Exploring the Advantages of Die-Casting Parts in Medical Equipment Manufacturing

Introduction to Die-Casting in Medical Equipment Manufacturing

In the rapidly evolving field of medical equipment manufacturing, precision and reliability are paramount. One of the most effective methods to achieve these standards is through **die-casting**. This manufacturing process involves forcing molten metal into a mold under high pressure, creating complex shapes with remarkable accuracy. The use of die-casting in medical equipment not only enhances the quality of the parts but also plays a crucial role in the overall **efficiency** and **cost-effectiveness** of production processes.

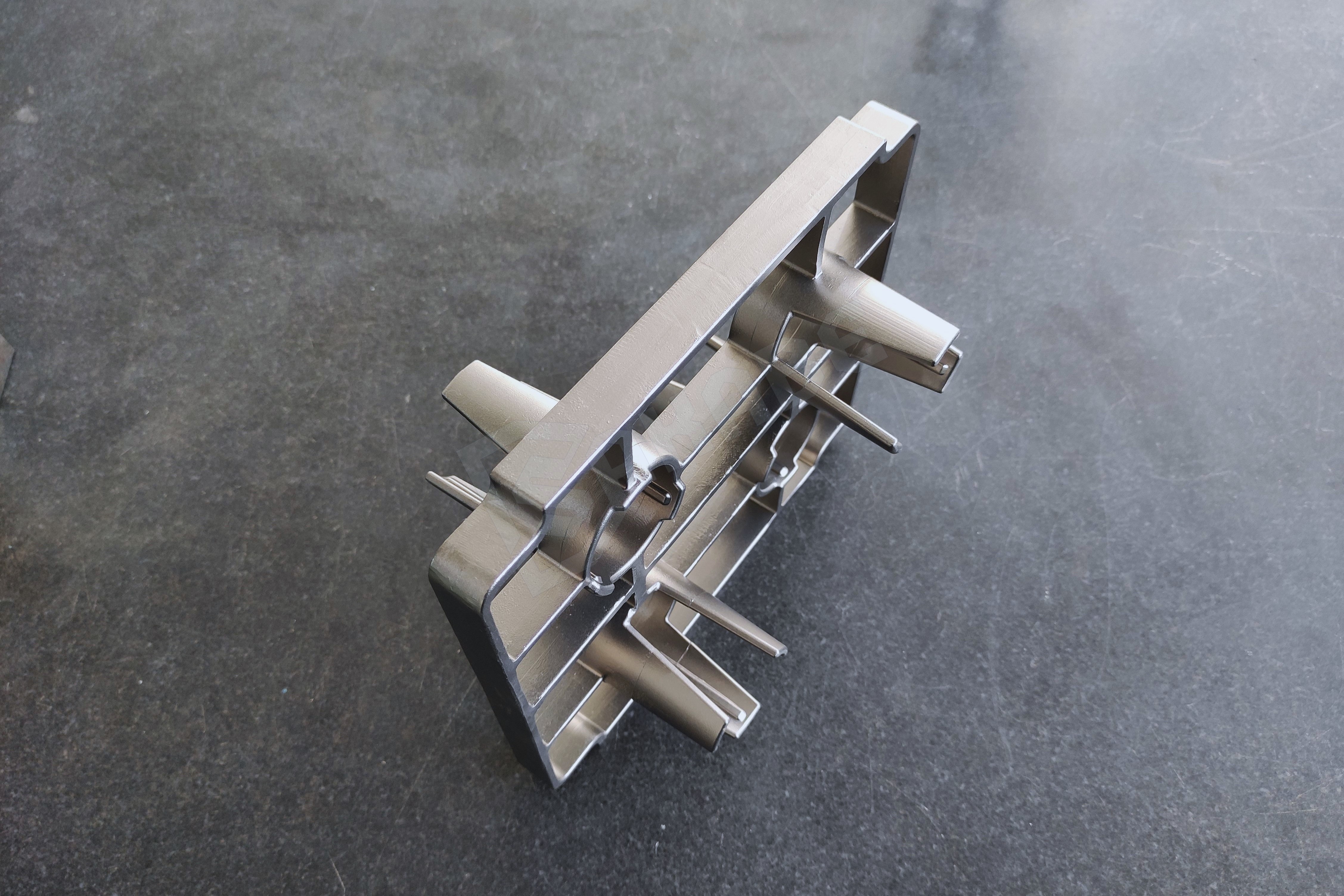

Understanding the Die-Casting Process

To fully appreciate the advantages of die-casting, it’s essential to understand the process itself. Die-casting involves several key stages:

The Initial Steps

1. **Mold Design**: Creating a mold that matches the desired specifications.

