Is China Metal Casting Services for Textile Machine Parts the Key to Improving Mechanical Performance and Production Efficiency

In the realm of manufacturing and processing machinery, particularly in the field of textile machinery, metal casting services play a crucial role. China, being one of the leading countries in manufacturing, offers a wide array of metal casting solutions tailored to meet the specific needs of the textile industry. These services encompass the production of various components and parts essential for the operation of textile machinery, such as gears, frames, and other intricate components.

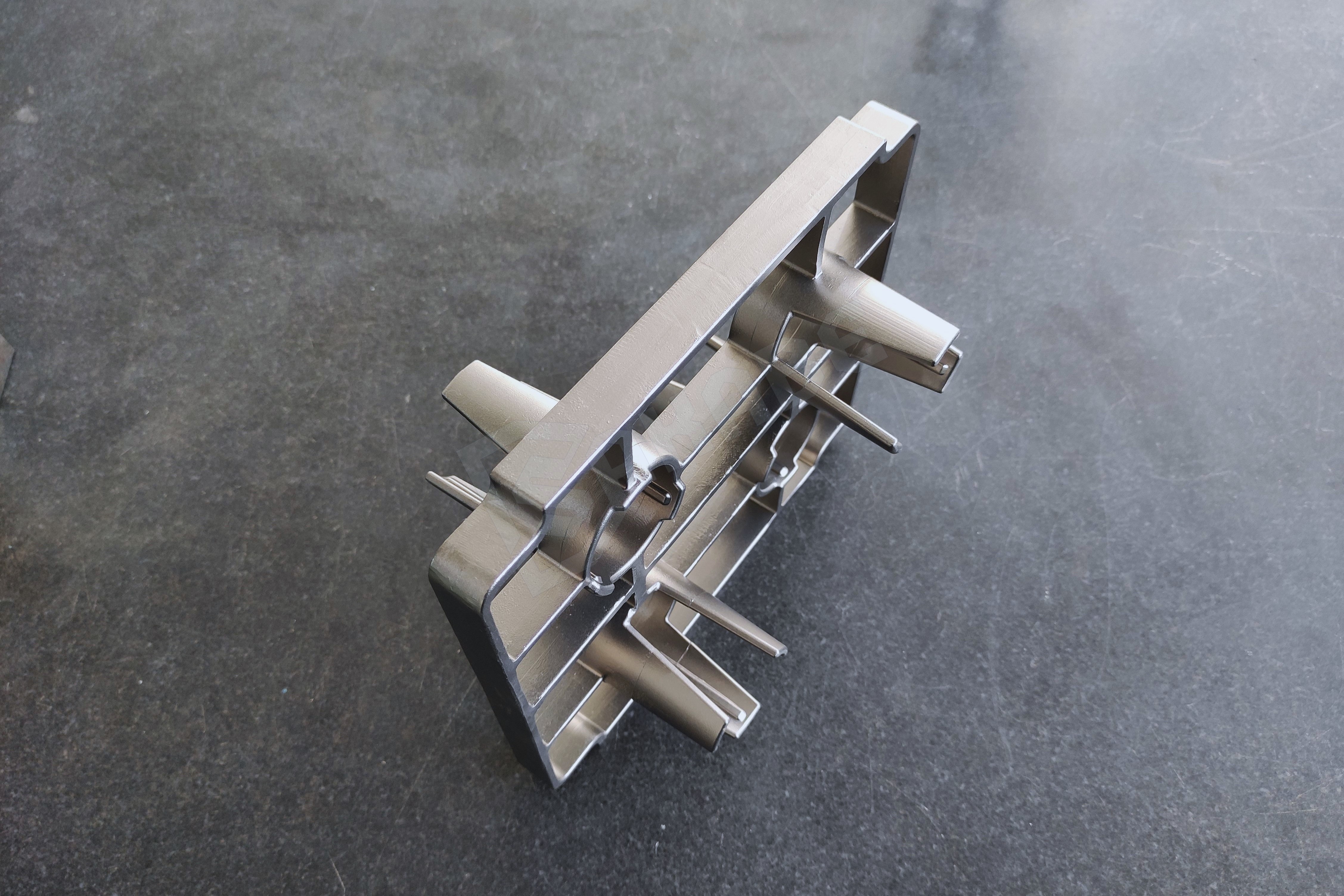

Metal casting services for textile machine parts are a versatile process that allows for the creation of complex shapes and structures that are essential in the textile machinery sector. The process involves pouring molten metal into a mold to form a specific shape, which is then allowed to cool and solidify. The ability to produce high-quality components with precise dimensions makes metal casting an ideal choice for manufacturers seeking efficiency and reliability in their machinery.

