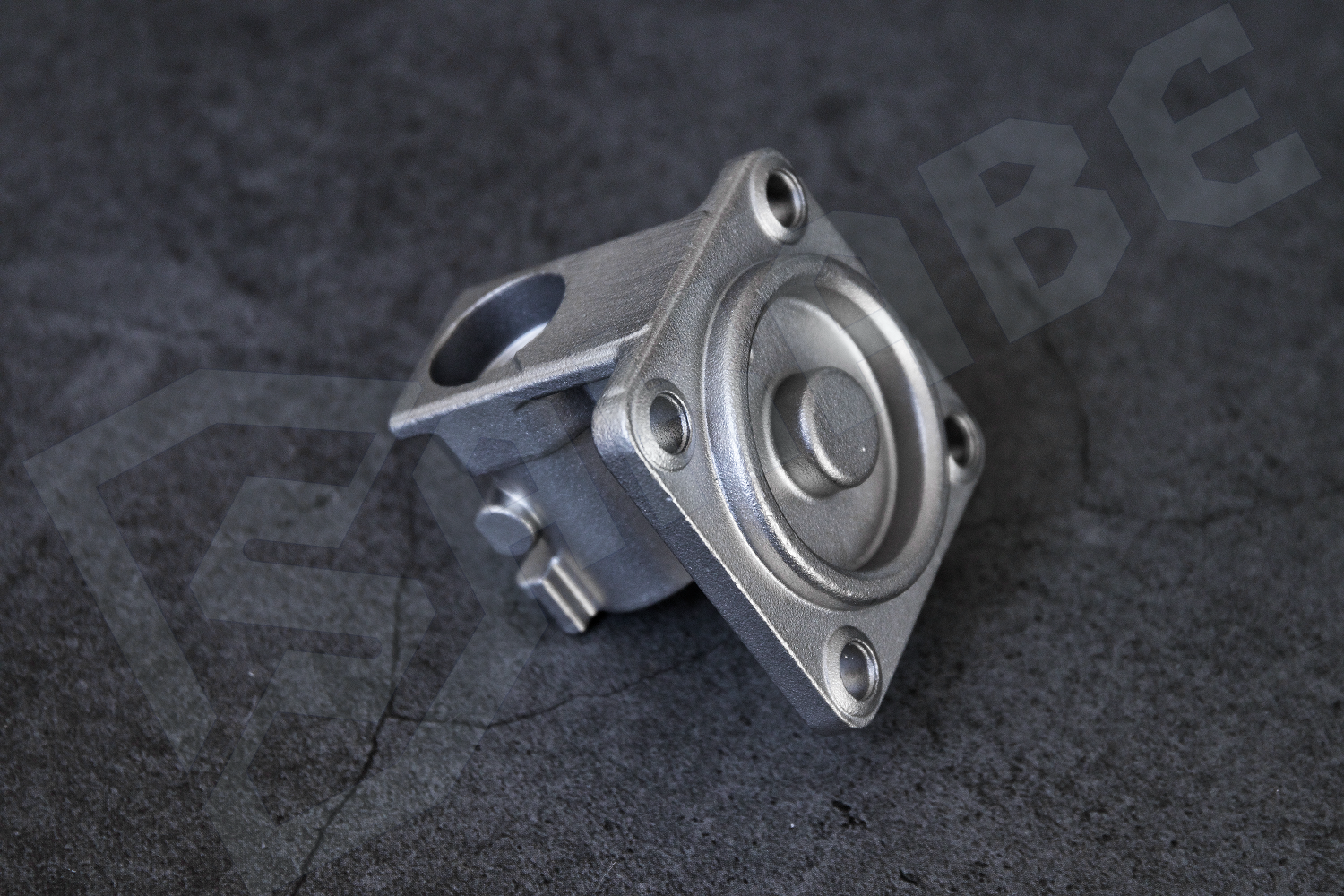

Automotive manufacturers leverage dewax casting for producing critical engine components like exhaust manifolds and valve bodies. The ability to produce lightweight yet strong parts significantly enhances vehicle performance.

4.3 Industrial Machinery

Dewax casting is also applied in the manufacturing of industrial machinery parts, including gears, brackets, and housing. The capability to produce intricate designs facilitates improved functionality and durability.

5. Common Materials Used in Dewax Casting

A variety of materials can be utilized in dewax casting, including:

- **Aluminum Alloys**: Lightweight with good thermal conductivity, making them ideal for automotive applications.

- **Steel Alloys**: Known for strength and durability, commonly used in machinery components.

- **Nickel Alloys**: Excellent for high-temperature and corrosive environments, often used in aerospace applications.

6. Challenges in the Dewax Casting Process

Despite its advantages, the dewax casting process is not without its challenges.

6.1 Wax Residue Issues

Incomplete removal of wax can lead to defects in the final product. It is crucial to ensure that all wax is eliminated during the dewaxing process to prevent weakness or failure in the cast component.

6.2 Shrinkage and Distortion

As metals cool, they can contract, which may result in dimensional changes. Proper design and mold preparation are essential to mitigate these issues and ensure the final product meets specifications.

7. Best Practices for Successful Dewax Casting

To achieve optimal results in dewax casting, consider the following best practices:

1. **Quality Wax Selection**: Utilize high-quality wax that can withstand the temperatures required for mold creation and dewaxing.

2. **Precision Mold Design**: Invest time in designing molds that account for shrinkage and allow for easy wax removal.

3. **Thorough Dewaxing Process**: Ensure that the dewaxing process is thoroughly executed to eliminate all wax residues.

4. **Quality Control**: Implement stringent quality control measures to monitor each stage of the casting process.

8. Future Trends in Dewax Casting Technology

As technology advances, the dewax casting process continues to evolve. Future trends may include:

- **Automation**: Increased automation in the dewax casting process to enhance efficiency and reduce human error.

- **3D Printing**: The integration of 3D printing technologies to create more complex molds and patterns.

- **Sustainable Practices**: Adoption of environmentally friendly materials and processes to minimize waste and energy consumption.

9. Frequently Asked Questions (FAQs)

What is dewax casting?

Dewax casting is a precision manufacturing process where a wax pattern is used to create a mold, which is then filled with molten metal to produce intricate components.

What are the main advantages of dewax casting?

The primary advantages include enhanced precision, complex geometries, cost-effectiveness for medium production runs, and excellent surface finishes.

In which industries is dewax casting commonly used?

Dewax casting is widely used in aerospace, automotive, and industrial machinery sectors.

What materials are commonly used in dewax casting?

Common materials include aluminum alloys, steel alloys, and nickel alloys.

What challenges can arise during the dewax casting process?

Challenges include wax residue issues and shrinkage or distortion of the cast components.

10. Conclusion

Dewax casting stands out as a highly effective method in the realm of equipment manufacturing, offering unparalleled precision and design flexibility. As industries evolve, embracing advancements in technology and sustainable practices will further enhance the capabilities of this casting method. By understanding the process, advantages, and applications of dewax casting, manufacturers can optimize their production lines, ensuring they remain competitive in a rapidly changing market.