2. **Metal Preparation**: Melting the metal to the appropriate temperature.

3. **Injection**: Injecting the molten metal into the mold at high pressure.

Cooling and Ejection

After the metal is injected, it cools and solidifies within the mold. Once cooled, the mold opens, and the finished part is ejected.

Quality Control

Finally, rigorous testing and quality checks ensure that each part meets industry standards.

Key Advantages of Die-Casting in Medical Equipment Manufacturing

The adoption of die-casting in medical equipment manufacturing offers several critical benefits:

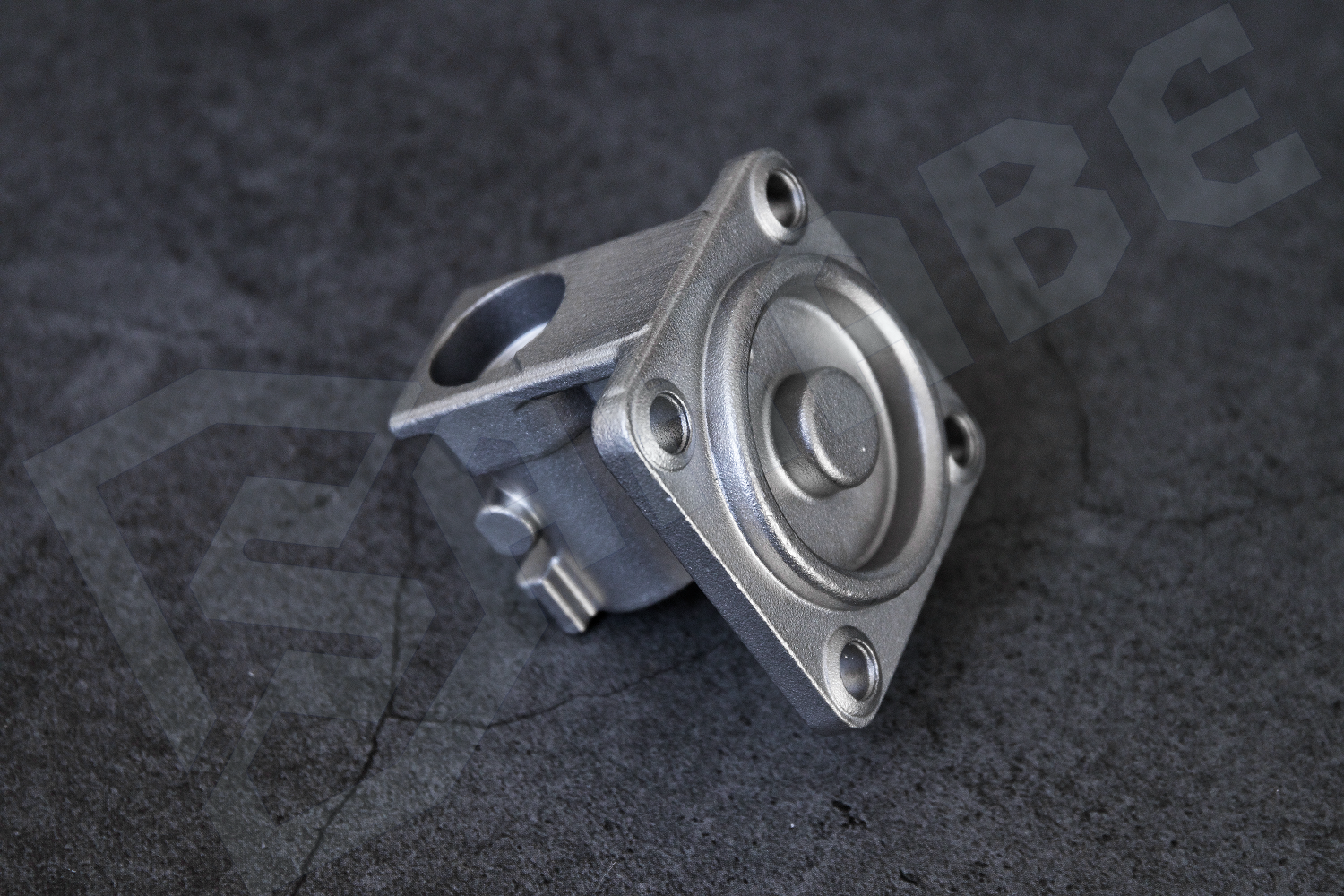

1. Precision and Accuracy

Die-casting provides exceptional dimensional accuracy, a crucial factor in medical equipment where tolerances can be extremely tight. The ability to produce parts that fit perfectly ensures optimal functionality in medical applications.

