Innovations in Customized Precision Casting Tooling for Enhanced Heat Treatment

Table of Contents

1. Introduction to Customized Precision Casting Tooling

2. The Importance of Heat Treatment in Manufacturing

3. Innovations in Casting Tooling

3.1 Advanced Materials for Tooling

3.2 Computer-Aided Design (CAD) in Tooling Development

3.3 Additive Manufacturing Techniques

4. Enhancements in Heat Treatment Processes

4.1 Controlled Atmosphere Heat Treatment

4.2 Automation and Smart Technology

5. Case Studies: Successful Implementation of Innovations

6. Benefits of Customized Precision Casting Tooling

7. Challenges and Solutions in Adoption

8. The Future of Customized Precision Casting Tooling

9. FAQs

10. Conclusion

1. Introduction to Customized Precision Casting Tooling

In the competitive landscape of manufacturing, the demand for **high-quality components** has never been greater. Customized precision casting tooling plays a pivotal role in meeting these demands by ensuring that parts are produced with the utmost accuracy and efficiency. This article delves into the latest innovations in this field, focusing on how they enhance the heat treatment process, ultimately leading to better product performance and longevity.

2. The Importance of Heat Treatment in Manufacturing

Heat treatment is a critical process in metallurgy aimed at altering the physical and sometimes chemical properties of a material. This process improves various characteristics, including **hardness, strength, ductility, and wear resistance**. In the realm of casting, effective heat treatment is essential for ensuring that the final products meet the stringent requirements of various industries, such as automotive, aerospace, and construction.

3. Innovations in Casting Tooling

The landscape of customized precision casting tooling is evolving rapidly. New technologies and materials are paving the way for enhanced performance and capabilities.