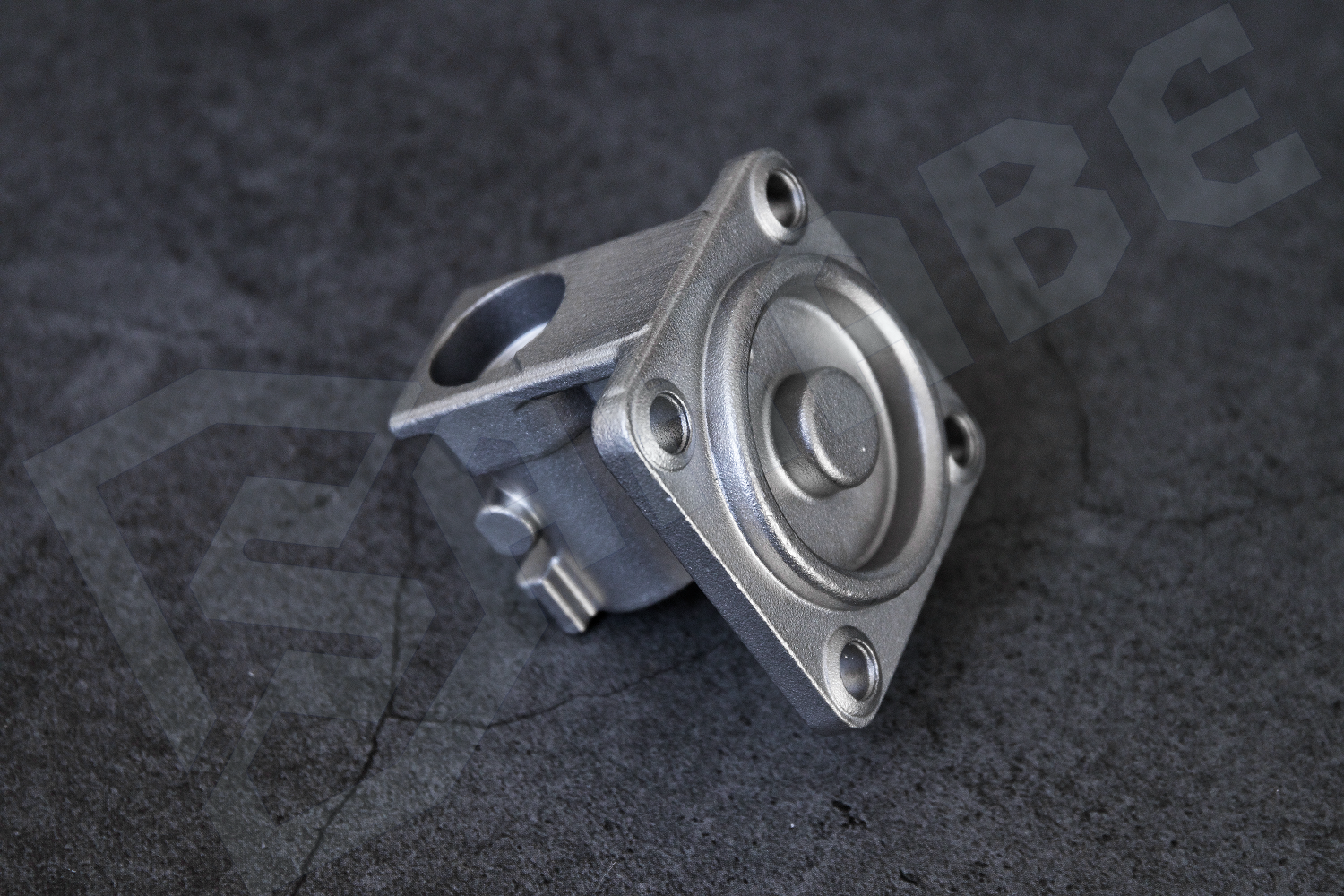

One of the significant advantages of utilizing metal casting services in the textile industry is the ability to work with a variety of metals, including iron, steel, and aluminum. Each of these materials has unique properties that can be leveraged to enhance the performance and durability of textile machinery. For instance, aluminum castings are lightweight and resistant to corrosion, making them suitable for machine components that require both strength and agility.

Moreover, advancements in technology have significantly improved the metal casting process. Innovations such as computer-aided design (CAD) and 3D printing have enabled manufacturers to create more complex and customized molds, leading to greater efficiency and reduced production times. This is particularly advantageous in the textile industry, where the demand for customized machinery is increasing.

Additionally, choosing a reputable metal casting service provider in China ensures that manufacturers benefit from high standards of quality control. Quality assurance measures, such as non-destructive testing and metallurgical analysis, are often employed to guarantee the integrity and performance of the cast components. This focus on quality not only enhances the reliability of the machinery but also contributes to minimizing downtime and maintenance costs.

Lastly, as the textile industry continues to evolve, so do the requirements for machinery. Metal casting services in China are well-positioned to adapt to these changes, offering scalable solutions that cater to both small-scale and large-scale manufacturing processes. By partnering with experienced casting service providers, textile manufacturers can stay ahead of the curve and implement the latest technological advancements to improve their production capabilities.

In conclusion, metal casting services for textile machinery in China represent a pivotal aspect of the manufacturing landscape. By understanding the benefits and advancements in this sector, businesses can make informed decisions that drive growth and innovation in their operations. Whether it's enhancing machinery performance or ensuring quality control, metal casting remains an integral component of successful textile manufacturing.