2. Material Efficiency

With die-casting, manufacturers can use materials more efficiently. The process minimizes waste compared to other manufacturing methods, making it a more sustainable option. Additionally, the ability to produce complex geometries reduces the need for assembly, further enhancing material efficiency.

3. Cost-Effectiveness

While the initial investment in die-casting molds can be high, the long-term cost savings are significant. The efficiency of the process allows for rapid production, reducing labor costs and manufacturing time. Moreover, the durability of die-casted parts leads to lower replacement costs over time.

4. Enhanced Strength and Durability

Parts produced through die-casting exhibit superior strength and durability. The high-pressure injection process aligns metal molecules more densely, resulting in parts that can withstand rigorous use in medical settings.

5. Aesthetically Pleasing Finishes

The die-casting process can produce parts with smooth surfaces, reducing the need for additional finishing work. This not only saves time but also ensures that the final product is visually appealing, an essential aspect in medical equipment design.

Applications of Die-Casting in Medical Equipment

The versatility of die-casting allows it to be used in various medical equipment applications:

1. Surgical Instruments

Precision is vital in surgical instruments, and die-casted parts provide the necessary accuracy and durability.

2. Diagnostic Equipment

Devices such as ultrasound machines and MRI scanners benefit from die-casting components that ensure reliability and performance.

3. Implant Devices

Die-casting can produce components for implants that require high strength and corrosion resistance.

Comparing Die-Casting to Other Manufacturing Processes

While die-casting has many advantages, it is essential to consider how it stacks up against other manufacturing methods, such as injection molding and machining.

1. Die-Casting vs. Injection Molding

Both processes offer excellent precision, but die-casting typically has better material efficiency. Injection molding, however, can be more suitable for plastics rather than metals.

2. Die-Casting vs. Machining

Machining can achieve high precision but is often slower and more expensive than die-casting due to material waste. Die-casting allows for quicker production of complex shapes.

Challenges in Die-Casting Medical Equipment Parts

Despite its many advantages, die-casting is not without challenges:

1. Initial Setup Costs

The cost of creating molds for die-casting can be substantial, which may deter small manufacturers.

2. Design Limitations

Some complex designs may not be feasible with die-casting, requiring careful consideration during the design phase.

3. Material Selection

Choosing the right metal for die-casting is critical, as different metals can affect the properties of the finished parts.

Future Trends in Die-Casting for Medical Equipment

As technology advances, so does the die-casting process. Some emerging trends include:

1. 3D Printing Integration

The integration of 3D printing with die-casting may improve mold design and reduce initial costs.

2. Smart Die-Casting Technologies

Incorporating smart technology in die-casting machines could enhance monitoring, leading to better quality control.

3. Sustainable Practices

With increasing focus on sustainability, manufacturers are exploring eco-friendly materials and processes in die-casting.

FAQs About Die-Casting in Medical Equipment Manufacturing

1. What metals are commonly used in die-casting for medical equipment?

Common metals include aluminum, zinc, and magnesium due to their favorable properties such as strength and lightweight characteristics.

2. How does die-casting ensure part quality?

Die-casting involves stringent quality control measures, including dimensional checks and material testing, to ensure that parts meet industry standards.

3. Can die-casting be used for prototypes?

Yes, die-casting can be utilized for prototypes, although it may be more cost-effective for larger production runs.

4. What are the environmental impacts of die-casting?

Die-casting is generally more sustainable than other methods, as it minimizes waste and can use recyclable materials.

5. Is die-casting suitable for small production runs?

Die-casting is most cost-effective for larger production runs due to the initial setup costs associated with mold creation.

Conclusion

In summary, die-casting stands out as a vital process in the manufacturing of medical equipment due to its several advantages, including precision, efficiency, and durability. While there are challenges, the benefits far outweigh them, making die-casting a preferred choice for manufacturers in the medical industry. As technology continues to advance, we anticipate even greater innovations in die-casting, further enhancing its role in producing high-quality medical components. By choosing die-casting, manufacturers not only meet stringent regulatory standards but also contribute to the overall advancement of medical technology.