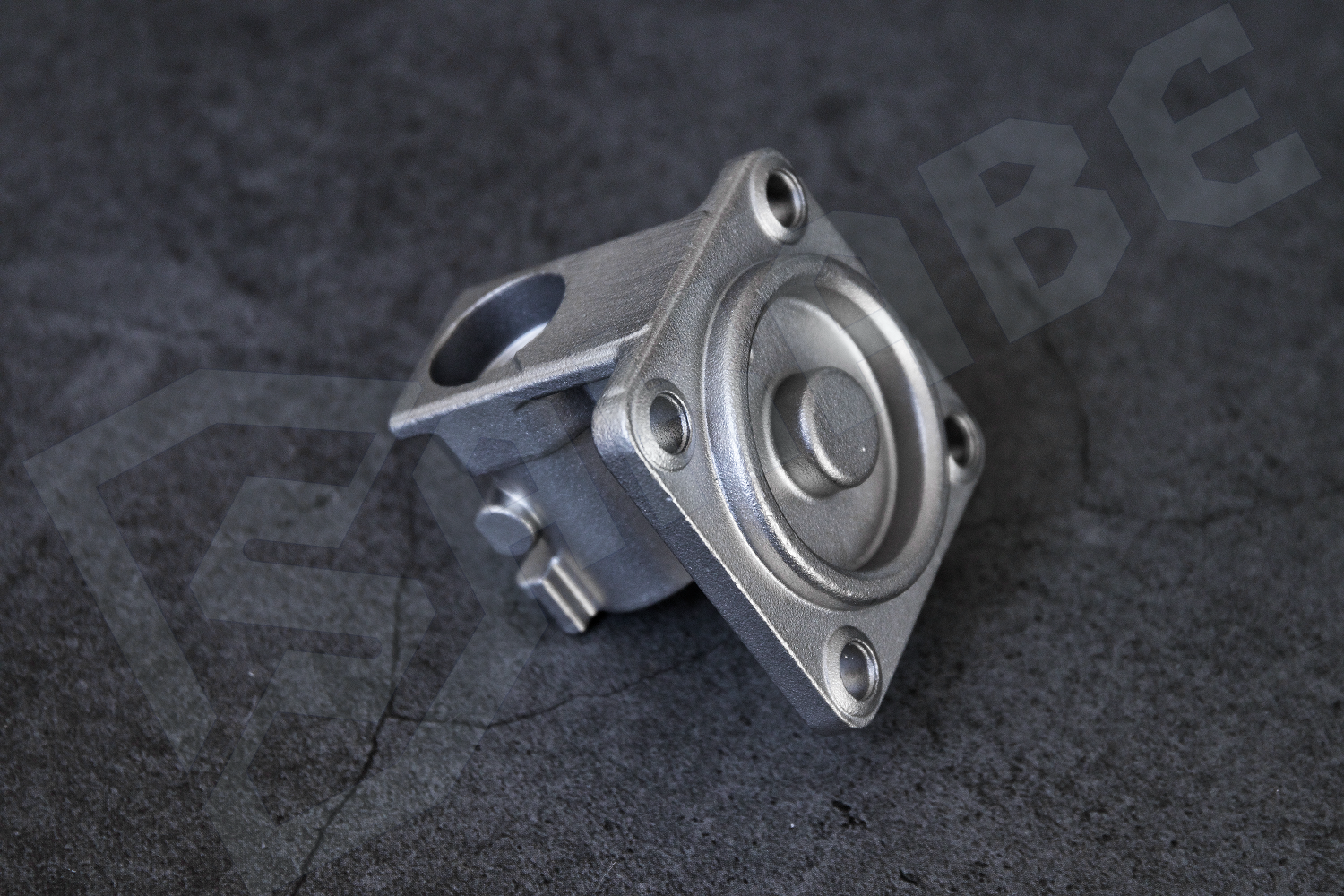

3.1 Advanced Materials for Tooling

The introduction of advanced materials, such as **high-performance alloys and composites**, has significantly improved the durability and functionality of casting tools. These materials can withstand extreme temperatures and corrosive environments, making them ideal for heat treatment applications.

3.2 Computer-Aided Design (CAD) in Tooling Development

Computer-Aided Design (CAD) has revolutionized the way tooling is developed. With CAD software, manufacturers can create highly detailed and precise designs for their casting tools. This enhances the ability to simulate the heat treatment process, allowing for better predictions of how the tool will perform under various conditions.

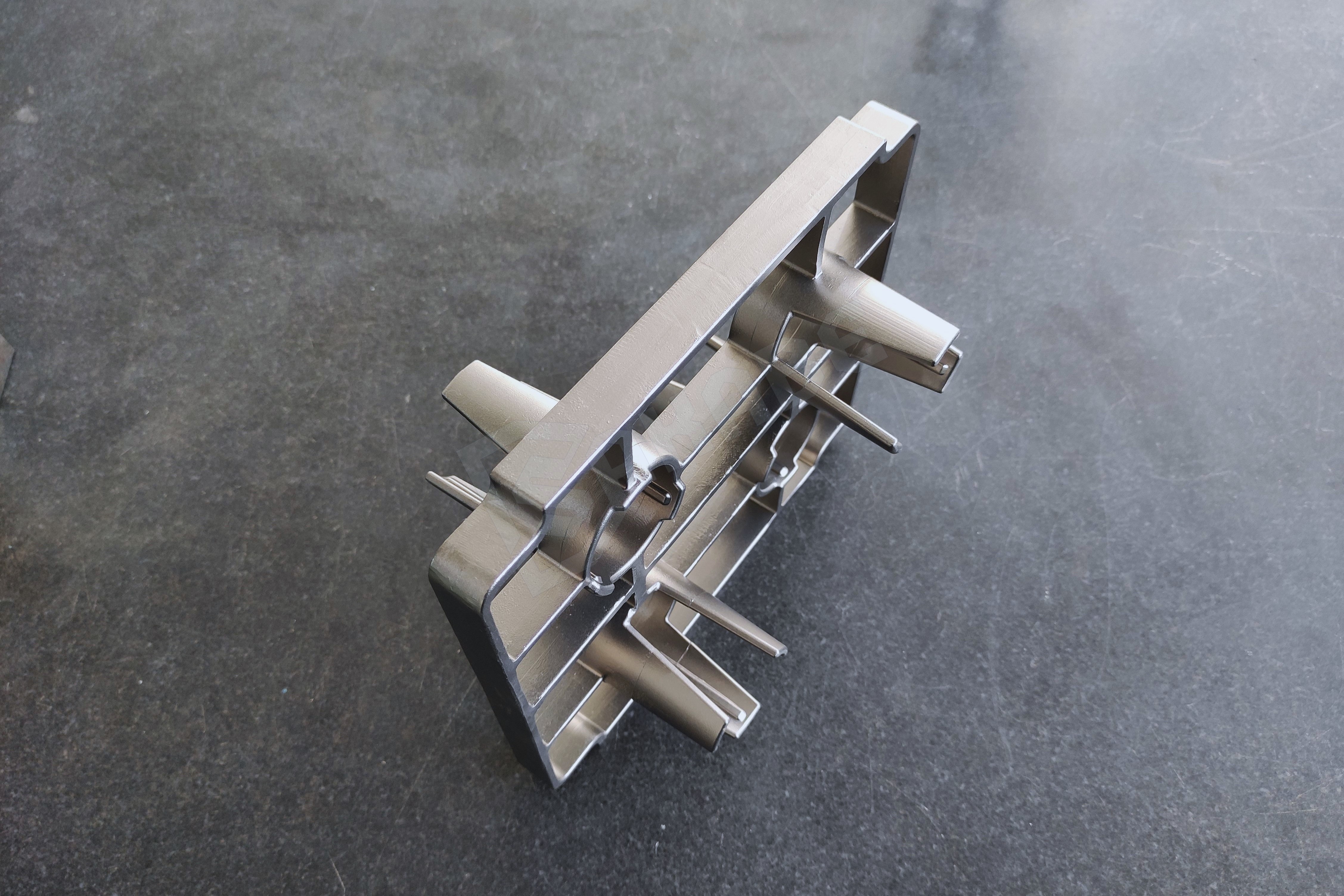

3.3 Additive Manufacturing Techniques

Additive manufacturing, also known as 3D printing, is redefining the production of customized precision casting tooling. This technology enables manufacturers to create complex geometries and intricate designs that were previously impossible to achieve. It reduces material waste and shortens lead times, allowing for more efficient production processes.

4. Enhancements in Heat Treatment Processes

Innovations in casting tooling are not only about the tools themselves but also encompass advancements in the heat treatment processes they facilitate.

4.1 Controlled Atmosphere Heat Treatment

Controlled atmosphere heat treatment (CAHT) involves subjecting materials to specific environmental conditions during the heating process. This method enhances the quality of the heat treatment by minimizing oxidation and contamination, leading to improved material properties. Customized precision casting tools designed for CAHT can maximize efficiency and effectiveness.

4.2 Automation and Smart Technology

The integration of automation and smart technology into heat treatment processes is transforming how manufacturers operate. Automated systems can monitor and adjust parameters in real-time, ensuring optimal conditions are maintained throughout the heat treatment cycle. This leads to consistent results and reduces the potential for human error.

5. Case Studies: Successful Implementation of Innovations

Several companies have successfully adopted these innovations, showcasing their benefits in real-world applications. For instance, a leading automotive manufacturer implemented advanced CAD tools and additive manufacturing techniques to streamline their tooling production. As a result, they experienced a **30% reduction in lead time** and a significant improvement in product quality.

6. Benefits of Customized Precision Casting Tooling

The advantages of customized precision casting tooling are manifold:

- **Enhanced Accuracy**: Tailored tools ensure that components meet exact specifications.

- **Increased Efficiency**: Innovations in tooling reduce production time and waste.

- **Improved Product Lifespan**: Quality tooling contributes to better heat treatment outcomes, enhancing the durability of the final product.

- **Cost Savings**: Streamlined processes and reduced material waste translate to lower manufacturing costs.

7. Challenges and Solutions in Adoption

While the benefits of innovations in casting tooling are clear, challenges remain in their adoption. Resistance to change, high initial investment, and the need for skilled personnel can hinder progress. However, companies can address these challenges through effective training programs, gradual integration of new technologies, and collaboration with technology providers.

8. The Future of Customized Precision Casting Tooling

The future of customized precision casting tooling looks promising, with continuous advancements in materials science and manufacturing technologies. Emerging trends, such as the use of **artificial intelligence** for predictive analytics and the development of more sustainable materials, will further enhance the capabilities and sustainability of casting processes.

9. FAQs

1. What is customized precision casting tooling?

Customized precision casting tooling refers to tools specifically designed to create high-accuracy casting components tailored to meet specific manufacturing requirements.

2. Why is heat treatment important in casting?

Heat treatment is vital as it improves the mechanical properties of cast components, ensuring they can withstand the operational demands of various applications.

3. What advancements have been made in casting tooling materials?

Recent innovations include the use of high-performance alloys and advanced composites that enhance durability and performance in extreme conditions.

4. How does CAD software benefit tooling development?

CAD software allows for precise design, simulation of tooling performance, and better communication between design and manufacturing teams.

5. What role does automation play in heat treatment processes?

Automation enhances the consistency and efficiency of heat treatment by allowing real-time monitoring and adjustments to process parameters.

10. Conclusion

The innovations in customized precision casting tooling for enhanced heat treatment represent a significant leap forward in manufacturing technology. As industries continue to demand higher quality and more efficient production methods, these advancements will play a critical role in shaping the future of casting processes. Embracing these innovations not only leads to better products but also positions manufacturers for long-term success in an increasingly competitive market. By focusing on continuous improvement and adaptation, businesses can harness the power of these technologies to drive growth and sustainability.